1540

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

for values of fines content greater than 44 % (Xenaki and

Athanasopoulos, 2003). Cyclic strength of silty sands with 15%

fines has only one-half of the resistance to liquefaction of clean

sands at the same effective confining pressure (Troncoso, 1986).

Addition of nonplastic silt with clean sand results in increasing

pore pressure up to a limiting value that corresponds to 30% in

silt content. Further, addition of low plasticity silt to sand has no

significant effect on the generated pore pressures, up to 60% in

silt content (Erten and Maher, 1995). Liquefaction of soils

occurred with upto 70% fines and 10% clay fraction during

Mino-Owar, Tohankai and Fukui earthquakes (Kishida, 1969).

Cyclic tests on Ottawa sands showed that, for a constant dry

density, the liquefaction resistance decreased as fines were

added to sand (Shen et al, 1977). At a constant relative density,

additional fines (10% to 50%) acted to increase the liquefaction

resistance of sand (Amini and Qi, 2000). Liquefaction of silty

soils found that increased plasticity results in an increased

cyclic strength and silty soils, having a plasticity index of 15 or

more the state of initial liquefaction never developed. It has

been demonstrated that the fine grained tailings that were

identified as being nonplastic exhibited much smaller cyclic

strength than the tailings having a plasticity index of 15-20

(Ishihara et al, 1980). Specimens tested using a fast rise time

square wave form, shows strength value about 15% less than

those tested using a sine wave loading.

Cyclic strength of the specimens prepared using the dry

method is on the order of half the strength of the specimens

prepared using the wet method (Marshall et al, 1976). The effect

of relative density on shear modulus of dry and saturated sands

is significant in the small strain levels (0.1% to 0.5%) and

thereafter the effect of relative density on shear modulus with

increase in shear strain is not significant. The damping ratios of

dry and saturated sands increase with increase in shear strain

and the effect of relative density on damping is not very

significant in both cases. There is a reduction in shear modulus

and an increase in damping at large shear strain levels

(Kokusho, 1980; Dinesh, 2004). Relative density has no

significant influence on the dynamic properties of soils in the

large strain (greater than 1%) levels, but it has considerable

influence at small strain levels (Sitharam et al, 2004ab).

This paper summarized the liquefaction potential and

dynamic properties of a local sandy soil at constant relative

density and constant effective confining pressure. Effect of

nonplastic silt on cyclic shear strength of fine sand is also

present in this paper.

3 EXPERIMENTAL INVESTIGATIONS

3.1

Soil sampling and characterization

A fine sand (hereinafter called Sand-01) sample was collected

from the site close to Piyain river of Jaflong, Sylhet,

Bangladesh. Table 1 gives the summary of index properties of

the sand sample collected and used for testing. It is clear from

the index properties that the soils contain a large percentage of

fine sand with appreciable amount of fines that are more prone

to liquefaction. A fine sand (Hereinafter called Sand-02) and a

nonplastic silt was collected from Mawa Padma Bridge site.

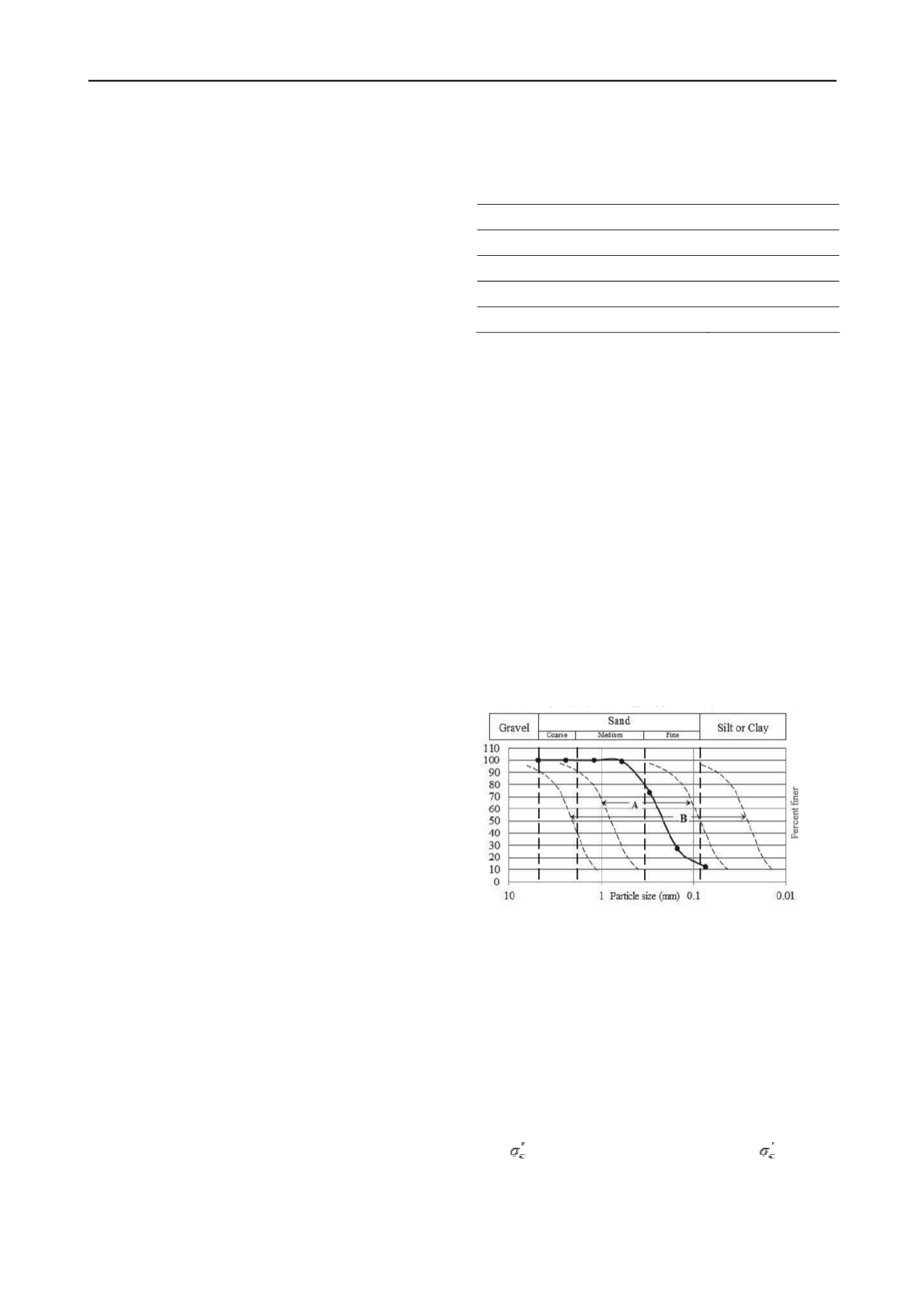

Figure 1 shows the grain size distribution of the Sand-01 as well

as limits in the gradation curves separating liquefiable and non-

liquefiable soils (Tsuchida, 1970). Fineness modulus and D

50

of

Sand-02 is 0.92 and 0.20 mm respectively. Sand-02 is finer than

Sand-01 (FM=1.01).

3.2

Sample preparation

Soil specimens of size 71 mm diameter and 143 mm in height

were prepared using wet tamping technique. The sand was

initially mixed in a container with 8% to 10% moisture. Then

the wet sand was poured into the mold in 5 layers and

compacted in 5 layers using 35.5 mm diameter circular

aluminum tamper, weighing about 800 g at a relative density of

55%.

Table 1. Index properties of sand sample used for cyclic triaxial test.

Index Properties

Value

Specific Gravity

2.65

Fineness Modulus

1.01

Coarse, Medium, Fine sand and Silt %

0.2, 9.8, 78.3 and 11.7

Maximum and Minimum Density

16.7 and 12.15 kN/m

3

The soil specimen was sealed in a water tight rubber

membrane with O-ring and confined in a triaxial chamber where

it was subjected to a confining pressure of 20 kPa. In order to

improve the initial saturation of the specimen, carbon dioxide

(CO

2

) was allowed to flow through the specimen at a low

pressure (less than 20 kPa) in order to replace the air in the

specimen pores. After 30 minutes, the flow of carbon dioxide

(CO

2

) was stopped and a tank of de-aired water was attached to

the drainage line on the bottom platen. The de-aired water was

then allowed to flow upward through the specimen in order to

saturate the specimen. Once the desired volume of de-aired

water had flowed through the specimen, the drainage valves on

the cell were again closed and the de-aired water line removed.

The specimens were then saturated with de-aired water using

backpressure saturation. The back pressure was increased

gradually while maintaining the effective confining pressure at

10 kPa. This process was continued until the Pore Pressure

Parameter B (B = Δu/Δσ

c

, where, Δu = Change in specimen

pore pressure and Δσ

c

= Change in confining pressure)

exceeded 0.95. Following saturation, the sand specimen was

isotropically consolidated to an effective stress of 50 kPa.

Figure 1. Grain size distribution curve and limits in the gradation curves

(A- Boundaries for most liquefiable soil, B-Boundaries for Potentially

liquefiable soil) separating liquefiable and non-liquefiable soils.

3.3

Cyclic loading and data acquisition

Before the application of cyclic load an air pocket at the top of

the triaxial chamber was formed by draining water from the cell

without allowing the cell pressure to drop. Then cyclic loading

was applied on the soil specimens using the stress-controlled

method. The cyclic triaxial strength tests were conducted under

undrained conditions to simulate essentially undrained field

conditions during an earthquake or dynamic loading. The tests

were conducted at a constant Cyclic Stress Ratio (CSR =

(σ

dc

/2 , where (σ

dc

= cyclic deviator stress and

= effective

confining pressure). CSR was varied from 0.15 to 0.45 at the

interval of 0.05. In the entire test program, a harmonic loading

was applied using sine wave with a frequency of 1 Hz, the

maximum peak-peak axial strain 10%, the number of cycles

limited to 100 cycles and a recording speed of 50 numbers of

for values of fines content greater than 44 % (Xenaki and

Athanasopoulos, 2003). Cyclic strength of silty sands with 15%

fines has only one-half of the resistance to liquefaction of clean

sands at the same effective confining pressure (Troncoso, 1986).

Addition of nonplastic silt with clean sand results in increasing

pore pressure up to a limiting value that corresponds to 30% in

silt content. Further, addition of low plasticity silt to sand has no

significant effect on the generated pore pressures, up to 60% in

silt content (Erten and Maher, 1995). Liquefaction of soils

occurred with upto 70% fines and 10% clay fraction during

Mino-Owar, Tohankai and Fukui earthquakes (Kishida, 1969).

Cyclic tests on Ottawa sands showed that, for a constant dry

density, the liquefaction resistance decreased as fines were

added to sand (Shen et al, 1977). At a constant relative density,

additional fines (10% to 50%) acted to increase the liquefaction

resistance of sand (Amini and Qi, 2000). Liquefaction of silty

soils found that increased plasticity results in an increased

cyclic strength and silty soils, having a plasticity index of 15 or

more the state of initial liquefaction never developed. It has

been demonstrated that the fine grained tailings that were

identified as being nonplastic exhibited much smaller cyclic

strength than the tailings having a plasticity index of 15-20

(Ishihara et al, 1980). Specimens tested using a fast rise time

square wave form, shows strength value about 15% less than

those tested using a sine wave loading.

Cyclic strength of the specimens prepared using the dry

method is on the order of half the strength of the specimens

prepared using the wet method (Marshall et al, 1976). The effect

of relative density on shear modulus of dry and saturated sands

is significant in the small strain levels (0.1% to 0.5%) and

thereafter the effect of relative density on shear modulus with

increase in shear strain is not significant. The damping ratios of

dry and saturated sands increase with increase in shear strain

and the effect of relative density on damping is not very

significant in both cases. There is a reduction in shear modulus

and an increase in damping at large shear strain levels

(Kokusho, 1980; Dinesh, 2004). Relative density has no

significant influence on the dynamic properties of soils in the

large strain (greater than 1%) levels, but it has considerable

influence at small strain levels (Sitharam et al, 2004ab).

This paper summarized the liquefaction potential and

dynamic properties of a local sandy soil at constant relative

density and constant effective confining pressure. Effect of

nonplastic silt on cyclic shear strength of fine sand is also

present in this paper.

3 EXPERIMENTAL INVESTIGATIONS

3.1

Soil sampling and charact rization

A fine sand (hereinafter called Sand-01) sample was collected

from the site close to Piyain river of Jaflong, Sylhet,

Bangladesh. Table 1 gives the summary of index properties of

the sand sample collected and used for testing. It is clear from

the index properties that the soils contain a large percentage of

fine sand with appreciable amount of fines that are more prone

to liquefaction. A fine sand (Hereinafter called Sand-02) and a

nonplastic silt was collected from Mawa Padma Bridge site.

Figure 1 shows the grain size distribution of the Sand-01 as well

as limits in the gradation curves separating liquefiable and non-

liquefiable soils (Tsuchida, 1970). Fineness modulus and D

50

of

Sand-02 is 0.92 and 0.20 mm respectively. Sand-02 is finer than

Sand-01 (FM=1.01).

3.2

Sample prepar ti

Soil specimens of size 71 mm diameter and 143 mm in height

were prepared using wet tamping technique. The sand was

initially mixed in a container with 8% to 10% moisture. Then

the wet sand was poured into the mold in 5 layers and

compacted in 5 layers using 35.5 mm diameter circular

aluminum tamper, weighing about 800 g at a relative density of

55%.

Table 1. Index properties of sand sample used for cyclic triaxial test.

Index Properties

Value

Specific Gravity

2.65

Fineness Modulus

1.01

Coarse, Medium, Fine sand and Silt %

0.2, 9.8, 78.3 and 11.7

Maximum and Minimum Density

16.7 and 12.15 kN/m

3

The soil specimen was sealed in a water tight rubber

membrane with O-ring and confined in a triaxial chamber where

it was subjected to a confining pressure of 20 kPa. In order to

improve the initial saturation of the specimen, carbon dioxide

(CO

2

) was allowed to flow through the specimen at a low

pressure (less than 20 kPa) in order to replace the air in the

specimen pores. After 30 minutes, the flow of carbon dioxide

(CO

2

) was stopped and a tank of de-aired water was attached to

the drainage line on the bottom platen. The de-aired water was

then allowed to flow upward through the specimen in order to

saturate the specimen. Once the desired volume of de-aired

water had flowed through the specimen, the drainage valves on

the cell were again closed and the de-aired water line removed.

The specimens were then saturated with de-aired water using

backpressure saturation. The back pressure was increased

gradually while maintaining the effective confining pressure at

10 kPa. This process was continued until the Pore Pressure

Parameter B (B = Δu/Δσ

c

, where, Δu = Change in specimen

pore pressure and Δσ

c

= Change in confining pressure)

exceeded 0.95. Following saturation, the sand specimen was

isotropica ly con olid ted to an eff ctive stress o 50 kPa.

Figure 1. Grain size distribution curve and limits in the gradation curves

(A- Boundaries for most liquefiable soil, B-Boundaries for Potentially

liquefiable soil) sep rating liquefiable and non-liquefiable soils.

3.3

Cyclic loading and data acquisition

Before the application of cyclic load an air pocket at the top of

the triaxial chamber was formed by draining water from the cell

without allowing the cell pressure to drop. Then cyclic loading

was applied on the soil specimens using the stress-controlled

method. The cyclic triaxial strength tests were conducted under

undrained conditions to simulate essentially undrained field

conditions during an earthquake or dynamic loading. The tests

were conducted at a constant Cyclic Stress Ratio (CSR =

(σ

dc

/2 , where (σ

dc

= cyclic deviator stress and

= effective

confining pressure). CSR was varied from 0.15 to 0.45 at the

interval of 0.05. In the entire test program, a harmonic loading

was applied using sine wave with a frequency of 1 Hz, the

maximum peak-peak axial strain 10%, the number of cycles

limited to 100 cycles and a recording speed of 50 numbers of

pore pressure up to a limiting value that corresponds to 30% in

silt content. Further, addition of low plasticity silt to sand has no

significant effect on the generated pore pressures, up to 60% in

silt content (Erten and Maher, 1995). Liquefaction of soils

occurred with upto 70% fines and 10% clay fraction during

Mino-Owar, Tohankai and Fukui earthquakes (Kishida, 1969).

Cyclic tests on Ottawa sands showed that, for a constant dry

density, the liquefaction resistance decreased as fines were

added to sand (Shen et al, 1977). At a constant relative density,

additional fines (10% to 50%) acted to increase the liquefaction

resistance of sand (Amini and Qi, 2000). Liquefaction of silty

soils found that increased plasticity results in an increased

cyclic trength and silty soils, having plasticity index of 15 or

more the state of initial liquefaction never developed. It has

been demonstrated tha the fine grained tailings that were

i entified s b ing nonplast c exhibited much smaller cyclic

strength tha the tail ngs aving a plasticity i dex of 15-20

(Ishihara t al, 1980). Specimens tested using a fast rise time

squar wave fo m, shows strength value about 15% les than

those tested using a sin wave loading.

Cyclic st ength of the specimens prepared using the dry

method is on the order of half the strength of he spec mens

prepared using the wet method (Marshall et al, 1976). The effect

of relative densi y on hear modulus of dry and satur ted sands

i significant in the small strain levels (0.1% to 0.5%) and

thereafter the effec of relative density on sh ar mo ulu with

increase i shear strain is not significant. The damping ra s of

dry and saturated sands i crease with increase in shear s rain

and the effect of relative density on damping is not very

significant in both cases. There is a reduction in shear modulus

and an increase in damping at large shear strain levels

(Kokusho, 1980; Dinesh, 2004). R lative density has no

sign ficant influence on the dynamic properties of soils in the

lar e str in (gre ter than 1%) leve s, bu it has c nsiderable

influence t small strain levels (Sitharam et al, 2004ab).

This paper summarized

e iquefaction pot ntial and

dynamic properties of loc l sandy soil at constant relative

density and constan ffective confining pres ure. Effect of

nonpla tic silt on cyclic shear strength of fin and is also

pres nt in this pap r.

3 EXPERIMENTAL INVESTIGATIONS

3.1

Soil sampling and characterization

A f ne sand (hereinafter called Sand-01) sample was collected

from he site close to Piyain river of Jaflong, Sylhet,

Bangladesh. T ble 1 gives the summary of index properties of

the sand s mple collected and used for tes ng. It is cle r from

the index properties that the soils contain a large percentage of

fi e sand with appreciabl amount of f nes that ar more prone

t liquefaction. A fine sand (Hereinafter called Sand-02) and a

nonplastic silt was collected from Mawa Padma Bridge site.

Figure 1 shows the grain size distribution of the Sand-01 as well

as limits in the gradation curves separating liquefiable and non-

liquefiable soils ( suchida, 1970). Fineness modulus and D

50

of

Sand-02 is 0.92 and 0.20 mm respectively. Sand-02 is finer than

Sand-01 (FM=1.01).

3.2

Sample preparation

Soil speci ens of size 71 mm di eter and 143 mm in height

were prepared using wet tamping technique. The sand was

initially mixed in a container with 8% to 10% moisture. Then

the wet sand was poured into the mold in 5 layers and

compacted in 5 layers using 35.5 mm diameter circular

Index Properties

Value

Specific Gravity

2.65

Fineness Modulus

1.01

Coarse, Medium, Fine sand and Silt %

0.2, 9.8, 78.3 and 11.7

Maximum and Minimum Density

16.7 and 12.15 kN/m

3

The soil specimen was sealed in a water tight rubber

membrane with O-ring and confined in a triaxial chamber where

it was subjected to a confining pressure of 20 kPa. In order to

improve the initial saturation of the specimen, carbon dioxide

(CO

2

) was allowed to flow through the specimen at a low

pressure (less than 20 kPa) in order to replace the air in the

specimen pores. After 30 minutes, the flow of carbon dioxide

(CO

2

) was stopped and a tank of de-aired water was attach d to

the drainage line on the bottom platen. The de-aired water was

then allowed to flow upward through the specimen in order to

saturate the specimen. Onc the desired volume of de-aired

water had flowed through the specimen, the drainage valves on

the cell were again close

the de-aired water line removed.

The specimens were then saturated with de-aired water using

backpressure saturation. The back pressure was increased

gradually while maintaining the effective confining pressure at

10 kPa. This process was continued until the Pore Pressure

Parameter B (B = Δu/Δσ

c

, wh re, Δu = Change in specimen

pore pressure and Δσ

c

= Change in confining pressure)

exceeded 0.95. Following saturation, the sand specimen was

isotropically consolidated to an effective stress of 50 kPa.

Figure 1. Grain size distribution curve and limits in the gradation curves

(A- Boundaries for most liquefiable soil, B-Boundaries for Potentially

liquefiable soil) separating liquefiable and non-liquefiable soils.

3.3

Cyclic loading and data acquisition

Before the application of cyclic load an air pocket at the top of

the triaxial chamber was formed by draining water from the cell

without allowing the cell pressure to drop. Then cyclic loading

was applied on the soil specimens using the stress-controlled

method. The cyclic triaxial strength tests were conducted under

undrained conditions to simulate essentially undrained field

conditions duri g an earthquake or dynamic loading. The tests

w re conducted at a constant Cyclic Stress Ratio (CSR =

(σ

dc

/2 , where (σ

dc

= cyclic deviator stress and

= effective

confining pressure). CSR was varied from 0.15 to 0.45 at the

int rval of 0.05. In the e tire test program, a harmonic loading

was applied using s ne wav with a frequency of 1 Hz, the

maximum peak-peak axial strain 10%, the number of cycles

limited to 100 cycles and a recording speed of 50 numbers of