1552

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

50mm in diameter and 200mm in height and subjected to a

vertical pressure of 50 kPa. After consolidation, a specimen

measuring 5 cm in diameter and 10 cm in height was formed.

To prepare specimen from samples with an Iwakuni clay

content 17% or less, the soil mixtures were placed in a mold in

5 layers with each layer being compacted using a steel rammer

with a prescribed number of blows. The compaction energy, E

c

,

was calculated as follows (Adachi et al., 2000):

(1)

where, W

R

is the rammer weight (=0.00116 kN), H is the drop

height (m), NL is the number of layers (=5), N

B

is the number

of blows per layer, and V is the volume of mold (m

3

). Various

compaction energies, E

c

, were obtained by changing H and N

B

.

Each soil mixture was thoroughly mixed at an initial water

content of w=11%. Given that the initial water content of a

compacted soil sample does not change the properties of the

clay, the water content was selected to allow the free passage of

carbon dioxide. In order to improve the specimen saturation,

carbon dioxide was first passed through the specimens before

allowing water to percolate.

In this research, soil samples with fines content

F

c

=0, 9.8,

14.7, 16.7% were formed at constant compaction energies,

corresponding to

E

c

=22, 51, 113, 324, 504, 1008 kJ/m

3

, and at

constant relative densities of sand structure, i.e.,

D

r

sc

=0, 30, 50,

65%. (Table.1)Note that for soil samples prepared under

compaction energies of

E

c

=504 and 1008 kJ/m

3

, the variation of

granular void ratios with fines content is practically similar;

therefore, considering the rammer used in the sample

preparation, relative densities of the sand-clay mixtures cannot

be changed even with higher compaction energies. Thus, the

granular void ratios corresponding to these compaction energies

can be considered as the minimum granular void ratios in these

experiments.

As mentioned earlier, for soil samples with fines contents

greater than

F

c

=19.6%, sample preparation by compaction was

not possible; instead, the pre-consolidation method was

employed. Depending on the normal consolidation condition,

the granular void ratio of the pre-consolidated sample is unique

for a given effective confining pressure.

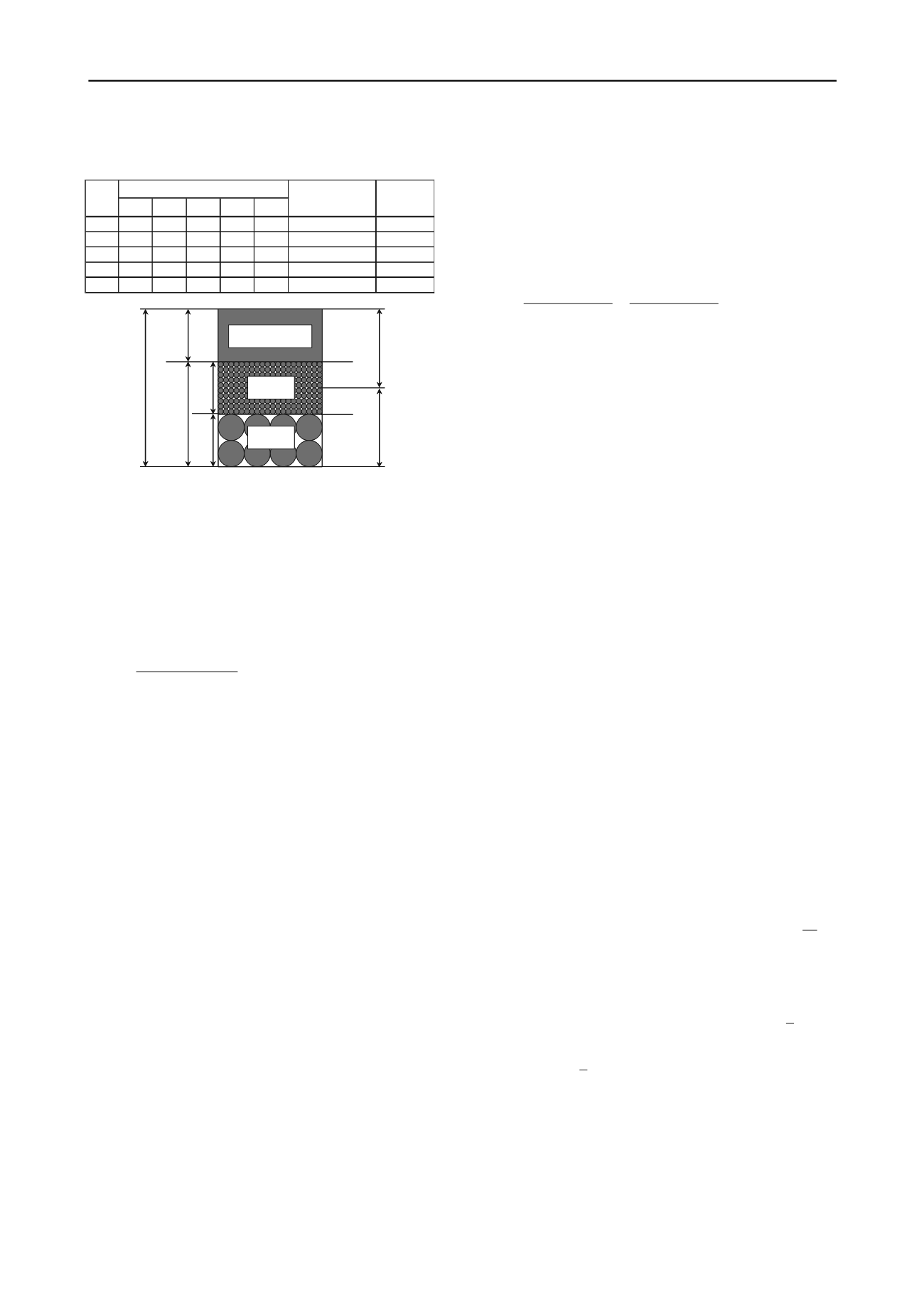

2.3 Skeletal structure of sand-clay mixture

A fully saturated sand-clay mixture has a three-phase

composition, namely the coarse-grained particles, fine-grained

particles and pore water, as shown in Fig. 2. Here,

b

is defined

as the portion of fines that contributes to the active intergrain

contacts. In Thevanayagam et al. (2002), it was introduced to

represent the beneficial secondary cushioning effect of silica

silts in silty sand as follows:

(2)

where

e

ge

is the equivalent granular void ratio,

F

c

is the

fines content (in terms of volume) and b denotes the portion of

the fines that contributes to the active intergrain contacts.

Basically,

b

=0 means that none of the fine grains actively

participates in supporting the coarse-grain skeleton (i.e. the

fines act exactly like voids); and

b

=1 implies that all fines

actively participate in supporting the coarse grain skeleton

(i.e. the fines are indistinguishable from the host sand

particles). The magnitude of

b

depends on grain size disparity

and grain characteristics.

3 UNDRAINED CYCLIC SHEAR PROPERTIES

The specimens of sand-clay soil mixtures prepared by

compaction and pre-consolidation methods were isotropically

consolidated at an effective confining pressure of

c

’=100 kPa.

Then, undrained cyclic triaxial tests were conducted with

effective confining pressure

c

’=100 kPa and loading frequency

f=0.02Hz using an air pressure controlled cyclic triaxial test

apparatus.

Fig. 3 shows the relationship between the cyclic shear

strength ratio (σd/2σc’) required to cause double amplitude

axial strain ε

DA

=5% and the number of cycles (N) for soil

specimens with fines mixtures (Iwakuni clay).

Based on Fig.

3(a), for specimens prepared under high compaction energy

E

c

=504 kJ/m

3

, the liquefaction strength decreases as the fines

content increases, with the liquefaction strength of specimens

with

F

c

=14.7% significantly smaller than those of specimens

with

F

c

=0% and 9.8%. On the other hand, for specimens

prepared under a low compaction energy

E

c

=22 kJ/m

3

(Fig.

3(b)), although the difference between the liquefaction curves of

various samples are small, there is a tendency for the

liquefaction strength to increase with an increase in fines

content.

Next, the results of specimens prepared under constant

fines content

F

c

=0% (Fig. 3(c)) shows that the liquefaction

strength increases as the compaction energy increases, with the

liquefaction strength of specimen with

E

c

=22, 51 kJ/m

3

significantly smaller than those of specimens with

E

c

> 113

kJ/m

3

. On the other hand, for specimens prepared under

constant fines content

F

c

=16.7% (Fig. 3(d)), it is also observed

that there is increase in strength as the compaction energies

increased. However, the liquefaction strengths show almost

similar values.

Fig. 3(e) shows the result of the pre-

consolidation samples for Iwakuni clay mixtures (

F

c

>19.6%).

The cyclic shear strength ratios increase with fines content.

However, in this case the liquefaction strengths show almost

similar values (

F

c

>29.4%).

The cyclic shear strength corresponding to 20 cycles

(hereinafter referred to as cyclic shear strength ratio,

R

L(N=20)

) is

read off from the above curves and plotted against the fines

content for Iwakuni clay mixtures, as shown in Fig. 4.

A

t

constant relative density of sand structure, on the other hand,

any increase in fines content results in an increase in cyclic

strength. This can be explained as follows. In the case of

constant relative density of sand structure, more fines will

occupy the voids between the sand particles when the fines

V

NNHW E

B L

R

c

sf

s

sf

v

sf

v

V

e

sf

ss

eq

b

V

Vb

V

bV V

Vb

V

) 1(

) 1(

) 1(

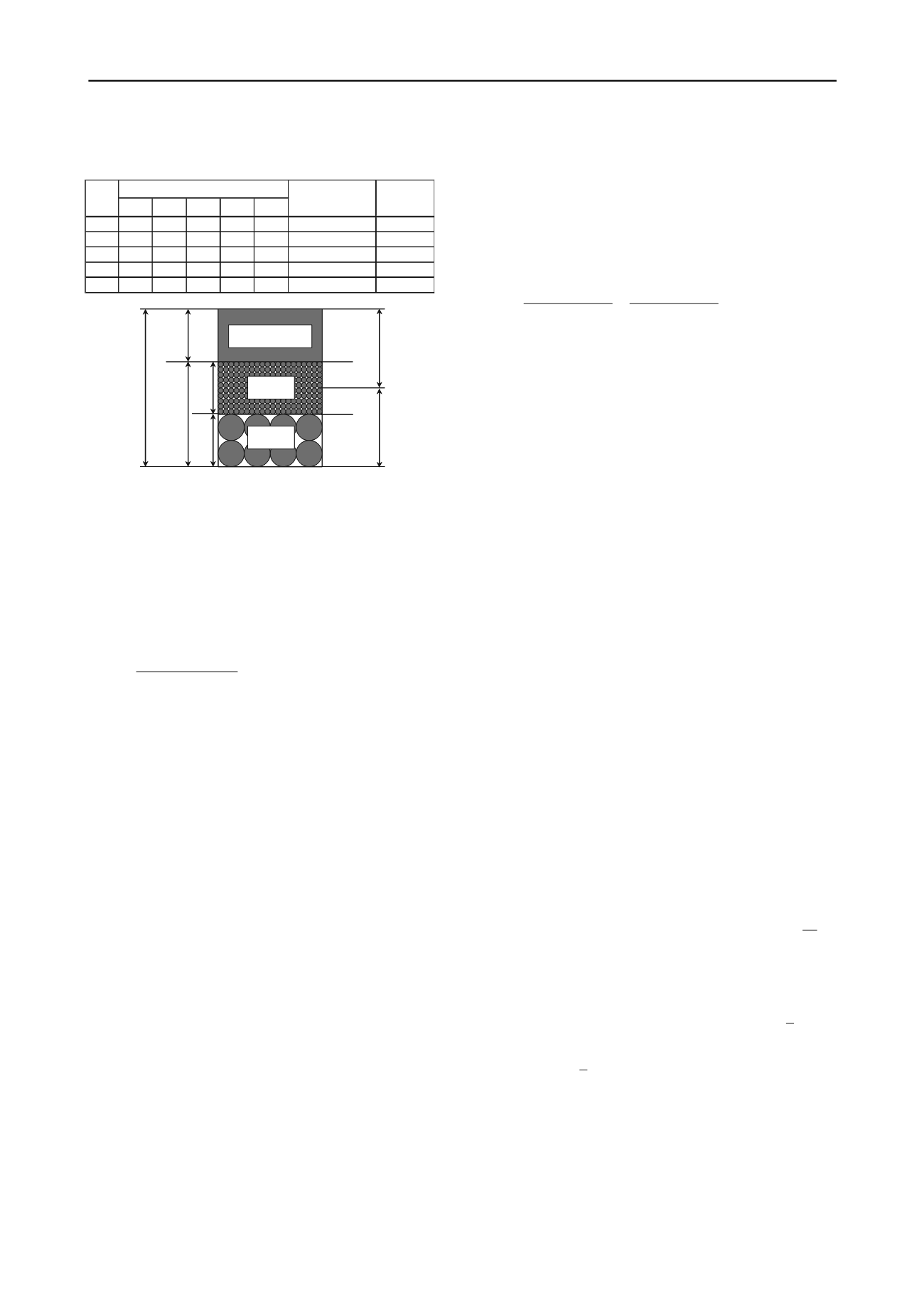

1st

2nd 3rd 4th 5th

504 60 80 100 120 140

0.184

0.00116

324 40 50 65 75 85

0.184

0.00116

113 14 19 23 25 29

0.184

0.00116

51 4 7 10 13 16

0.184

0.00116

22 5 10 15 25 30

0.050

0.00116

Number of dropping per a layer

E

c

(kJ/m

3

)

Height of dropping

weight

(m)

Weight of

rummer

(kN)

Table. 1

Relation between dropping number and

compaction energy

e

ge

V

v

=

e

V

s

=1

V

sf

V

V

ss

(1-

b

)

V

sf

Void

Fines

Sand

1

b

・

V

sf

Fig. 2 Phase diagram