1560

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

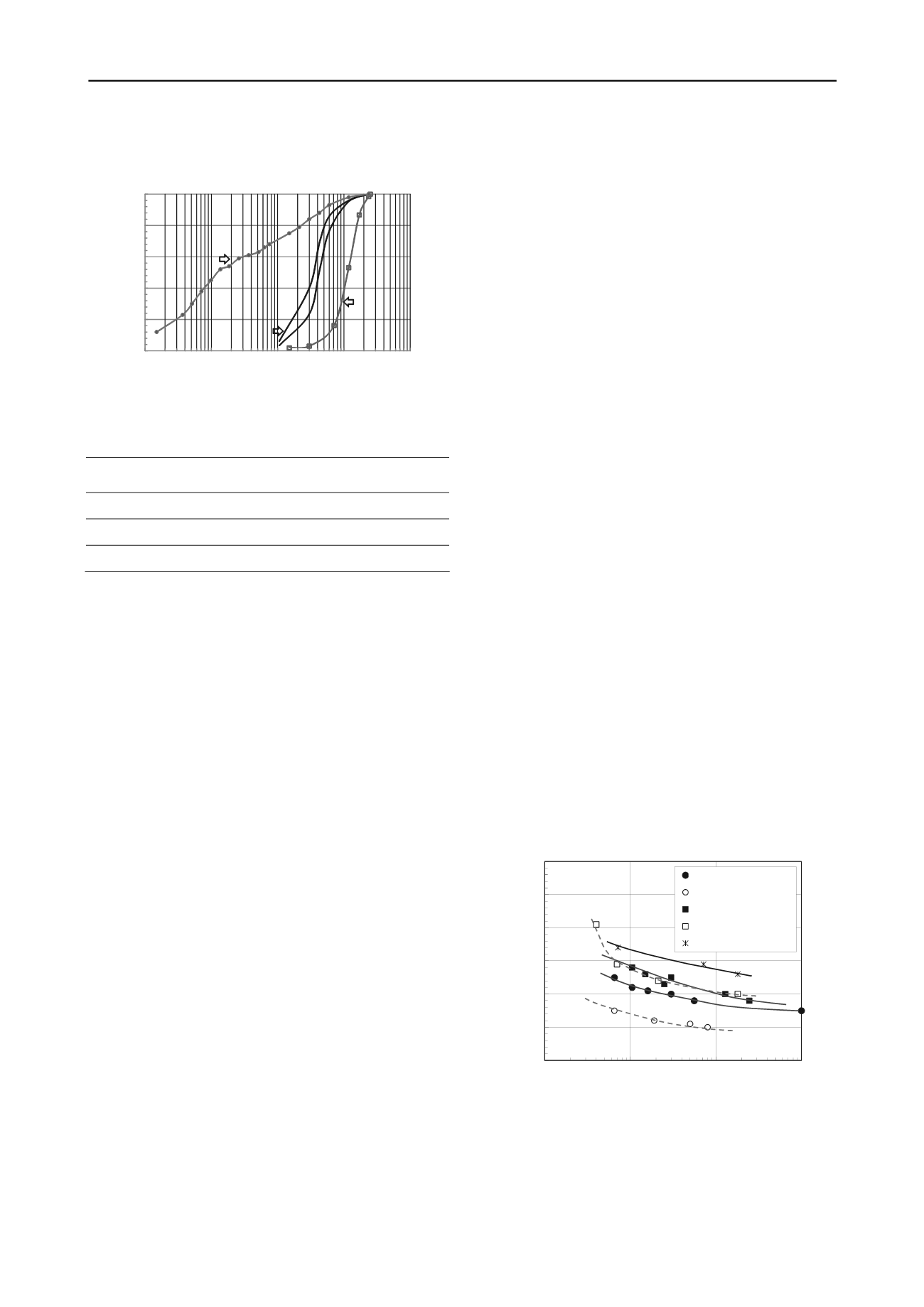

The properties of the tested soils, obtained using methods

based on NZ Standards (1986), are shown in Table 1 and the

grain size distribution curves are shown in Figure 1.

Table 1. Properties of soils used.

Material

Specific

Gravity

Maximum

void ratio

Minimum

void ratio

Carrs Rd

2.52

N/A

*

N/A

*

Mikkelsen Rd

2.49

1.165

0.717

Pumice sand

1.95

2.584

1.760

*Not applicable since sample has very high fines content

3

EXPERIMENTAL METHOD

3.1

Undrained cyclic triaxial tests

The undisturbed soil samples obtained from the site using

60mm push tubes were carefully transported to the laboratory.

In case the soil sample was deemed stable, they were extracted

from the tube using hydraulic jack. In some cases, the soil

sample was deemed loose and extracting them straight away

will destroy the structure and fabric; this was noted in the soil

samples taken from shallow depths (3 m and 6 m) at Mikkelsen

Rd site. In these cases, the tubes with the soil sample inside

were placed in a freezer for 1-2 days. Then, the frozen specimen

was extruded from the sampling tube. Trimming was carried out

at the two ends of the specimens for the preparation of square

ends. The height of the specimen used was 120mm for the Carrs

Rd samples, and 100mm for Mikkelsen Rd samples (due to

sample unavailability). Filter papers were placed at the ends to

prevent clogging of the porous discs. The specimen was placed

inside a rubber membrane and, for frozen specimens, they were

allowed to thaw prior to testing. Saturation of the specimen was

ensured by allowing water to enter the specimen by increasing

the back pressure. B-value check was carried out to confirm that

fully saturated condition had been achieved. Specimens were

then isotropically consolidated at the target effective confining

pressure,

c

’.

For the reconstituted specimens, it was not easy to

completely saturate the pumice sand because of the presence of

voids from the surface to the particle interior. For this purpose,

saturated specimens were made using de-aired pumice sands,

i.e., sands were first boiled in water to remove the entrapped air.

To prepare the test specimens, the sand was water-pluviated into

a two-part split mould which was then gently tapped until the

target relative density was achieved. Next, the specimens were

saturated with appropriate back pressure and then isotropically

consolidated at the target effective confining pressure,

c

’. B-

values > 0.95 were obtained for all specimens. The test

specimens were 75mm in diameter and 150mm high.

The cyclic loading in the tests were applied by a hydraulic-

powered loading frame from Material Testing Systems (MTS).

A sinusoidal cyclic axial load was applied in the tests at a

frequency of 0.1Hz under undrained condition. In addition to

the axial load, the cell pressure, pore pressure, volume change

and axial displacement were all monitored electronically and

these data were recorded via a data acquisition system onto a

computer for later analysis.

0

20

40

60

80

100

0.001

0.01

0.1

1

10

Percent finerby

w

eight (%

)

Grain size (mm)

Carrs Rd

sample

Mikkelsen Rd

sample

Pumice

Figure 1. Grain size distribution curves of soils used in the tests.

3.2

Field tests

In this paper, the results of two sets of field tests are discussed:

cone penetration testing (CPT) and seismic dilatometer testing

(sDMT). These tests were performed near the two sites where

the undisturbed soil samples were obtained. The CPT was

performed every 100mm depth interval, while the sDMT was

carried out at every 500mm interval, with the first reading taken

at 1m depth from the ground surface. An electrically-operated

Autoseis hammer was used to generate a shear wave that

propagated through the ground. The shear wave signals were

recorded by the geophones in the seismic module and were sent

back to a computer system as seismographs for analysis

purposes. The seismographs from both geophones were shown

as similar waves but with the time lag due to the fact that one of

the geophones is 500 mm deeper than the other. A computer

program allowed the two seismographs to be re-phased and so

that the actual travel time difference of the shear wave could be

calculated. The shear wave velocity of the soil layer between

the two geophones was calculated from the interval between the

two geophones divided by the difference in travel time.

4 TEST RESULTS AND DISCUSSION

4.1

Effect of density on reconstituted pumice specimens

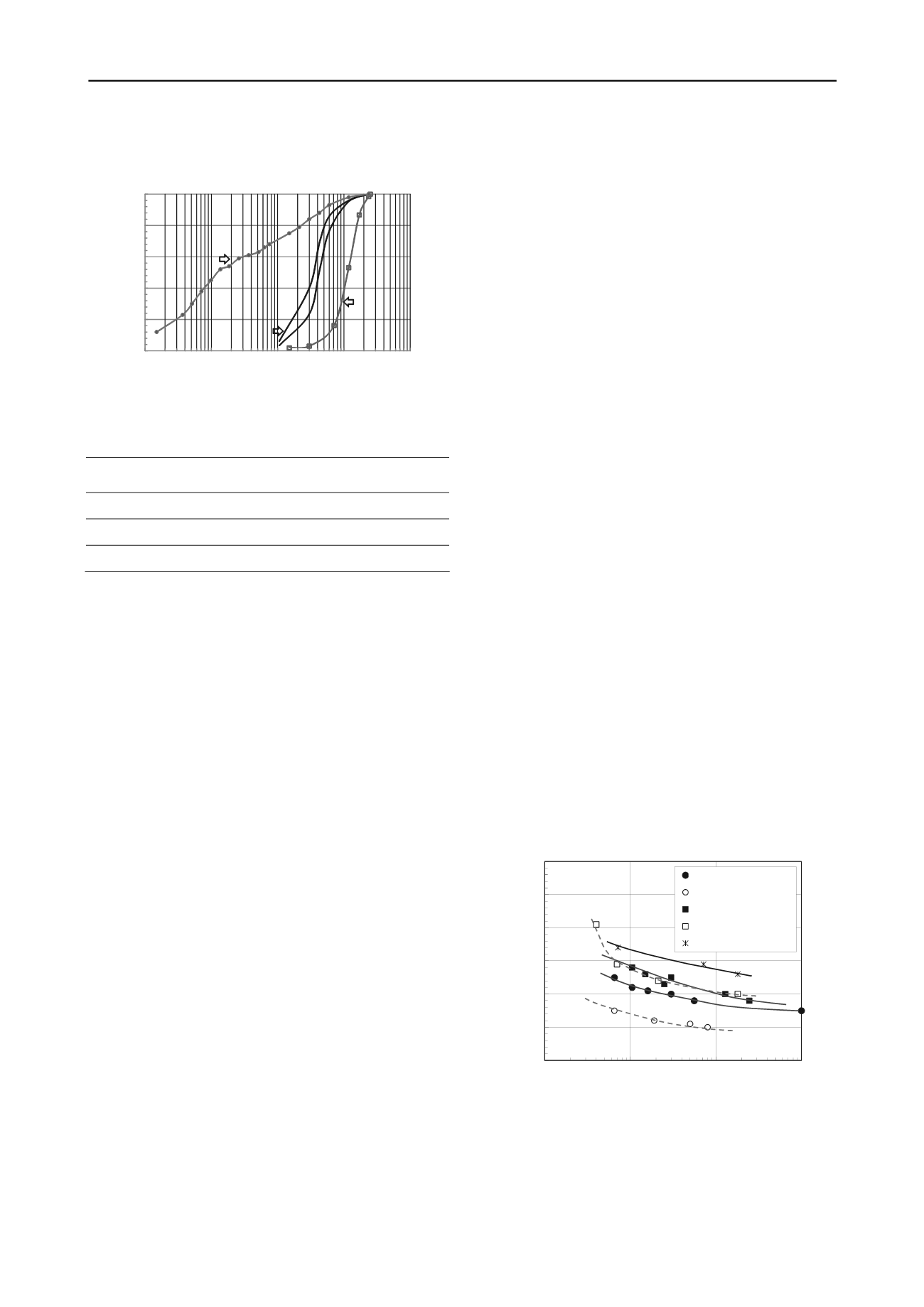

Orense et al. (2012) discussed the effects of relative density on

the liquefaction resistance of reconstituted pumice sands. The

curves for dense pumice specimen (

D

r

=70%), loose pumice

specimen (

D

r

=25%), as well as for the undisturbed Mikkelsen

Rd sample obtained (at 6.0-6.6m), corresponding to double

amplitude axial strain

DA

=5% are reproduced in Figure 2. The

slope of the curve for loose sand is gentle when compared to

that of dense sand, with the latter having higher cyclic

resistance. On the other hand, the slope of the curve for

undisturbed sample is as gentle as the loose reconstituted

samples, but the CSR (=

d

/2

c

’, where

d

is the deviator stress)

is about three times higher.

0

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

Cyclic Shear Stress Ratio, CSR

Number of cycles, N

Pumice (Dr=25%)

Toyoura (Dr=50%)

Pumice (Dr=80%)

Toyoura (Dr=90%)

Undisturbed sample

Pumice (

D

r

=25%)

r

ice (

r

7

r

ndisturbed s le

Cyclic shear stress ratio,

d

/2

c

’

Nu ber of cycles,

N

Figure 2. Cyclic resistance curves for the samples used.

Also plotted in the figure are the cyclic resistance curves for

loose (

D

r

=50%) and dense (

D

r

=90%) Toyoura sand, as reported

by Yamamoto et al. (2009). Comparing the curves for Toyoura

sand and for reconstituted pumice sands, two things are clear:

(1) loose specimens have gentle cyclic resistance curves, while