1561

Technical Committee 203 /

Comité technique 203

dense specimens have curves rising sharply as the number of

cycles decreases; and (2) while the effect of relative density is

very pronounced for Toyoura sand, the effect of relative density

on pumice specimens appear to be not as remarkable.

4.2

Effect of confining pressure

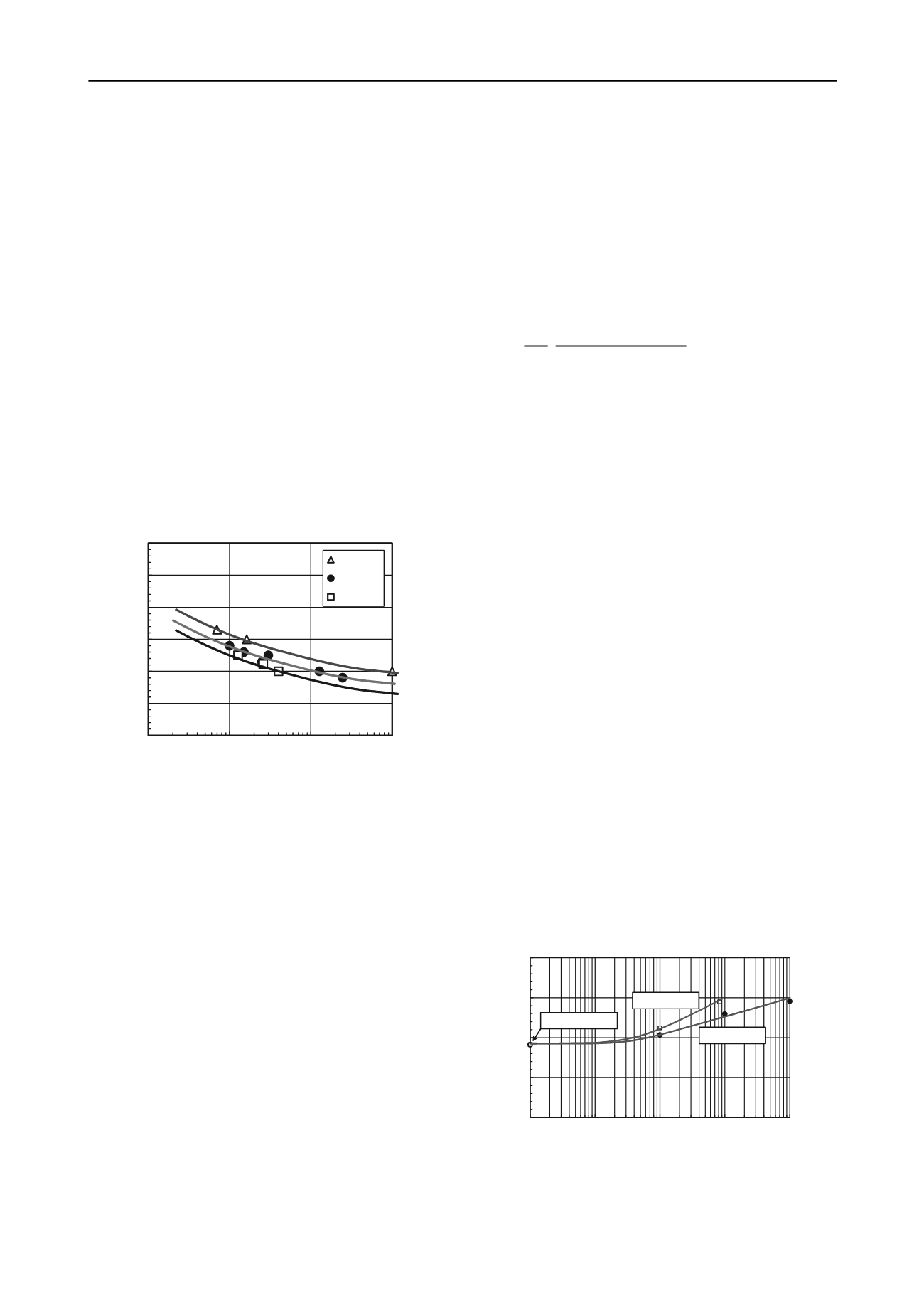

Next, the influence of effective confining pressure on the

liquefaction resistance of reconstituted pumice sands was

investigated. For this purpose, dense pumice sand specimens

(initial void ratio,

e

i

=1.90-2.00) were subjected to three different

levels of effective confining pressure,

c

’=35, 100 and 500 kPa

under different levels of cyclic shear stress ratio, CSR

(=

d

/2

c

’). Figure 3 illustrates the confining pressure

dependency of liquefaction resistance for reconstituted pumice.

It can be seen that the curves are almost parallel to each other,

with the liquefaction resistance increasing as the confining

pressure decreases, consistent with the observations made on

natural sands (e.g., Rollins and Seed, 1988). The value of the

correction factor for overburden stress

K

(CSR causing

DA

=5% in 15 cycles under any confining pressure normalised

to the corresponding value of CSR at

c

’=100 kPa) is equal to

1.16 for

c

’=35 kPa and 0.88 for

c

’=500 kPa. These values

appear to coincide with those reported for reconstituted natural

sands (e.g., Boulanger and Idriss, 2004).

4.3

Development of particle crushing during cyclic loading

The level of particle crushing during undrained cyclic testing

has been reported by Orense et al. (2012). They noted that under

the confining pressures considered, pumice undergoes

remarkable particle crushing when subjected to cyclic shear. As

cyclic shearing and particle crushing occur, the soil structure is

gradually stabilized, resulting in higher cyclic shear resistance,

even exceeding that of Toyoura sand. The cyclic shearing and

the associated particle breakage resulted in stable soil structure

for both dense and loose cases, and therefore, the effect of

density was not as remarkable when compared to the cyclic

behaviour of Toyoura sand, a hard-grained sand.

To elucidate further the development of particle crushing

during a cyclic loading, a series of tests were performed such

that the tests were terminated after a specified number of cycles

afterwhich sieve analyses were performed. For these tests,

virgin samples were used at each test. A confining pressure of

c

’=100 kPa was considered, with the void ratio set at

e

i

=1.90-

2.00. For CSR=0.10, the sieve analyses were carried out: (1) on

the virgin samples; (2) after the end of consolidation stage; (3)

after

N

=10 cycles; (4) after

N

=100 cycles; and (5) after

N

=1000

cycles. On the other hand, for CSR=0.20, sieving was done (1)

after

N

=10 cycles; and (2) after

N

=83 cycles where initial

liquefaction (pore pressure ratio,

r

u

=100%) occurred.

The grain size distributions of the specimens after the tests

were determined. Particle crushing occurred, but with the level

of CSR and the number of cycles applied, it was difficult to use

the grading curves to make reasonable comparison. Instead, a

method of evaluating particle crushing originally proposed by

Miura and Yamanouchi (1971) was used which involves the

quantification of the surface area of the particles. The specific

surface of the particles was measured by first sieving the soil

using 2.5 mm, 2.0 mm, 1.18 mm, 0.5 mm, 0.212 mm, 0.15 mm

and 0.063 mm sieve sizes. For this range of particle sizes, the

specific surface area (in mm

2

/mm

3

) is calculated as:

d

ws

m

m

G d

d

F S

3

2

2/

3/4

2/

4

100

(1)

where

d

m

=(

d

1

.

d

2

)

0.5

,

d

1

and

d

2

are adjacent sieve sizes (e.g.,

0.50mm and 0.212 mm),

F

is the % by weight retained on the

sieve,

G

s

is the specific gravity of the particles,

w

is the unit

weight of water and

d

is the dry unit weight of the specimen.

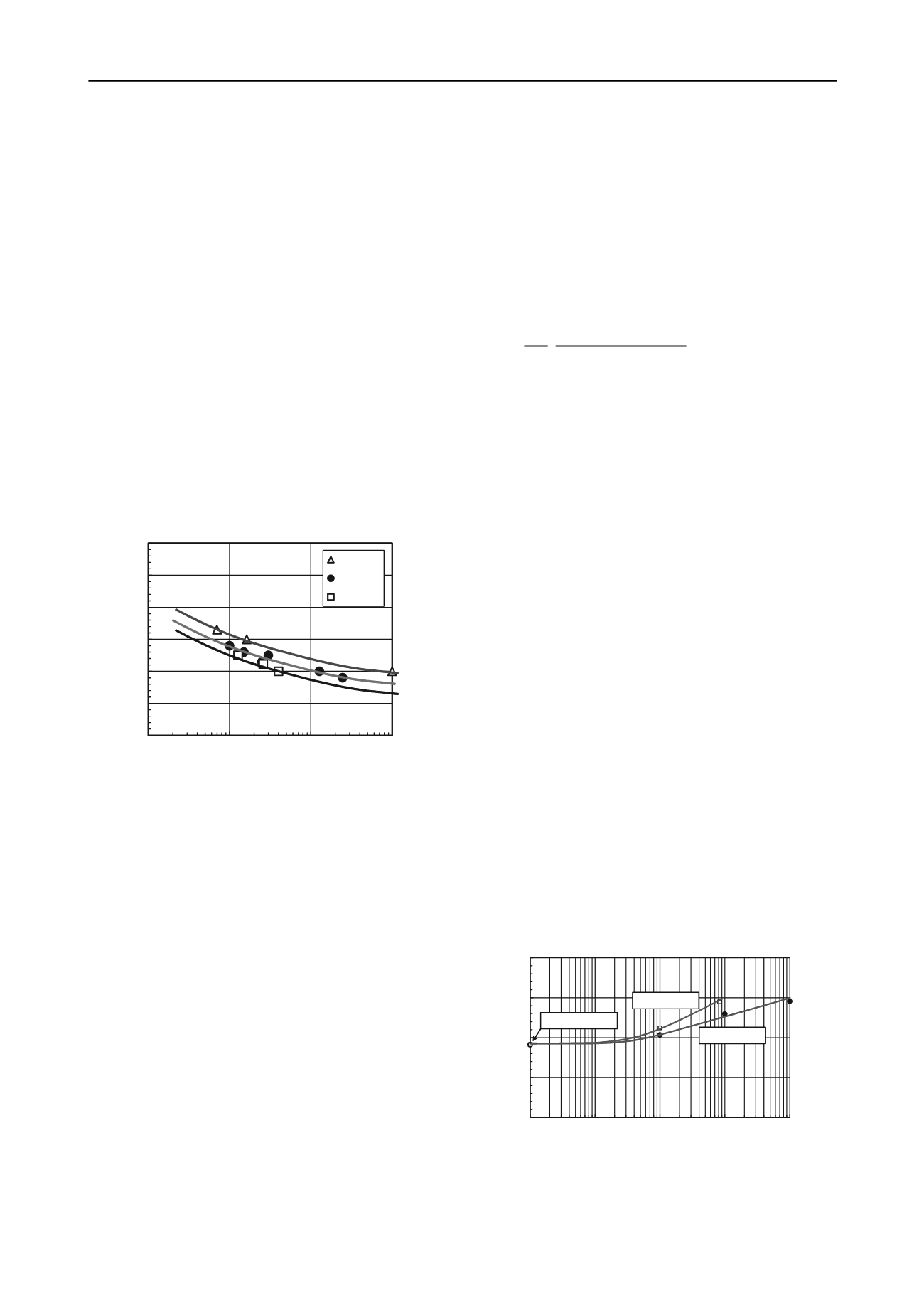

Figure 4 shows the development of the surface area

S

for the

different tests described above. Firstly, it was observed that

consolidation at 100 kPa effective confining pressure did not

induce appreciable particle breakage to the pumice particles;

however, the cyclic shearing did. Secondly, the degree of

particle crushing increased with the amplitude of applied CSR.

For the test with CSR=0.20, the increase in surface area during

the initial stage of cyclic loading was small; however, as the

liquefaction stage was reached (

N

=83), the surface area

increased remarkably because large strains occurred with

associated translation and rotation of particles causing the

higher degree of crushing. For CSR=0.10, the state of

liquefaction did not occur even when

N

=1000 cycles. Particle

breakage was more or less gradual, with almost linear variation

with the logarithm of

N.

4.4

Comparison between laboratory and field data

Cone penetration tests (CPT) and seismic dilatometer tests

(sDMT) were performed at the Mikkelsen Rd site and Carrs Rd

site to supplement the undrained cyclic triaxial tests conducted

on the undisturbed samples taken from these sites. The field

tests were performed as near as possible to the sampling site.

Correlations between the cyclic resistance obtained from the

laboratory tests and the in-situ parameters were performed to

confirm which method was appropriate for pumice. Note that

undisturbed soil samples were obtained at three elevations at

Mikkelsen Rd site, while samples from Carrs Rd site were taken

only at a single depth; hence, emphasis is placed on the former.

In addition, the results presented herein may be appropriate only

for the two sites investigated and further tests are necessary to

confirm their applicability to other pumiceous sites.

0

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

C

yclic

S

hearS

tress

R

atio,C

S

R

Number of cycles, N

35 kPa

100 kPa

500 kPa

Figure 3: Comparison of liquefaction resistance curves for reconstituted

dense pumice sands under different

c

’

.

In the comparison, the liquefaction resistance of the

undisturbed samples is specified in terms of the magnitude of

80

85

90

95

100

0

1

10

100

1000

S

urface

area,S

(m

m

2

/m

m

3

)

No. of cycles, N

�

d

/2

�

c

’=0.20

�

d

/2

�

c

’=0.10

Consolidation

Figure 4. Relationships between specific surface area and number of

cycles during cyclic undrained tests.