1577

Technical Committee 203 /

Comité technique 203

were performed under regulated vacuum confinment of about

95 kPa. A typical testing sequence was as follows:

1. Prepare sample by pluviating through tube into split

mold and membranes. Assemble remaining parts of device

while under vacuum, then remove inner and outer split

molds.

2. Perform low-amplitude RC (γ≈10

-4

%) versus time

(1,2,5,10,20 min...) to asses duration-of-confinement effects,

if any.

3. Perform TOSS uniform cyclic test at low amplitude

(τ=10 kPa) for 200 cycles of loading. Record and inspect

hysteresis loops.

4. Perform low amplitude RC to asses any changes to

G

max

due to TOSS loading.

5. Repeat (3),(4) by increasing TOSS stress level until

specimen fails or device reaches maximum displacement.

Usually steps of Δτ=10kPa were chosen.

For an irregular loading history, the same sequence was

followed where the absolute value of peak stress was gradually

increased for each stage.

3.2

Test Results

Preliminary tests have examined several behavior phenomena

discussed in the literature. Among the aims of these tests were

to shed light on several questions.

1. Can very different sorts of tests yield similar fundamental

properties, namely shear wave velocity? Results from many

tests have shown that the low amplitude shear wave velocity

measured from RC tests and bender element tests in a triaxial

cell are identical (Anka 2012).

2. How do TOSS and RC results compare vs. strain level?

The testing so far has shown that, in the strain range where both

are effective and accurate, they produce the same results. RC

tests can measure modulus as much lower strain levels than

TOSS. At very high strains, TOSS measurements of damping

are much easier to obtain, as resonance is difficult to maintain at

strains near failure. Since the TOSS device can be strain-

controlled, the operator may closely monitor behavior near

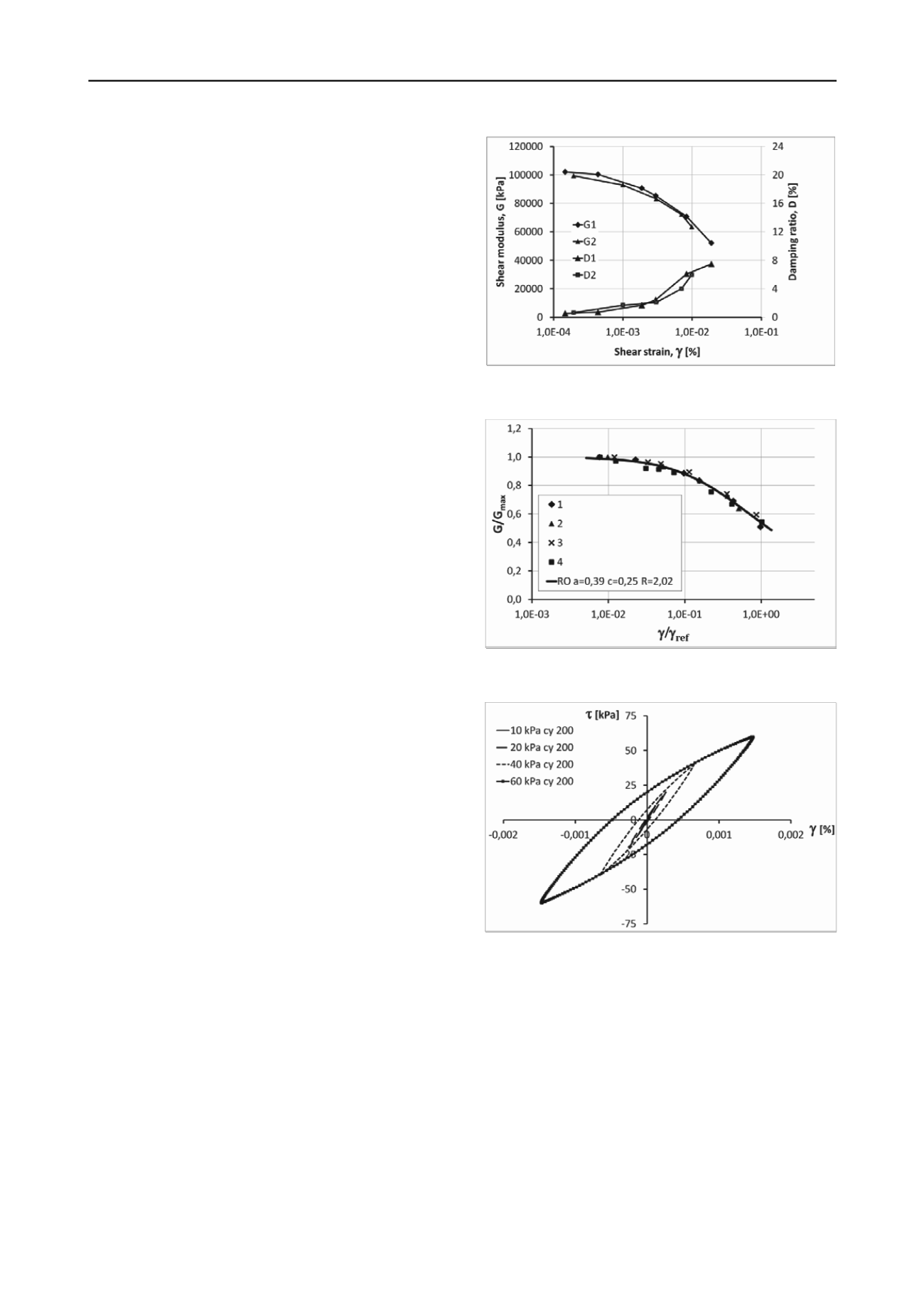

failure and avert collapse. Examples or RC test results are

shown in Figure 3 where two sets of modulus reduction and

damping sequences are shown. Data can be further processed to

include reference strain. The advantage of using a

dimensionless strain is that confinement effects are eliminated.

Shown in Figure 4 are four such tests where confining stresses

ranged from 50 to 200 kPa.

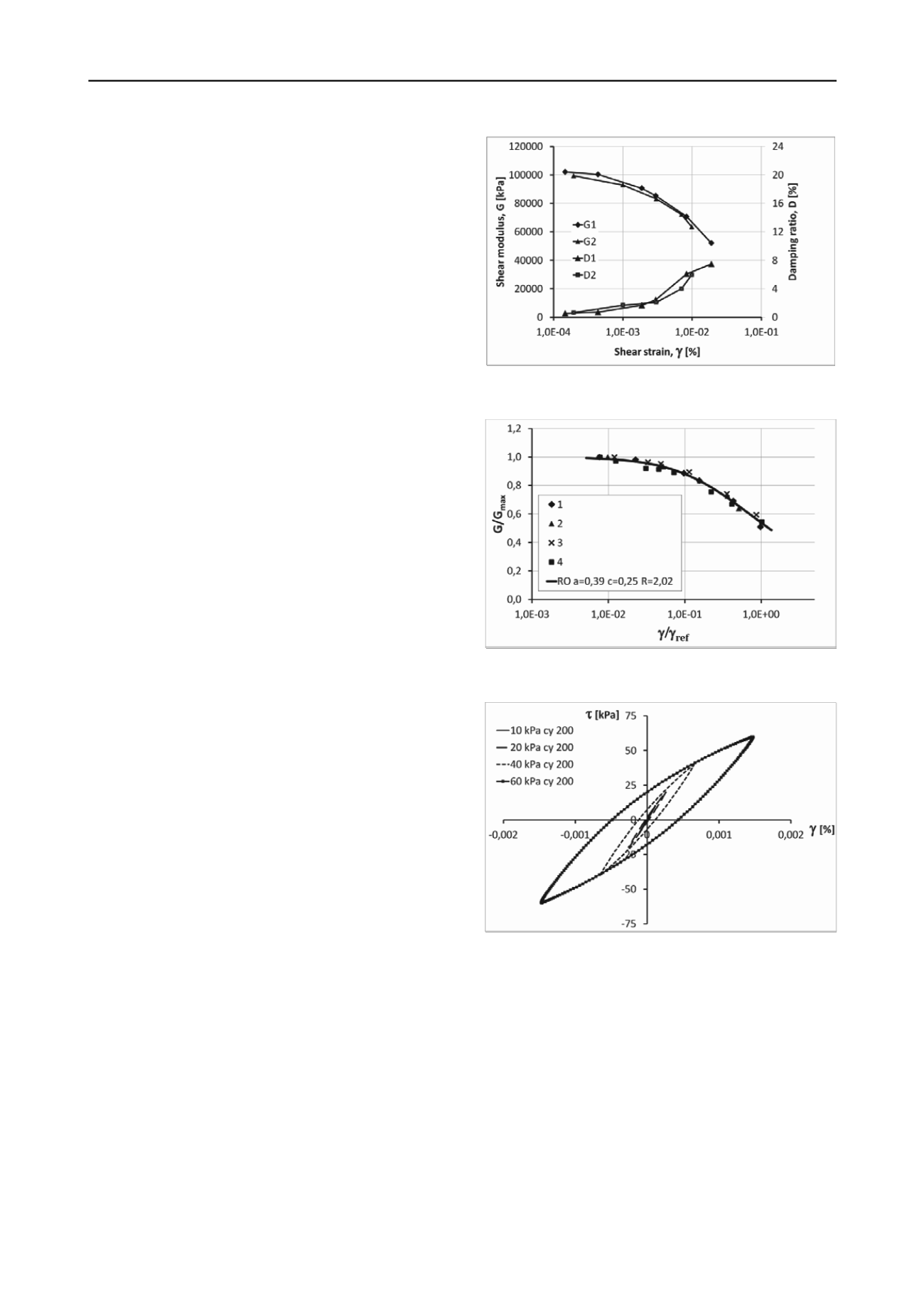

Results of a TOSS cyclic test are shown in Figure 5. Each

loop corresponds to a different peak shear stress level. Note the

changes in secant modulus as the strain levels increase.

Additionally hysteretic damping also increases with increasing

strain, indicated by the larger areas of the stress-strain loops.

3. Do number of loading cycles have an impact on stress-

strain behavior? For most of the testing performed so far, there

is a definite effect. However, the cyclic behavior tends to

stabilize after 100-200 cycles. Since these tests have been

performed on dry soil, no pore pressure behavior has been

examined yet. Figure 6 shows selected hysteresis loops of a

TOSS test performed for 200 load cycles. The soil is stiffening

with each cycle as shown by the more vertically inclined loops.

Damping is decreasing, evidenced by the narrowing of the loop

area.

Figure 3. Modulus reduction and damping for two RC tests on Danube

Sand.

Figure 4. Modulus reduction vs. dimensionless strain, Ramberg-Osgood

curve fitted to the test data.

Figure 5. TOSS results for four different stress levels. This is cycle no.

200 for each stage of the test.

4. Do irregular load histories behave as predicted by soil

models? This is a question that cannot be fully answered here

since discussion of soil models and cylic loading criteria is

rather complex. However, based on preliminary data, one can

predict behavior under arbitrary loading histories if the G/G

max

vs. γ curve is defined by RC or TOSS (or more typically, both)

test data. One irregular load history was used to “track” the

progress of the stress-strain curve across the initial backbone

curve of the test. Contrary to the theory according to Pyke

(1979) the stress strain curve does not follow the backbone

curve at the time of crossing. Several tests have been performed

and this particluar effect is yet to be seen.