1549

Technical Committee 203 /

Comité technique 203

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

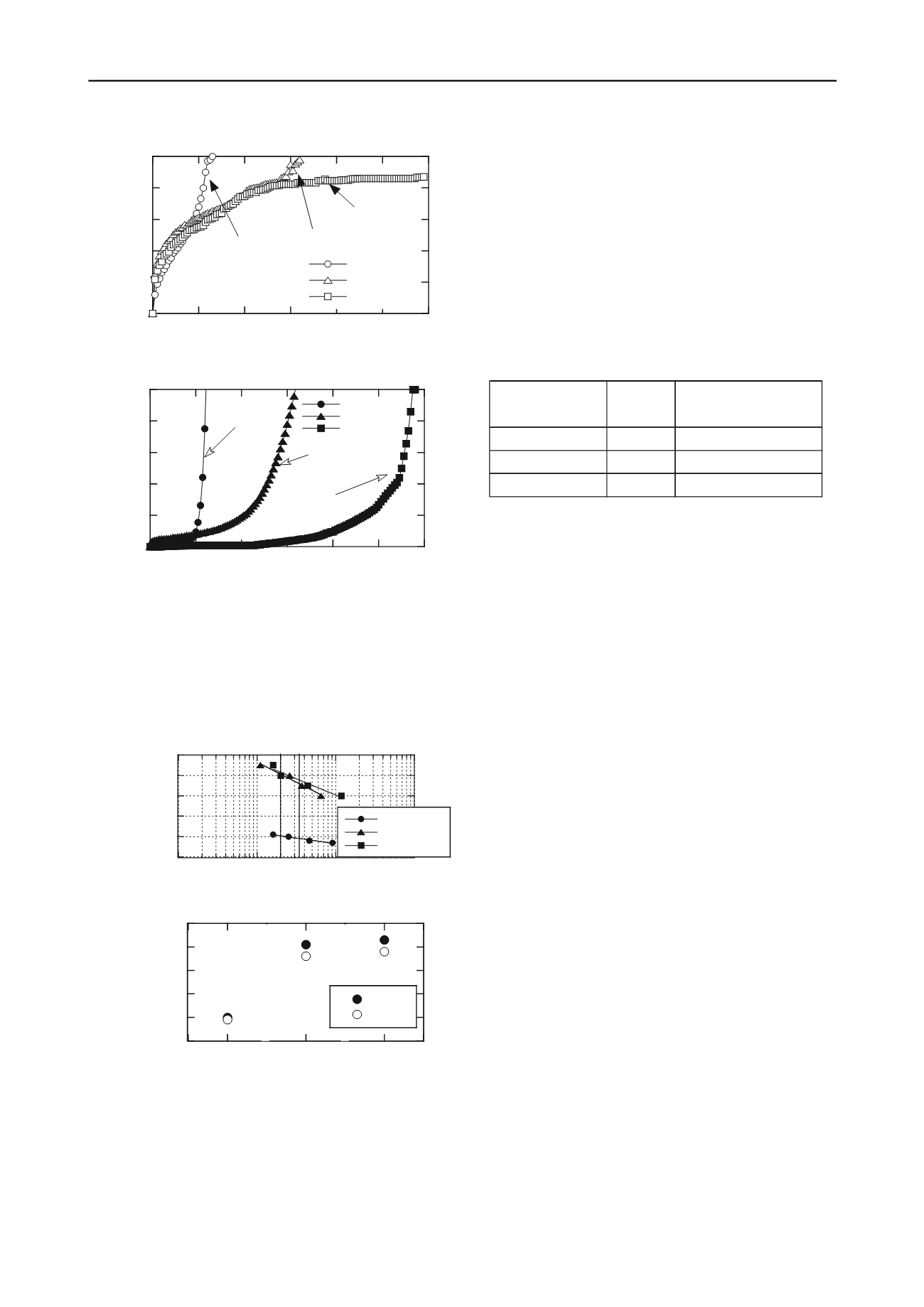

Figure 4 shows the liquefaction strength curve. For this

study, we assume that liquefaction occurs at DA = 5 %.

Focusing on the liquefaction strength N

20

, the improved soils

increased liquefaction strength by about 2.5 times, compared to

non-improved soil. The liquefaction strength required for an

earthquake of M 9.0 class such as the Great East Japan

Earthquake is assumed to be 34 times (Sezaki, 2011).

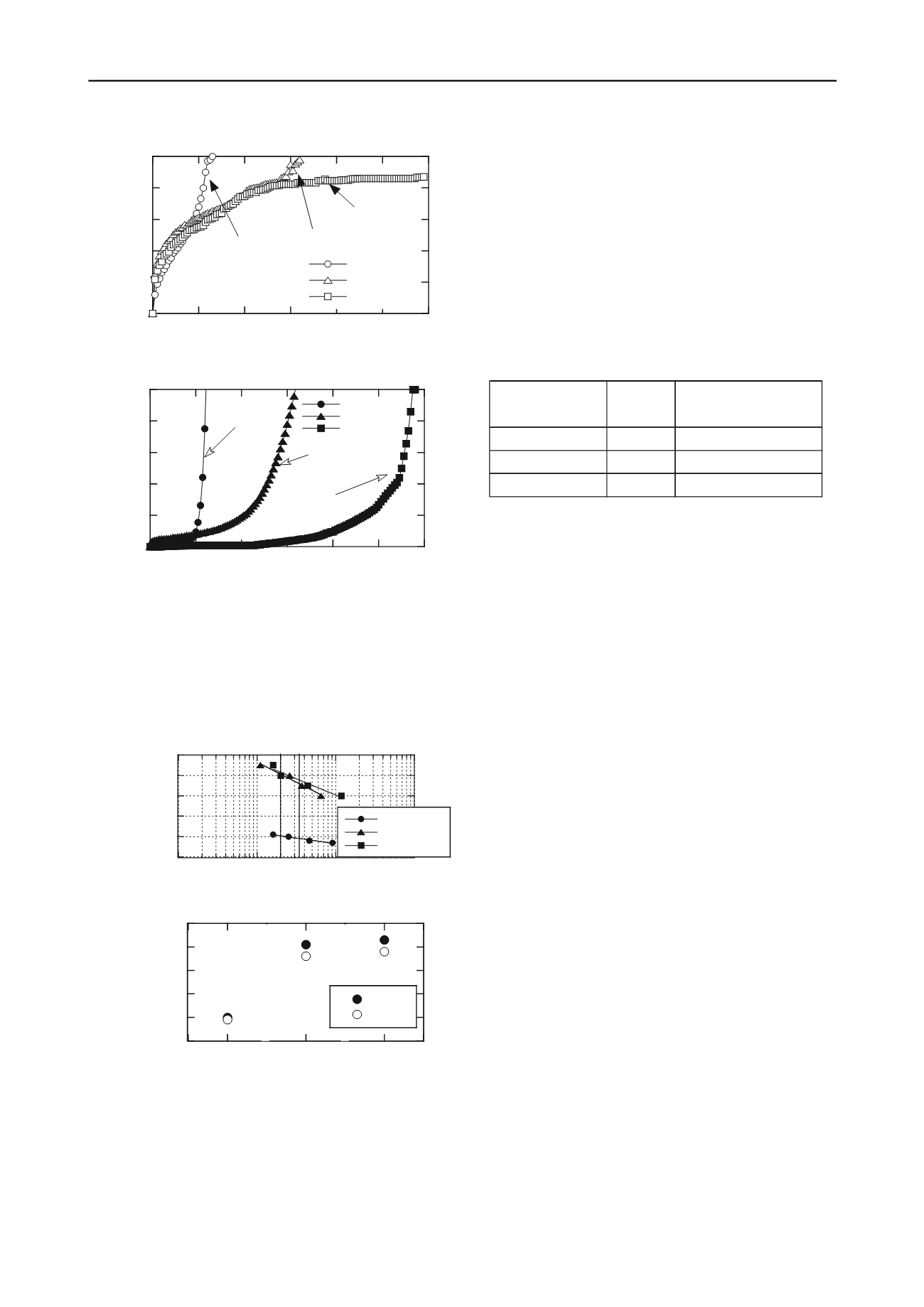

Figure 5 shows the relationships between additive

conditions and liquefaction strength. For the case of

liquefaction strength N

20

, the liquefaction strength with mixing

of solidification material makes no difference. However, for the

case of liquefaction strength N

34

, liquefaction strength of

mixing recycled Bassanite increases slightly. From this, for the

case of a large earthquake, the greater the development of

cohesions, the more chance there will be suppression of

liquefaction due to mixing of solidification material.

0

0.2

0.4

0.6

0.8

1

0 20 40 60 80 100 12

3.2 Suppression method of liquefaction by tension stiffener

Table 3 shows strength parameters determined from Mohr's

stress circles from the drained monotonic shear tests. The

cohesion increases due to an increase of the additive ratio of

tension stiffener and solidification material. These are

considered to be due to the added deformation restraint of the

specimens by the additional fibers and the interparticles force of

sand due to the cement.

Figure 6 (a) - (c) shows the effective stress path diagrams

for each condition for the undrained cyclic shear tests. (a) C =

0% and (b) C = 0% + F = 1% have the same cyclic stress ratio.

Focusing on the stress path (b) C = 0% + F = 1%, the decrease

in effective stress due to cycles is small due to the additional

fibers. The number of effective stress cycles path until the PT

line is however increased. It can be seen that there is an effect

of increasing the liquefaction resistance even with the addition

of only fibers. Then, for the case of (c) C = 1% + F = 1%, the

number of cycles for liquefaction is increased, regardless of

cyclic stress ratio. Cyclic mobility occurs after reaching the PT

line with increasing the additive ratio of the short fibers and

solidification material. These are thought to increase the

liquefaction resistance by restraint of deformation of the short

fibers and the interparticles forces of the sand due to the added

cement.

Figure 7 shows the relationships between number of cycles

and maximum pore pressure ratio for each conditions. The

development of the excess pore pressure ratio of non-improved

soil and for the addition of only short fibers reaches liquefaction

after it reaches

/p

c

’=0.6. Next, in the case of added short fibers

and solidification material, significant excess pore pressure

ratio occurs in early phases of the shear, because the cyclic

deviator stress ratio is great. But, the liquefaction does not rise

instantly. The excess pore pressure ratio approaches

/p

c

’ = 1.0

at a slow pace. This is thought to reflect the restraint of

deformation for cyclic behaviors depending on the addition of

short fibers and solidification material.

Figure 8 shows the relationships between number of cycles

and double amplitude axial strain. This figure indicates, that the

additional short fibers suppress the deformation to liquefaction.

Additionally, for the case of added solidification material, the

deformation does not advance instantly, even though the

effective stress is close to 0. The deformation reaches high

values at a slow pace.

Figure 9 shows the liquefaction strength curve. The

liquefaction strength for the addition of only short fibers shows

a little strength increase. In contrast to this, significant strength

increase is shown by adding more solidification material.

Figure 10 shows the relationships between additive

conditions

and

liquefaction

strength.

Liquefaction

countermeasures can be created by the addition of certain

solidifying material. Interestingly it is seen that more addition

of short fibers can also reduce the amount of solidification

material. This method may make effective use of waste by

0

C=0%

C=2%

C=1%+B=5%

(u/p

c max

Number of cycles N (cycles)

d

/2

c

'=0.40

d

/2

c

'=0.40

d

/2

c

'=0.20

')

Figure 2. The relationships between number of cycles and max pore

pressure ratio

0

1

2

3

4

5

0 20 40 60 80 100 120

C=0%

C=2%

C=1%+B=5%

DA (%)

Number of cycles N (cycles)

d

/2

c

'=0.20

d

/2

c

'=0.40

d

/2

c

'=0.40

Figure 3. The relationships between number of cycles and double

amplitude axial strain

Table 3. Strength parameter

Additive conditions Cohesion c'

Internal friction angle

φ

'

(%)

(kN/m

2

)

(°)

C = 0

0.0

34.0

C = 0 + F = 1

24.2

40

C =1 + F = 1

64.6

40.5

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

C=0%

C=2%

C=1%+B=5%

Cyclic deviator

stress ratio

/p'

c

Number of cycles N (cycles)

20 34

Figure 4. Liquefaction strength curve

0.1

0.2

0.3

0.4

0.5

0.6

N=20

N=34

Cyclic deviator

stress ratio

/p'

c

Additive conditions

C=0% C=2% C=1%+B=5%

Figure 5. The relationships between additive conditions and

liquefaction strength