1553

Technical Committee 203 /

Comité technique 203

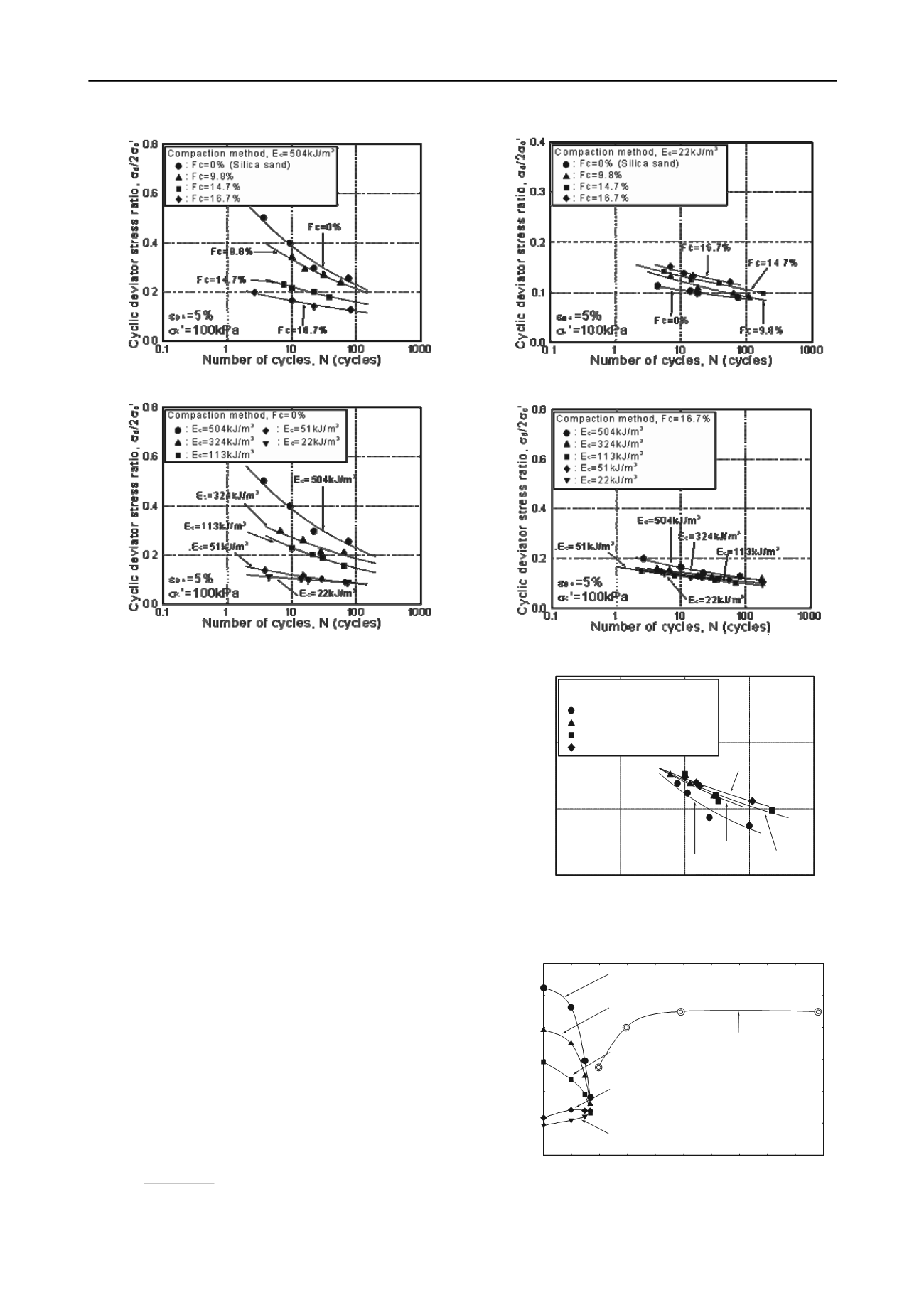

(a)

E

c

=504kJ/m

3

(at constant compaction energy)

(b)

E

c

=22kJ/m

3

(at constant compaction energy)

(d)

F

c

=16.7% (at constant fines content)

(c)

F

c

=0% (at constant fines content)

0.1

1

10

100

1000

0.0

0.2

0.4

0.6

content is high, resulting in an increase in density of the

specimen leading to an increase in cyclic strength.

4 RELATIONSHIP BETWEEN SKELETAL STRUCTURE

AND CYCLIC SHEAR STRENGTH

Based on the results of the cyclic shear tests discussed above, it

can be summarised that the fines content and the resulting

skeletal structure have significant effects on the cyclic strength

of clay-sand mixtures. By assigning different values of b, the

void ratios are re-calculated. From the results, a

b

value of 0.3

indicates that almost all the data falls into a narrow band that

surrounds the data for clean sand (

F

c

=0%), as illustrated in Fig.

5. This observation suggests that for

F

c

<20%, the effect of fines

on the cyclic shear strength is about 30% of that of sand for

Iwakuni clay.

5 EVALUATION OF LIQUEFACTION RESISTANCE BY

EQUIVALENT GRANULAR VOID RATIO

It is widely known that soil density has significant effects on the

engineering properties of sandy soils. Due to the effects of the

size and shape of soil particles and uniformity, however, the

compactness of sandy soils can not be evaluated reasonably

only by the in-site dry density. Relative density is computed

from the maximum and minimum void ratios (dry densities) and

in-site void ratio (dry density). The maximum and minimum dry

void ratio are determined according to a standardized method

(for example, ASTM D4253 and D4254, JIS A 1224). However,

it can only be applied to a small fine (

F

c

<5%) sandy soil. In Fig.

6, the relationship between equivalent granular relative density

and

R

L(N=20)

was illustrated for all the soil mixtures used. The

equivalent granular relative density

D

rge

, is defined as:

(4)

Fig. 3.

Cyclic shear strength curves

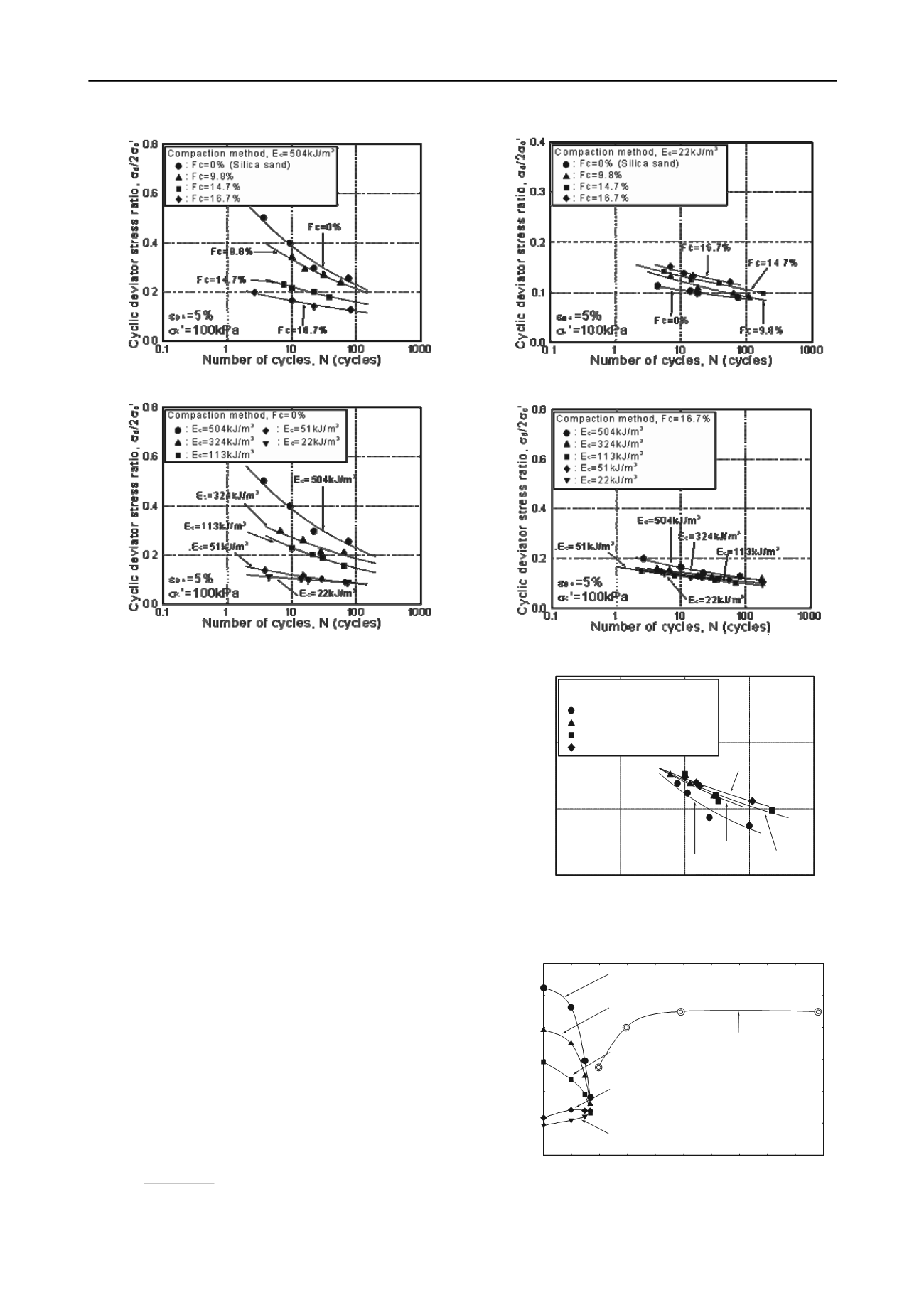

Fig. 4

Correspond to constant compaction energy and pre-

consolidation specimens

(e)

F

c

=19.6~98.0% (pre-consolidation specimen)

Cyclic deviator stress ratio,

d

/2

c

'

Number of cycles, N (cycles)

DA

=5%

c

'=100kPa

Pre-consolidation method

Vertical stress,

v

=50kPa

: Fc=19.6%

: Fc=29.4%

: Fc=49.0%

: Fc=98.0% (Iwakuni Clay)

Fc=19.6%

Fc=29.4%

Fc=49.0%

Fc=98.0%

0 10 20 30 40 50 60 70 80 90 100

0.05

0.10

0.15

0.20

0.25

0.30

0.35

Cyclic deviator stress ratio, R

L(N=20)

Fines content, Fc(%)

E

c

=504kJ/m

3

E

c

=324kJ/m

3

E

c

=113kJ/m

3

E

c

=51kJ/m

3

E

c

=22kJ/m

3

Pre-consolidation

method(

σ

v

=50kPa)

(%)

0

in

D

10

m

max

max

g

g

ge

g

rge

e

e

e

e