2077

Technical Committee 207 /

Comité technique 207

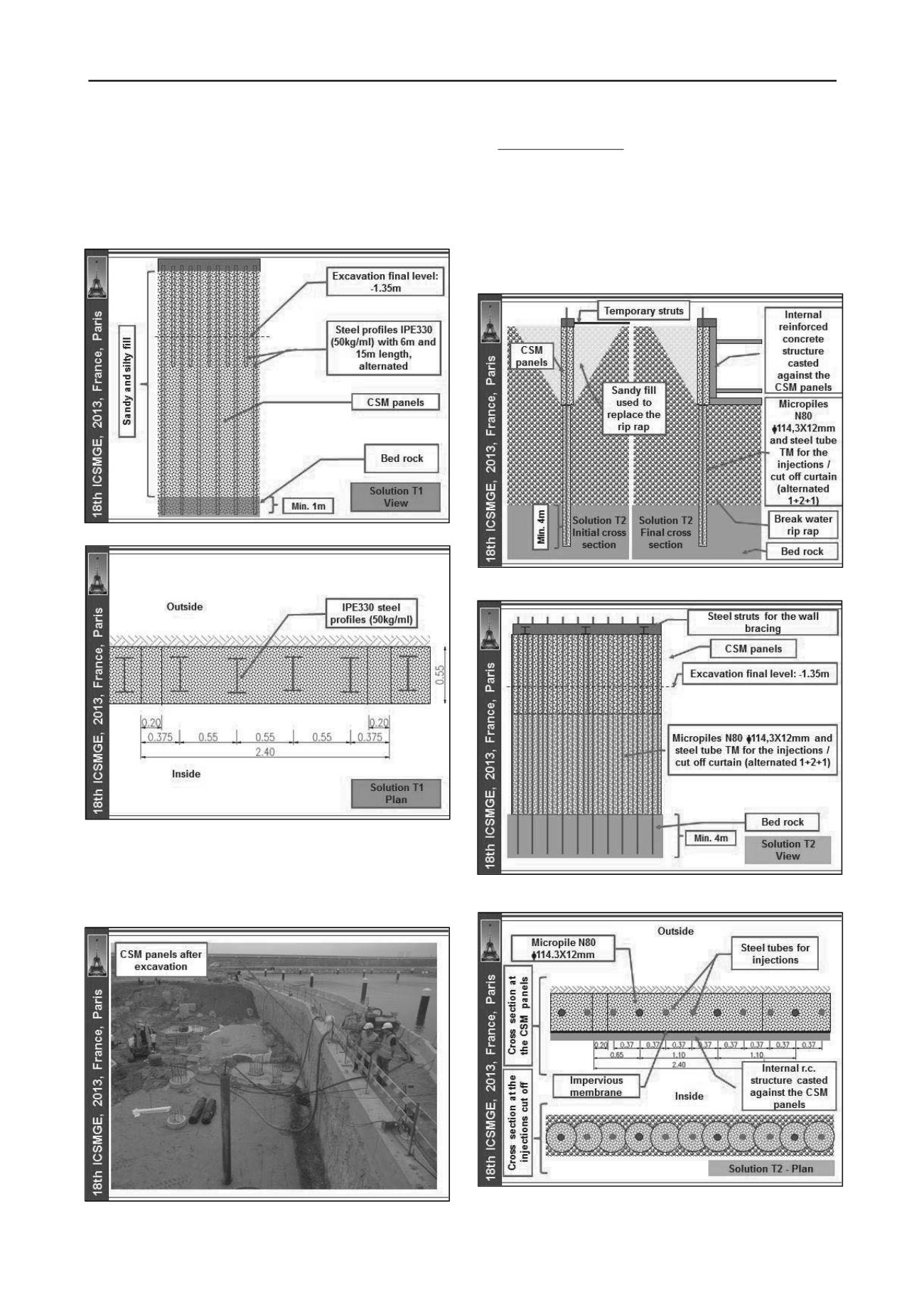

The soil - cement panels, with UCS resistance not lesser

than 4MPa, were reinforced with vertical IPE330 steel profiles

(Euronorm 19-57), spaced 0,55m in average, in order to resist to

the earth and water pressures, as well as to ensure a better

control of the deformations. The steel profiles were placed

inside the panels, before the cement started the curing process

and capped by a reinforced concrete beam (Figure 8 to 11).

Figure 9. Solution T1 – view.

Figure 10. Solution T1 – plan.

The soil - cement panels will be demolished from the

internal structure foundation level to the top, in order to allow

the reinforced concrete (r.c.) wall with a very good finishing

face, being visible from the adjacent marina, (Figure 12).

Figure 11. Solution T1 – view of soil-cement panels after excavation.

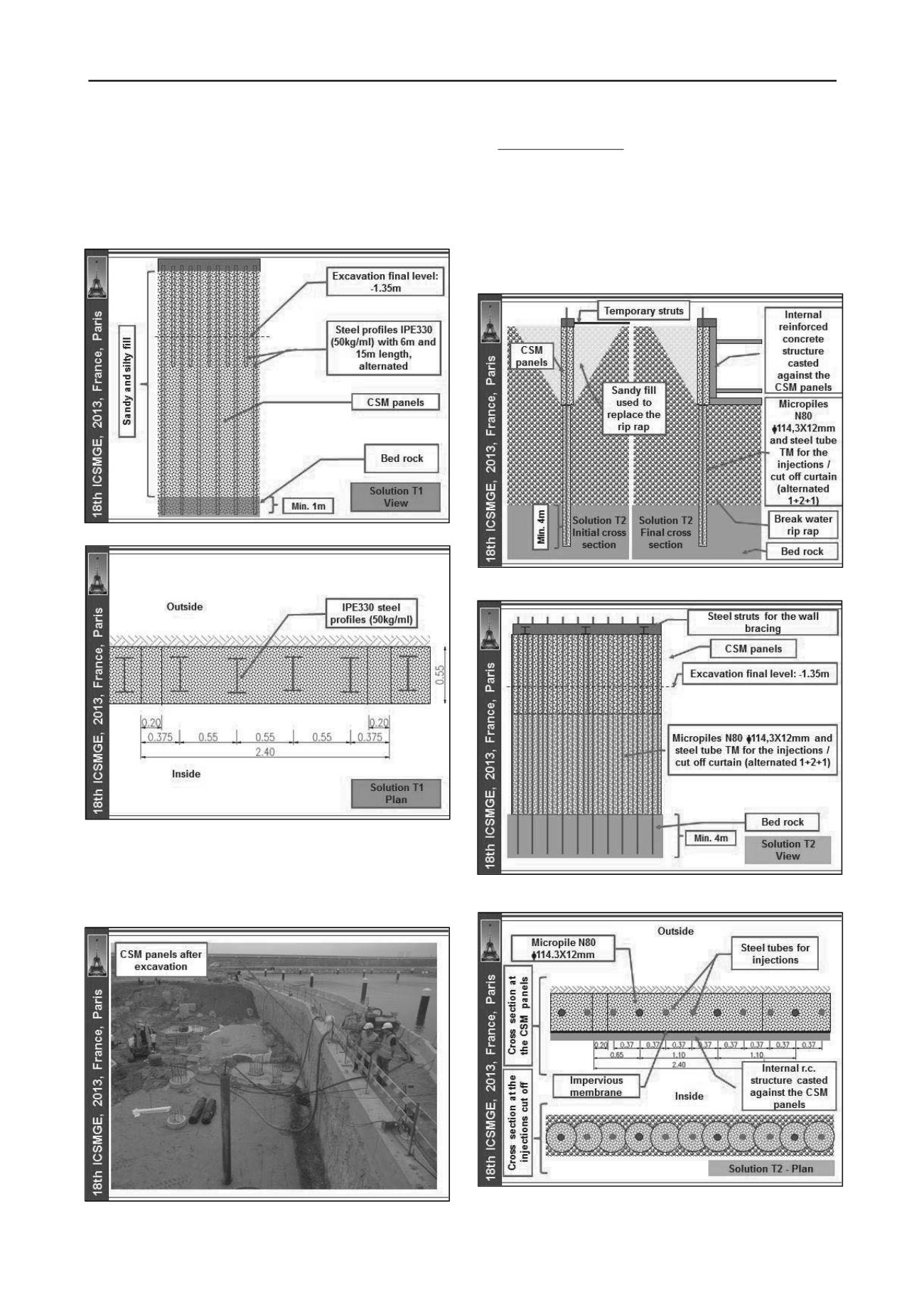

Solution type 2 (T2): soil - cement panels with a cross

section of 2,4 x 0,5m

2

, including 0,20m of overlapping on a

height of approximately 6.5m, correspondent to the previous

excavation depth, performed in order to replace the break water

rip rap by a sandy fill. The panels were built using the CSM

technology. Bellow the soil - cement panels the cofferdam cut

off effect was assured through a curtain, performed using

alternated slurry cement injections through steel tubes and

micropiles N80

114,3x12mm, those also with foundation

purposes and sealed 4m on the bed rock (Figures 12 to 15).

Figure 12. Solution T2 – initial and final cross section.

Figure 13. Solution T2 – view.

Figure 14. Solution T2 – plan.