1576

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

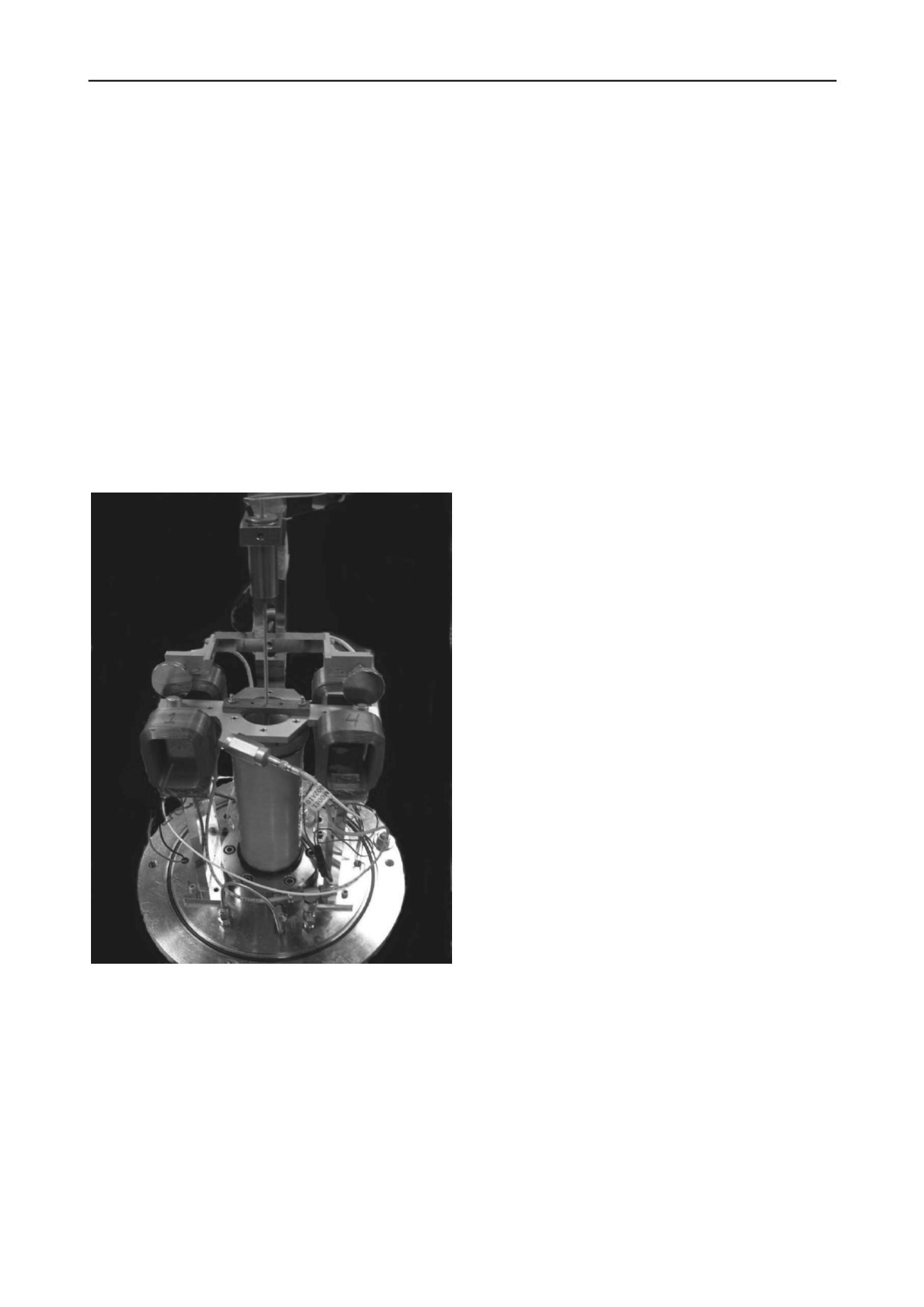

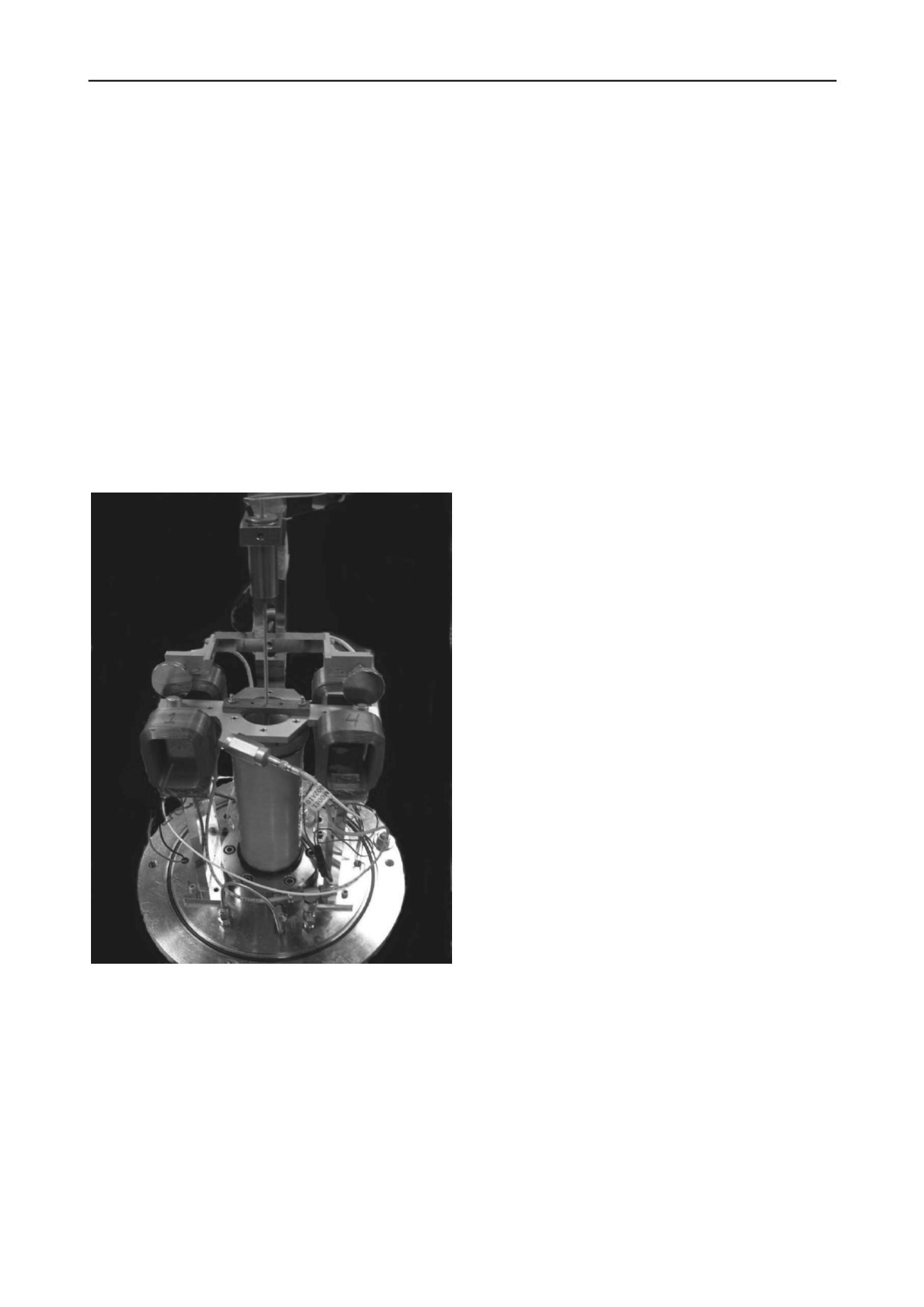

capable of loading and measuring at higher torques and wider

strain ranges. It is a combined resonant column (RC) and

torsional simple shear (TOSS) device. The device can drive a

cylindrical specimen (ID=4.0 cm, OD=6.0cm, L=14cm) in

torsion with the use of permanent magnets and electric coils.

The specimens are covered by latex memebranes inside and out

and are fixed at the base and free to rotate at the top, where the

drive head is attached. The drive head consists of a coil and

magnet system where there is open space between the magnet

and coils. An accelerometer is used for measuring displacement

during RC testing; the nature of acceleration measurement

allows for very high accuracy at low amplitudes (γ=10

-4

%).

Proximitors measure the gap distance between their targets and

are used for measuring rotation (strain) during TOSS tests.

Since they are DC output devices, there is no low-frequency

roll-off as in accelerometer measurements. An LVDT measures

vertical displacement of the drive head. Its inner core is

connected by a rigid threaded rod to the drive head. The other

end of the rod is suspended on a spring, providing a counter-

force to the drive head’s weight without impeding the RC

measurements (Figure 2).

Figure 2. RC-TOSS device with hollow-cylinder specimen, coils,

magnets, accelerometer, proximitor targets and LVDT.

The upper and lower specimen ring have a porous interface

and can provide saturation to the specimen. Pore pressures are

measured at the confining cell’s outer port. Due to the extensive

electronics, the confining medium is air.

The driving system allows for individual control of the

applied shear stresses as well as the cell pressure (with use of a

pressure chamber) and the hollow cylindrical specimens have

the great advantage of having nearly-uniform shear stress

distribution throughout its cross-section.

For the RC tests, the specimen is driven in a harmonic

manner back and forth in torsion at very low strain amplitudes

with varying frequencies in order to find resonance. From the

obtained resonance frequency, the shear wave velocity and the

shear modulus can be obtained.

The RC test is capable of measuring the damping ratio as a

function of strain amplitude by either the logarithmic decrement

or half-bandwidth method. For low strain amplitudes, the half-

bandwidth method works well. At higher amplitudes, it is often

difficult to get stable readings and the log-decrement method

generally works better. By using a cutoff switch that turns the

coils into open circuits there is very little coil-generated

damping during log decrement measurements. Additionally, the

drive system can be given an offset DC voltage to apply static

stress/strain then resonated with a low-amplitude signal to

examine effects of different stress ratios (σ

1

/σ

3

) and static shear

stress/strain (τ

static

,γ

static

) on shear modulus.

With use of the data acquisition system and computer,

various cyclic and arbitrary load histories can be applied.

Hysteresis and secant/tangent moduli can then be computed

from the aquired data. The unique design of the testing device

allows for both RC and TOSS tests to be run on the same

specimen any number of times and in any sequence. A

particularly useful sequence is to perform low-amplitude RC

between different stages of TOSS testing to evaluate the effects

of each TOSS stage on the “fundamental” property G

max

. The

baseline value of G

max

allows data to be normalized by

reference strain (γ

ref

) or other quantities. The same values for

G

max

have been produced in bender element tests on triaxial

specimens of the same soil.

The drive system uses a 500-watt DC power amplifier that

can be current-controlled. Under current (rather than voltage)

control, the device can consistently deliver the same stress level

during a test, even if the coils heat up. Using neodymium

magnets, the device can generate shearing stresses greater than τ

= 200 kPa. Driving a specimen at resonance would increase the

available force by a factor of 2-3x.

2.2

RC-TOSS Software

The device is controlled via Visual Basic for applications

(VBA) within Excel. Resonant column testing is normally

performed manually by seeking resonance with a frequency

oscillator, oscilloscope, and precision digital multi-meter.

However, the computer can perform frequency sweeps and

measure accelerometer RMS output and period to capture

resonance as well. More importantly, the TOSS testing can be

performed as stress- or strain-controlled using a variety of

waveforms. Most commonly, triangle wave loading is used for

uniform cyclic loading or cyclic loading with static offset. Data

acquisition of 200 different cycles, 200 data points per cycle are

routine. The number of data points and recorded cycles is

limited only by software memory. Arbitrary loading hisories

can be used as well, most often to study effects of past load

history and verify Masing criteria. Data is reduced and plotted

through VBA and Excel Macros. Further data analysis can be

performed later within Excel.

3 TESTING DANUBE SANDS

Candidates for initial testing were sands of various gradations

found along the main channel and floodplain of the Danube

River. These sands are of particular interest and importance due

to building development along the Danube throughout Hungary,

the widely varying in-situ conditions of the sands, and the

potential for drastic strength reductions and liquefaction during

seismic events.

3.1

Testing Sequence

Initial testing performed on the sands was as much to verify

device performance as it was to establish dynamic properties. In

order to verify proper operation of the equipment, most tests