1562

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

CSR required to produce

DA

=5% in 15 cycles of uniform load

application; herein, this is referred to as (

CRR

)

triaxial

. The

conditions the laboratory specimens were subjected to were

different from those in-situ and corrections need to be applied to

the laboratory-obtained values before comparing with the in-situ

liquefaction resistance, (

CRR

)

field

. Due to space constraints,

these corrections are not presented in detail here; suffice it to

say that the following corrections were incorporated: (1)

correction due to difference in consolidation stress,

C

1

; (2)

correction due to sample disturbance,

C

3

; (3) correction due to

densification during handling,

C

4

; and (4) correction due to

loading direction,

C

5

. Moreover, all results are expressed in

terms of

c

’=100 kPa using

K

interpolated from Figure 3.

5 CONCLUSIONS

In order to investigate the liquefaction characteristics of pumice

sands, several series of undrained cyclic triaxial tests on

reconstituted and undisturbed pumice specimens were

performed as well as geotechnical investigations at sites of

pumiceous deposits. The major results are as follows:

(1) Although relative density has some noticeable effect on

the cyclic resistance of pumice, it was not as significant

when compared to that observed for hard-grained sands.

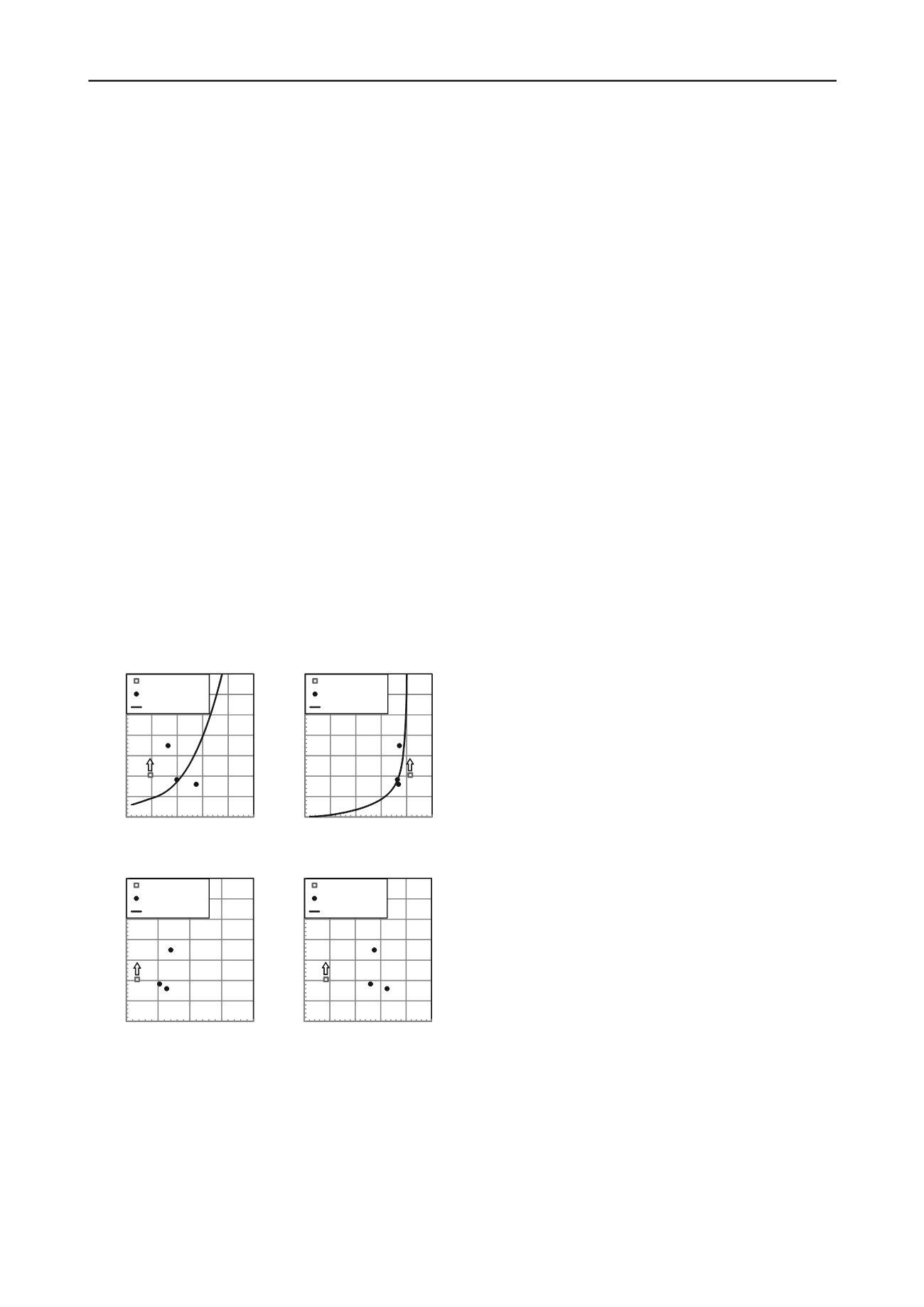

Figure 5 shows the plot of the (

CRR

)

triaxial

vs (

CRR

)

field

estimated from the following empirical formulas: (a) from

normalized CPT tip resistance,

Q

tn

,

cs

(Robertson and Wride,

1998); (b) normalized shear wave velocity

V

S

1

(Andrus and

Stokoe, 2000); (c) dilatometer modulus,

E

D

(Tsai et al. 2009);

and (d) horizontal stress index,

k

d

(Tsai et al. 2009). Note that

for Carr Rd specimen, only

DA

=2% was achieved in the tests

and therefore, (

CRR

)

triaxial

should be higher than the value

measured, as indicated by the arrow sign in the figure. It can be

seen that penetration-based methods (CPT and DMT) do not

correlate well with the laboratory-obtained cyclic resistance. It

is hypothesized that the shear stresses during penetration were

so severe that particle breakage formed new finer grained

materials, the mechanical properties of which were very

different from the original pumice sand. On the other hand,

empirical method based on shear wave velocity seemed to

produce good correlation with liquefaction resistance of

pumiceous soils. Although the

V

s

in this research was obtained

from SDMT where the penetrating rod may have induced

particle breakage in the adjacent zone, the shear waves travelled

through the intact grains and not on the crushed ones.

(2) As the confining pressure was increased, the liquefaction

resistance curve of reconstituted pumice specimens was

shifted downward and the resistance reduced, consistent

with the observations made on hard-grained sands.

(3) During the initial stage of shearing, the increase in surface

area (as a result of particle crushing ) was small; however,

as the liquefaction stage was reached, the surface area

increased remarkably because large strains occurred with

associated translation and rotation of particles causing the

higher degree of crushing.

(4) Among the in-situ methods tested, the empirical method

based on shear wave velocity seemed to produce good

correlation with liquefaction resistance of pumiceous soils.

ACKNOWLEDGEMENTS

The study presented in this paper was part of a research work

supported by the New Zealand Earthquake Commission (EQC)

under grant number 10/589. the authors would also like to

thank Dr Andy Tai and Mr. Yi Lu of the University of

Auckland for the assistance in performing the experimental

works presented herein and Mr Andy O’Sullivan of Hiway

Geotechnical Ltd and Mr. Graham Blakeley of Aecom for the

in-situ sampling and boring information at the Waikato sites.

It should be mentioned that only 4 tests were performed in

this study, and more tests are required to validate this

observation. Detailed studies on the percentage of pumice in the

soil specimens may also be warranted.

REFERENCES

Andrus, R.D. & Stokoe, K.H., II. 2000. Liquefaction resistance of soils

from shear-wave velocity.

J. Geotech. Geoenv. Engrg., ASCE

,

126(11), 1015-1025.

Boulanger, R.W & Idriss, I.M. 2004. State normalization of penetration

resistances and the effect of overburden stress on liquefaction

resistance.

Proc., 11th Int Conf on Soil Dynamics and Earthquake

Engineering and 3rd Int Conf on Earthquake Geotechnical

Engineering

, Vol. 2, 484-491.

Miura, N. & Yamanouchi, T. 1971. Drained shear characteristics of

Toyoura sand under high confining stress,

Proc. of Japanese

Society of Civil Engineers

, 260: 69-79 (in Japanese).

New Zealand Standard 1986.

NZS 4402 : 1986 - Methods of Testing

Soils for Civil Engineering Purposes

. Part 2 Soil classification tests.

2.7 Determination of the solid density of soil particles. Test 2.7.2

Method for medium and fine soils.

Orense, R.P., Kiyota, T., Yamada, S., Cubrinovski, M., Hosono, Y.,

Okamura, M. & Yasuda, S. 2011. Comparison of liquefaction

features observed during the 2010 and 2011 Canterbury

earthquakes.

Seismological Research Letters

, 82 (6), 905-918.

Orense, R.P., Pender, M.J. and Tai, A. 2012. Undrained cyclic shear

behaviour of pumice sand,

Proc., Australia-New Zealand

Conference on Geomechanics

, 6pp.

Robertson, P.K. & Wride, C.E. 1998. Evaluating cyclic liquefaction

potential using the cone penetration test.

Canadian Geotechnical

Journal

, 35(3), 442-459.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 50 100 150 200 250

C

yclic

R

esistace

R

atio,C

R

R

Q

tn,cs

Carrs Rd site

Mikkelsen Rd site

Empirical formula

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 50 100 150 200 250

C

yclic

R

esistace

R

atio,C

R

R

V

s1

Carrs Rd site

Mikkelsen Rd site

Empirical formula

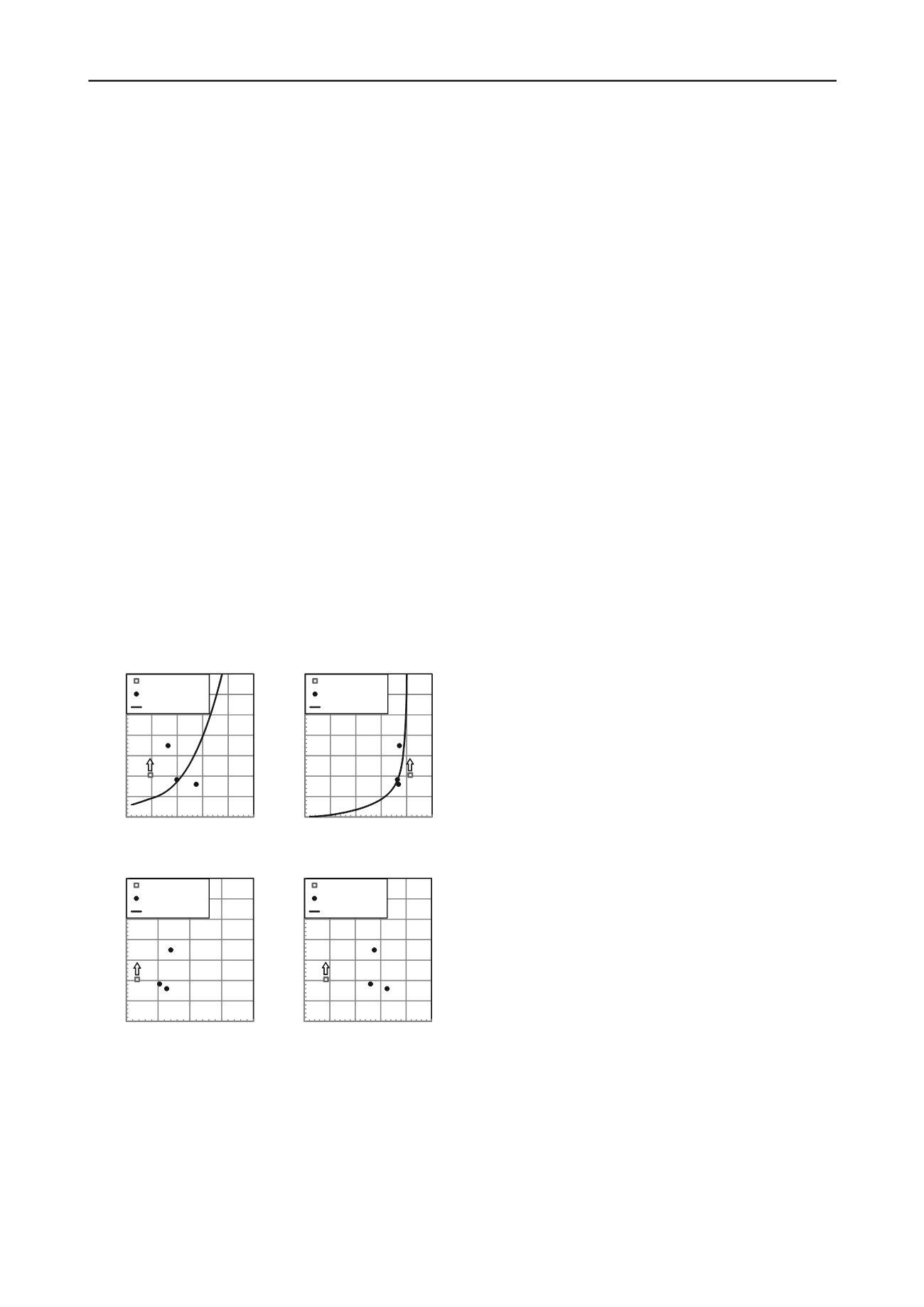

(a) CPT (b) V

s

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0

25

50

75 100

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 2 4 6 8 1

C

yclic

R

esistace

R

atio,C

R

R

k

D

Rollins, K.M. & Seed, H. B. 1988. Influence of buildings on potential

liquefaction damage.

Journal of Geotechnical Engineering, ASCE

,

116, GT2, 165-185.

Tsai, P.H., Lee, D.H., Kung, G.T.C. & Juang, C.H. 2009. Simplified

DMT-based methods for evaluating liquefaction resistance of soils.

Engineering Geology

, Vol. 103, No. 102, 13-22.

Yamamoto, Y., Hyodo, M. & Orense, R. 2009. Liquefaction resistance

of sandy soils under partially drained condition.

Journal of

Geotechnical and Geoenvironmental Engineering

, ASCE, Vol. 135,

No. 8, 1032-1043.

C

yclic

R

esistace

R

atio,C

R

R

E

D

Carrs Rd site

Mikkelsen Rd site

Empirical formula

0

Carrs Rd site

Mikkelsen Rd site

Empirical formula

(c) DMT dilatometer modulus (d) DMT horizontal stress index

Figure 5: Comparison between laboratory obtained CRR and those from

field-derived parameters.