1568

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

parameter.

L

N N

was termed cycle ratio. Booker et al. (1976)

proposed the following simplified alternative of the equation:

1/2

2

arcsin

u

L

N

r

N

(2)

Since the equations are identical in shape, both will be

termed Seed et al model in this paper. The Seed et al. model

requires definition of three parameters, which are

N

,

N

L

and

.

N

can be determined from the ground motion time history

calculated from a total stress site response analysis.

N

L

is most

often determined from simplified liquefaction approach.

Extensive tests have been performed to determine the bounds of

the pore pressure measurements expressed in terms of cycle

ratio and representative value of

. Lee and Albaisa (1974)

proposed upper and lower bounds, while Booker et al. (1976)

recommended

= 0.7 for clean sands. Polito et al. (2008), based

on 145 cyclic triaxial tests, proposed empirical equation for

.

While the shape of the Seed et al. model was shown to agree

well with the measured build-up of pore pressure, the model has

its limitations. The main drawback of the model is that since

N

and

N

L

have to be defined a priori, it cannot be used for a

coupled numerical analysis. Another limitation of the models is

that it cannot be used for non-liquefiable soils for which

N

L

cannot be defined.

This study proposes the following modified equation, which

is based on the model of Seed et al.:

1/2

1.0

2

arcsin

u

u

r

dD

dr

D

)

(3)

where,

= incremental residual pore pressure ratio,

D

=

damage parameter,

D

ru

=1.0

is the value of damage parameter

D

at

initiation of liquefaction and

is an empirical constant. It

should be noted that

N

and

N

L

of Eq. (2) are replaced by the

damage parameters

D

and

D

ru

=1.0

, respectively. The damage

parameter, which is essentially a variable which contains

parameters that define the strain / stress history and can

uniquely relate to build-up of pore pressure for a given soil, is

defined as follows:

u

dr

(

t

D SR CSR

(4)

where, where

SR

= shear stress ratio (shear stress normalized to

initial effective vertical stress),

CSR

t

= threshold shear stress

ratio below which residual pore pressure is not generated,

=

length of shear stress path,

= calibration parameter. The

equation for the damage parameter is very similar to the

function proposed by Ivsic (2006). Two parameters for

D

,

which are

CSR

t

and

, should be selected from trial and error.

CSR

t

can be selected from visual inspection of the

CSR

– N

curve. The second parameter,

, is calculated by averaging. The

concept of the damage parameter implies that

D

at liquefaction

for a given soil, which will be termed

D

ru

=1.0

in this paper,

should be a constant independent of

SR

. Therefore,

D

ru

=1.0

of the

CSR – N

curve should be all identical. In reality, although the

values of

D

ru

=1.0

for different

CSR

s may be similar, but they will

not be identical. In other words, it might not be possible to

uniquely relate to the pore pressure using a single value of

for

all

SR

s. Through several trials, it was shown that the optimum

value of

can be calculated by averaging using the following

equation, which is derived from Eq.(4):

1

1

log

1

log

log

1

M

Avg

i

N i

N i

CSR CSR CSR CSR

t

i

t

i

M

(5)

where

M

= number of data points of

CSR

–

N

curve,

i

and

i

+1

denote two adjacent data points of the curve.

After the selection of the parameters, it is recommended that

the corresponding

CSR

–

N

curve be back-calculated and

compared to the target curve to confirm that the appropriateness

of the parameters. In back-calculation, one of the measured data

points is selected as the reference data point. The rest of the data

points for the back-calculated

CSR

–

N

curve are calculated

relative to the reference data point. The following equation can

be used to calculate

CSR

i

for a given

N

i

log

log

10

ref

i

ref

t

Avg

N

N

CSR CSR

i

t

CSR

CSR

(6)

where,

CSR

ref

= CSR

of the reference data,

N

ref

= number of

cycles of reference data. The full back-calculated

CSR

–

N

curve can be constructed by using Eq(4). for a range of

N

i

. This

CSR

t

and

selection process should be repeated until a best fit

CSR

–

N

curve is obtained.

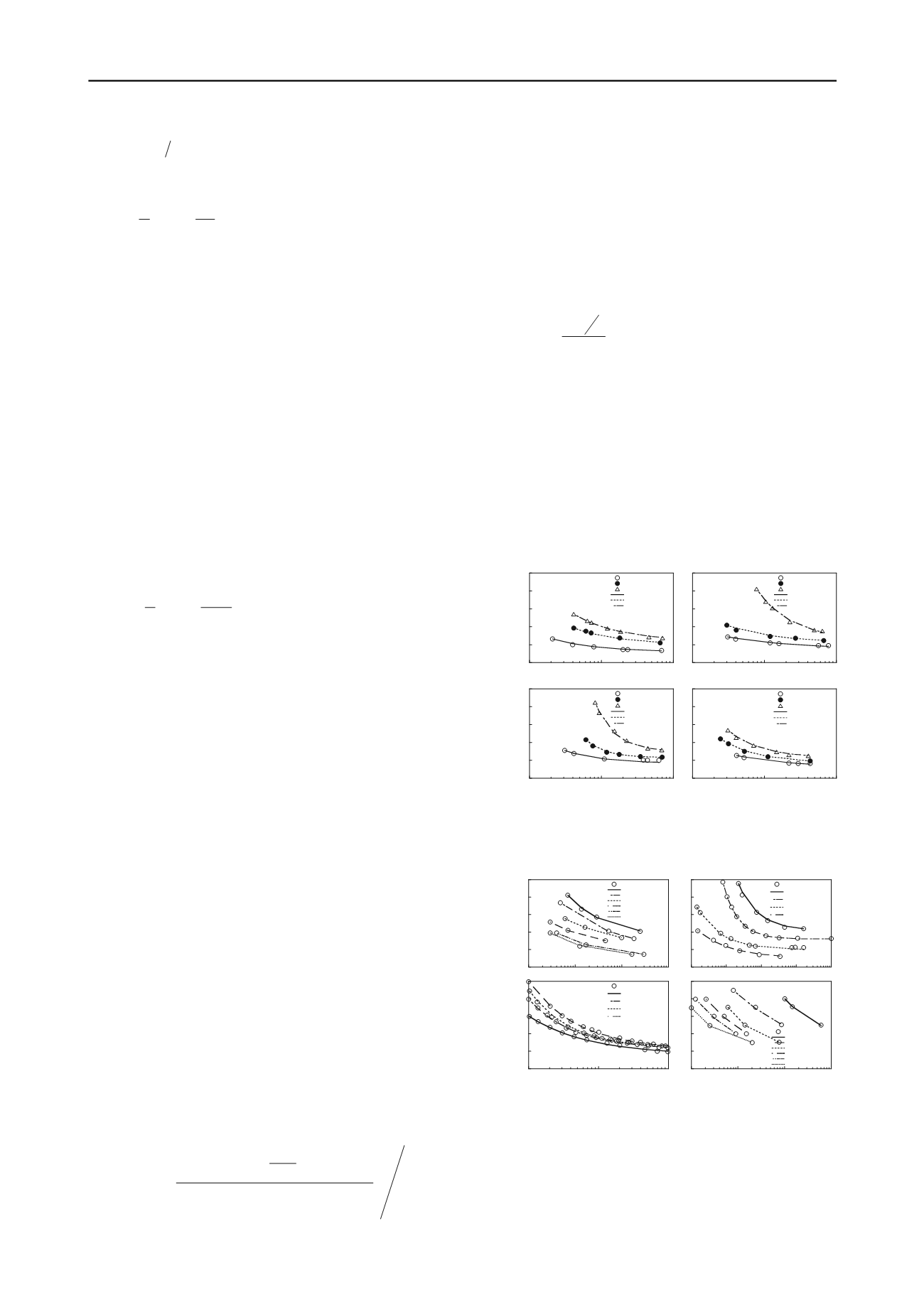

The applicability of the recommended procedure for

selecting

CSR

t

and

is evaluated through comparison with

extensive sets of data. Figure 1 -

Figure 3

compare the predicted

CSR

–

N

curves with the published data. It is shown that the

recommended process provides good estimates of the

measurements for all cases, which encompass a wide range of

soils and densities.

0

0.2

0.4

0.6

0.8

1

1

10

100

Dr=40%

Dr=67%

Dr=77%

Calculated (Dr=40%)

Calculated (Dr=67%)

Calculated (Dr=77%)

Cyclic stress ratio, CSR

(a)

0

0.2

0.4

0.6

0.8

1

1

10

100

Dr=31%

Dr=53%

Dr=80%

Calculated (Dr=31%)

Calculated (Dr=53%)

Calculated (Dr=80%)

(b)

0

0.2

0.4

0.6

0.8

1

1

10

100

Dr=41%

Dr=58%

Dr=78%

Calculated (Dr=41%)

Calculated (Dr=58%)

Calculated (Dr=78%)

Cyclic stress ratio, CSR

Number of cycles, N

(c)

0

0.2

0.4

0.6

0.8

1

1

10

100

Dr=45%

Dr=65%

Dr=80%

Calculated (Dr=45%)

Calculated (Dr=65%)

Calculated (Dr=80%)

Number of cycles, N

(d)

Figure 1. Comparison of measured (Carraro et al. 2003) and predicted

CSR – N

curves: (a) Clean Ottawa sand, (b) Ottawa sand with 5% non-

plastic silt, (c) Ottawa sand with 10% non-plastic silt, (d) Ottawa sand

with 15% non-plastic silt.

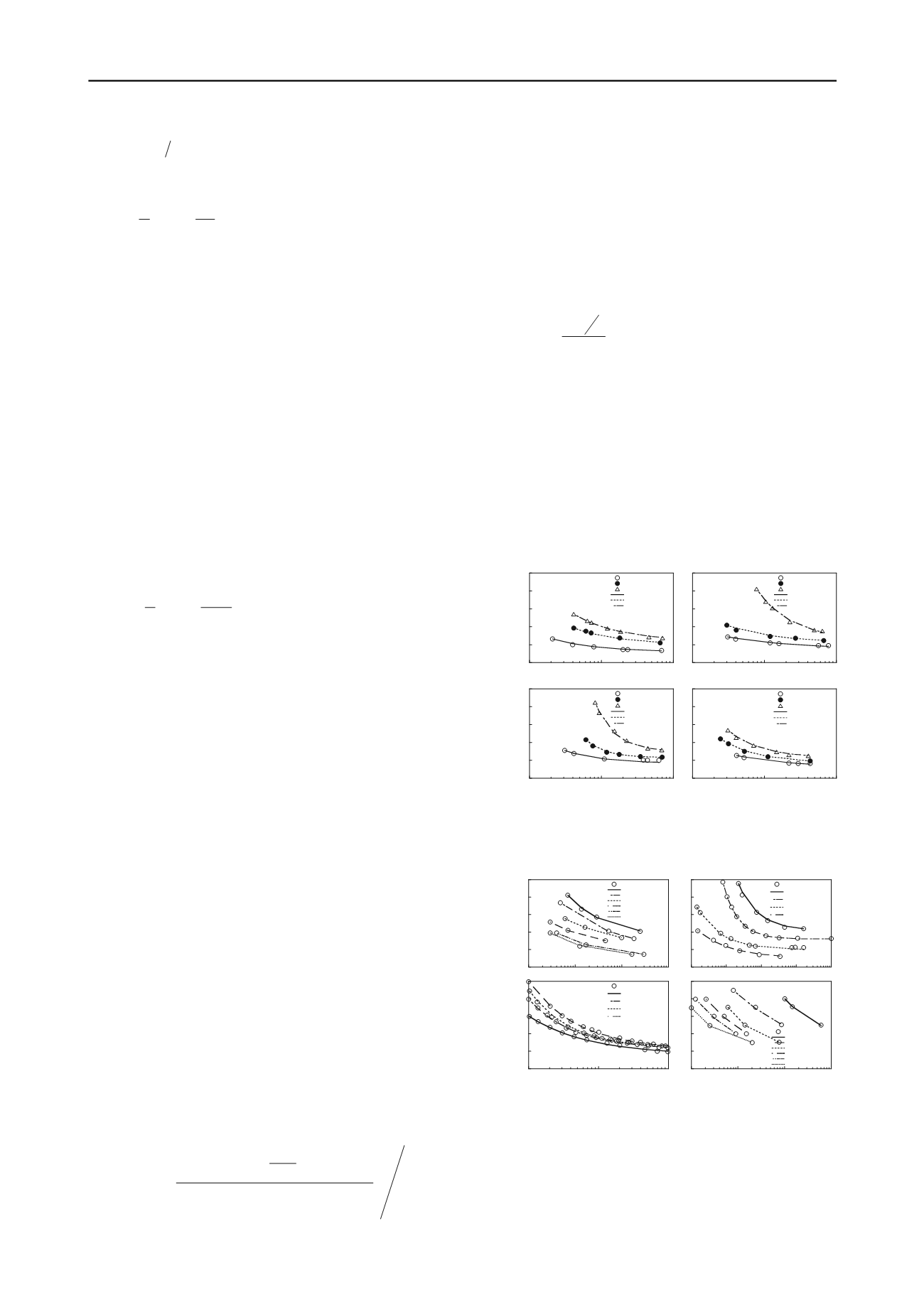

0

0.1

0.2

0.3

0.4

0.5

1

10

100

1000

Measured

Calculated (FC=0%)

Calculated (FC=5%)

Calculated (FC=10%)

Calculated (FC=15%)

Calculated (FC=22%)

Calculated (FC=30%)

Cyclic stress ratio, CSR

(a)

0

0.1

0.2

0.3

0.4

0.5

1

10

100

1000

Measured

Calculated (FC=0%)

Calculated (FC=10%)

Calculated (FC=30%)

Calculated (FC=42%)

(b)

0

0.1

0.2

0.3

0.4

0.5

1

10

100

Measured

Calculated (Dr=50%)

Calculated (Dr=60%)

Calculated (Dr=68%)

Calculated (Dr=70%)

Cyclic stress ratio, CSR

Number of cycles, N

(c)

0

0.1

0.2

0.3

0.4

0.5

1

10

100

1000

Measured

Calculated (FC=0%)

Calculated (FC=5%)

Calculated (FC=13%)

Calculated (FC=20%)

Calculated (FC=45%)

Calculated (FC=60%)

Number of cycles, N

(d)

Figure 2. Comparison of measured and predicted

CSR – N

curves: (a)

Troncoso and Verdugo (1985), (b) Xenaki and Athanasopoulos (2003),

(c) (Park et al. 1999) , (d) Koester (1994).