1550

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

utilization of recycled Bassanite has been verified. In the

future, it is important to study the suppression technique for

a variety of earthquakes, focusing attention on not only

suppression of liquefaction, but also recycling costs.

recycling of waste wood from earthquake damage and bamboo

chips.

4. CONCLUSIONS

(1) The liquefaction resistance is increased, due to the increase

of cohesion from the added solidification material. For the

added solidification material, the interparticles forces of

sand due to this cohesion suppresses liquefaction. The

magnitude of the suppression effect of liquefaction is

influenced by the interparticles forces of the sand.

5. ACKNOWLEDGEMENTS

The study presented in this paper was supported by Professor

Timothy A. Newson (University of Western Ontario) and Dr.

Takuro Fujikawa. This support is gratefully acknowledged.

(2) The effect of shear deformation suppression also increases

due to the development of apparent cohesion. For the case

of short fiber and solidification material, liquefaction is

suppressed by the cohesion of solidification material and

shear deformation suppression.

6. REFERENCES

(3) It is considered from the study results that, the utilization of

discharged wood waste by the earthquake will have a

similar effect as the effect of shear deformation suppression

Yasuda S. 2011. The liquefaction damage of KANTO. Board of

Tohoku-Pacific Ocean Earthquake disaster investigation report (in

Japanese).

Sasaki T. 2012. River bank and liquefaction. Public Works Research

Institute,

/

of the short fibers. Additionally, the effectiveness of the

Zen K. 1994. Remedial Measures for Reclaimed Land by Premixing

Method.

The Japanese Society of Soil Mechanics and Foundation

Engineering

, Vol.42, No.2, 37-42 (in Japanese).

0

0.2

0.4

0.6

1

0.8

Sezaki M. 2011. Liquefaction and slope failures in the Great East Japan

Earthquake.

Text of road technology workshops

(in Japanese).

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

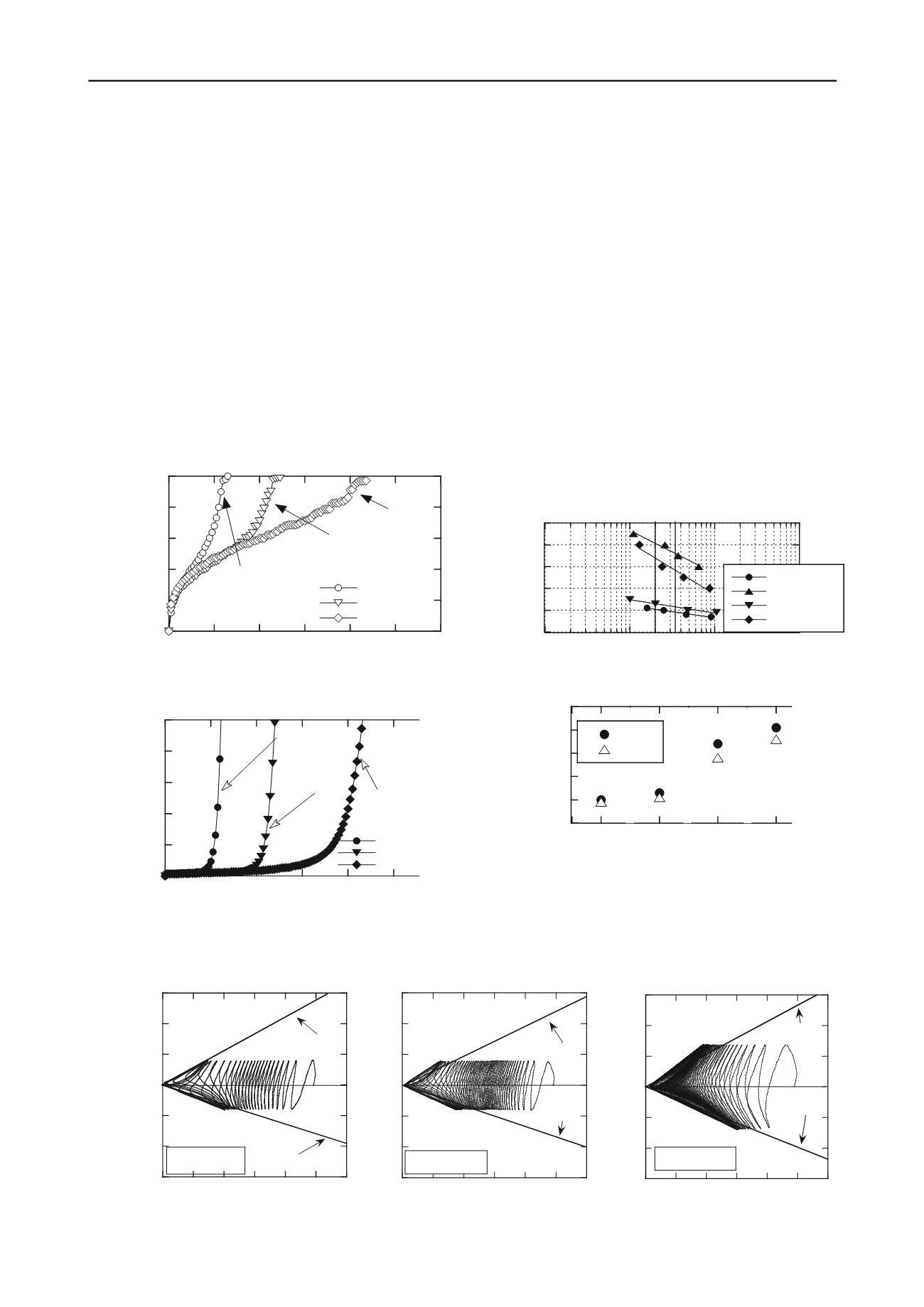

Toyoura Sand

C=0%

p'

c

0.20

d

=1.486(g/cm

3

)

PT Line

PT Line

(a) C=0%

Figure 6. Effective stress path diagram

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%+F=1%

d

=1.489(g/cm

3

)

p'

c

PT Line

PT Line

(b) C=0%+F=1%

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura

C=1%+F=1%

P'

c

d

=1.481(g/cm

3

)

PT Line

PT Line

(c) C=1%+F=1%

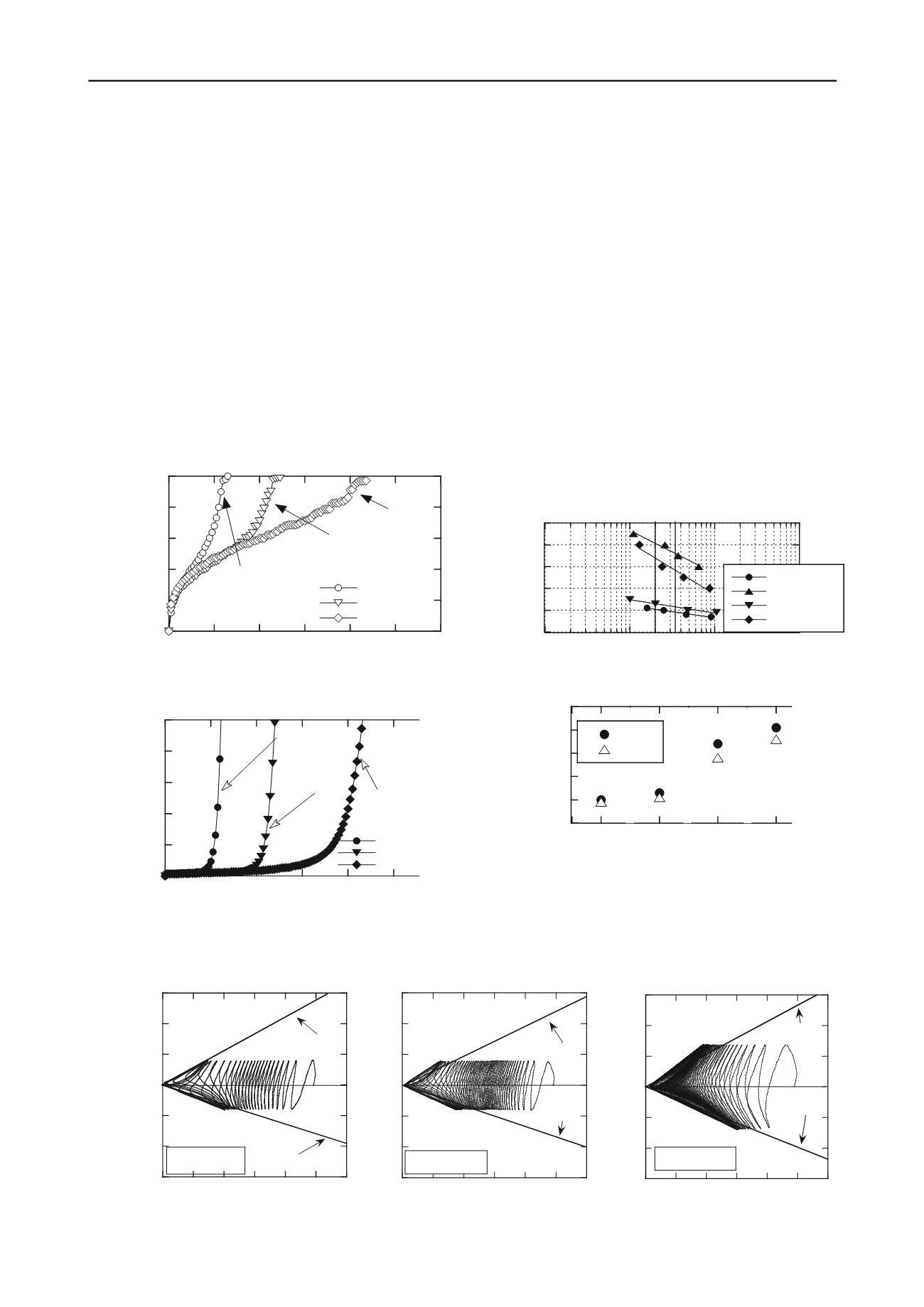

0 20 40 60 80 100 120

C=0%

C=0%+F=1%

C=1%+F=1%

(u/p

c

')

max

Number of cycles N (cycles)

d

/2

c

'=0.35

d

/2

c

'=0.20

d

/2

c

'=0.20

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

C=0%

C=2%

C=0%+F=1%

C=1%+F=1%

Cyclic deviator

stress ratio

/p'

c

Number of cycles N (cycles)

DA=5%

Figure 7. The relationships between number of cycles and max pore

pressure ratio

0

1

2

3

4

5

0 20 40 60 80 100 12

Figure 9. Liquefaction strength curve

0.1

0.2

0.3

0.4

0.5

0.6

N=20

N=34

Cyclic deviator

stress ratio

/p'

c

Additive conditions

C=0%

C=2%

C=1%

+F=1%

C=0%

+F=1%

0

C=0%

C=0%+F=1%

C=1%+F=1%

DA (%)

Number of cycles N (cycles)

d

/2

c

'=0.20

d

/2

c

'=0.35

d

/2

c

'=0.20

Figure 10. The relationships between additive conditions and

liquefaction strength

Figure 8. The relationships between number of cycles and double

amplitude axial strain

recycling of waste wood from earthquake damage and

bamboo

chips.

4. CONCLUSIONS

(1) The liquefaction resistance is increased, due to the

increase of cohesion from the added solidification

material. For the added solidification material, the

interparticles fo ces of sand due to this cohesion

suppr ses liquefaction. The m gnitude of the

suppression effect of liquefaction is influenced by the

i terparticles forces of the sand.

(2) The eff ct of shear deformation suppression lso

incr as s due to the development of apparent

cohesion. For the cas f short fiber and solidification

material, liqu faction is suppressed by the cohesion of

solidification material and shear deformation

su pre sion.

(3) It is considered from the study results that, the

utilization of disc arged wood w ste by the

earthquake will have a similar effec as the effect of

shear de orm tion suppression

of the short fibers. Additionally, the effectiveness of

the

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%

p'

c

0.20

d

=1.486(g/cm

3

)

PT Line

PT Line

(a) C=0%

Figure 6. Effective stress path diagram

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%+F=1

d

=1.489(g/cm

3

)

p'

c

PT Line

PT Line

(b) C=0%+F=1%

-150

-100

-50

0

50

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura

C=1%+F=1%

P'

c

d

=1.481(g/cm

3

)

PT Line

PT Line

(c) C=1%+F=1%

0

0.2

0.4

0.6

0.8

1

0 20 40 60 80 100 120

C=0%

C=0%+F=1%

C=1%+F=1%

(u/p

c

')

max

Number of cycles N (cycles)

d

/2

c

'=0.35

d

/2

c

' 0.20

d

/2

c

'=0.20

Figure 7. The relationships between number of cycles and max pore

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

C=0%

C=2%

C=0%+F=1%

C=1%+F=1%

Cyclic deviator

stress ratio

/p'

c

Number of cycles N (cycles)

DA=5%

pressure ratio

Figure 9. Liquefaction strength curve

0

1

2

3

4

5

0 20 40 60 80 100

C=0%

C=0%+F

C=1%+F

DA (%)

Number of cycles N (cycles)

d

/2

c

'=0.20

d

/2

c

'=0.35

d

/2

c

'=0.20

0.1

0.2

0.3

0.4

0.5

0.6

N=20

N=34

Cyclic deviator

stress ratio

/p'

c

Additive conditions

C=0%

C=2%

C=1%

+F=1%

C=0%

+F=1%

Figure 8. The relationships between number of cycles and

double amplitude axial strain

Figure 10. The relationships between additive conditions and

liquefaction strength

recycling of waste wood from earthqu ke damage a d

bamboo

chips.

4. CONCLUSIONS

(1) The liquefac ion resistance is increased, due to the

increase of cohe io from the ad ed solidification

mat rial. F r the adde li i i ti aterial, the

interparticl s f rces of sand due to this cohesion

suppr sses liquefaction. The magnitud of the

suppression effect of liquefac on is influenced by the

interparticles forc s of the sand.

(2) The effect of shear def mation suppress on also

inc e ses due t the development f appar nt

cohesion. For the case of short fiber and solidificati

mat rial, liquefacti n is suppresse by the cohesion of

solidi icat on material and sh ar deformation

uppression.

(3) It is considered from the study results that, the

utilization of discharged wood waste by the

earthquake will have a similar ef ct as he effect of

shear deformation suppression

of the short fibers. Additionally, the effectiveness of

the

-150

-1 0

-50

0

50

1 0

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

ffective mean principal stress p' (kPa)

Toyoura Sand

C=0%

p'

c

0.20

d

=1.486(g/cm

3

)

PT Line

PT Line

(a) C=0%

Figure 6. Effective stress path diagram

-150

-1 0

-50

0

50

100

150

0 20 4 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%+F=1%

d

=1.489(g/cm

3

)

p'

c

PT Line

PT Line

(b) C=0%+F=1%

-150

-1 0

-50

0

50

1 0

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura

C=1%+F=1%

P'

c

d

=1.481(g/cm

3

)

PT Line

PT Line

(c) C=1%+F=1%

0

.2

0.4

0.6

0.8

1

0 20 40 60 80 100 120

C=0%

C=0%+F=1%

C=1%+F=1%

(u/p

c

')

max

Number of cycles N (cycles)

d

/2

c

'=0.35

d

/2

c

'=0.20

d

/2

c

'=0.20

Figure 7. The relationships between number of cycles and max pore

0.1

0.2

0.3

0.4

0.5

0.6

1

10

100

1000

C=0%

C=2%

C=0%+F=1%

C=1%+F=1%

Cyclic deviator

stress ratio

/p'

c

Number of cycles N (cycles)

DA=5%

pressure ratio

Figure 9. Liquefaction strength curve

0

1

2

3

4

5

0 20 40 60 80 100

C=0%

C=0%+F

C=1%+F

DA (%)

Number of cycles N (cycles)

d

/2

c

'=0.20

d

/2

c

'=0.35

d

/2

c

'=0.20

0.1

0.2

0.3

0.4

0.5

0.6

N=20

N 34

Cyclic deviator

stress ratio

/p'

c

Additive conditions

C=0%

C=2%

C=1%

+F=1%

C=0%

+F=1%

Figure 8. The relationships between number of cycles and

double amplitude axial strain

Figure 10. The relationships between additive conditions and

liquefaction strength

recycling of waste wood from earthquake damage and

bamboo

chips.

4. CONCLUSIONS

(1) The liquefaction resistanc is increased, due to the

increase of cohesion from the added solidification

material. For the added solidification material, the

interparticles f rces of sand due to this cohesion

suppr sses liquefaction. Th m gnitude of the

suppression e fect of liquefact on is influenced by the

inter art c es f ces of the sand.

(2) The ffec of shear deformation suppr ssion also

incr ases due to t e develo m nt of apparent

cohes on. For the case of sh t fib r and solid fication

materi l, liquefact n is suppressed by the cohesion of

solidification m teri l and

hear deformation

suppression.

(3) It is considered from the study results that, the

utilization of dis harged wood was e by the

earthquake will have a similar effect as the ef ect of

shear def rmation suppression

of the short fibers. Additiona ly, h eff ctiveness of

the

-150

-100

-50

0

5

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%

p'

c

0.20

d

=1.486(g/cm

3

)

PT Line

PT Line

(a) C=0%

Figure 6. ff ctive str ss path diagram

-15

-100

-50

0

5

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura Sand

C=0%+F=1%

d

=1.489(g/cm

3

)

p'

c

PT Line

PT Line

(b) C= %+F=1%

-15

-100

-50

0

5

100

150

0 20 40 60 80 100 120

Deviator stress q (kPa)

Effective mean principal stress p' (kPa)

Toyoura

C=1%+F=1%

P'

c

d

=1.481(g/cm

3

)

PT Line

PT Line

(c) C=1%+F=1%

0

0.2

0.4

0.6

0.8

1

0 20 40 60 80 100 120

C=0%

C=0%+F=1%

C=1%+F=1%

(u/p

c

')

max

Number of cycles N ( ycles)

d

/

c

'=0.35

d

/2

c

'=0.20

d

/2

c

'=0.20

Figure 7. The relationships between number of cycles and max pore

0.1

2

3

4

0 5

0.6

1

10

100

10 0

C=0%

C=2%

C=0%+F=1%

C=1%+F=1%

Cyclic deviator

stress ratio

/p'

c

Number of cycles N (cycles)

DA=5%

pressure ratio

Figure 9. Liquefaction strength curve

0

1

2

3

4

5

0 20 40 60 80 100

0

C=0%+F

C=1%+F

DA (%)

Number of cycles N (cycl )

d

/2

c

'=0.20

d

/2

c

'=0.35

d

/2

c

'=0.20

0.1

0.2

0.3

.4

0.5

.6

N=20

N=34

Cyclic deviator

stre s ratio

/p'

c

Additive conditions

C=0%

C=2%

C=1%

+F=1%

C=0%

+F=1%

Figure 8. The relationships between number of cycles and

double amplitude axial strain

Figure 10. The relationships between additive conditions and

liquefaction strength