1536

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

were carried out at loading frequency in the range from about

0.01 Hz to 0.2 Hz.

Menq (2003) used both an RCTS device and an MMD

(Multi-Mode Resonant) device to investigate the dynamic

properties of gravelly soils. The RCTS device is capable of

performing on the same soil specimen both the torsional

resonant column (RC) test at high loading frequency (i.e., the

resonant frequency) and in the nonlinear range and the cyclic

torsional shear (TS) test at much lower frequencies, simply by

changing the amplitude and frequency of the current in the drive

coils and the motion monitoring devices used to record the

specimen response (Isenhower 1979; Ni 1987; Hwang 1997).

Because the same specimen can be subjected to both the RC and

TS tests, it eliminates the variability due to testing different

specimens or testing the same specimen subjected to a different

stress history (Darendeli 2001). The test specimen for RC or TS

testing typically has a diameter in range from 36 to 76 mm and

a height from 72 to 152 mm (Menq and Stokoe 2003). To

accommodate gravelly specimens with relatively large particle

sizes, the MMD was developed and is capable of testing

specimen with 152 mm in diameter and 600 mm in height in

different measurement modes, including the torsional resonance

mode similar to resonant column tests.

Based on the test results, Menq (2003) used the modified

hyperbolic model suggested by Darendeli (2001) to model for

shear modulus reduction of gravelly soils:

]) / ( 1[1

/

max

a

r

GG

(1)

5.0

5.0

0

6.0

) /

(

12.0

u

C

a

u

r

p

C

(2)

) /

log(

1.0 86.0

0

a

p

a

(3)

where the reference strain

r

(%) is

at G/G

max

= 0.5,

a

is the

curvature coefficient,

C

u

is the uniformity coefficient,

0

’

is the

effective isotropic confining pressure, and

p

a

is the atmospheric

pressure (1 atm).

3 MECHANICAL PROPERTIES OF TESTED GRAVEL

Two types of gravel were tested for potential use as engineered

fill in this study. They are aggreagates derived from processing

crushed stone mined from a rock quarry, consisting of angular

and hard particles, with one of them being poorly graded and

designated as PA and the other being relatively well graded and

designated as WA. Three batches of the WA material (WA-1,

WA-2, and WA-3) and one batch of the PA material (PA-1)

were taken for testing.

Modified Proctor tests in accordance with ASTM D1557

were performed on the WA material (WA-1 and WA-3) after

removing/scalping particles greater than 19 mm in diameter.

The modified Proctor test is not applicable to the PA material

according to ASTM 1157. To be consistent with the modified

Proctor test, all the other laboratory tests were also performed

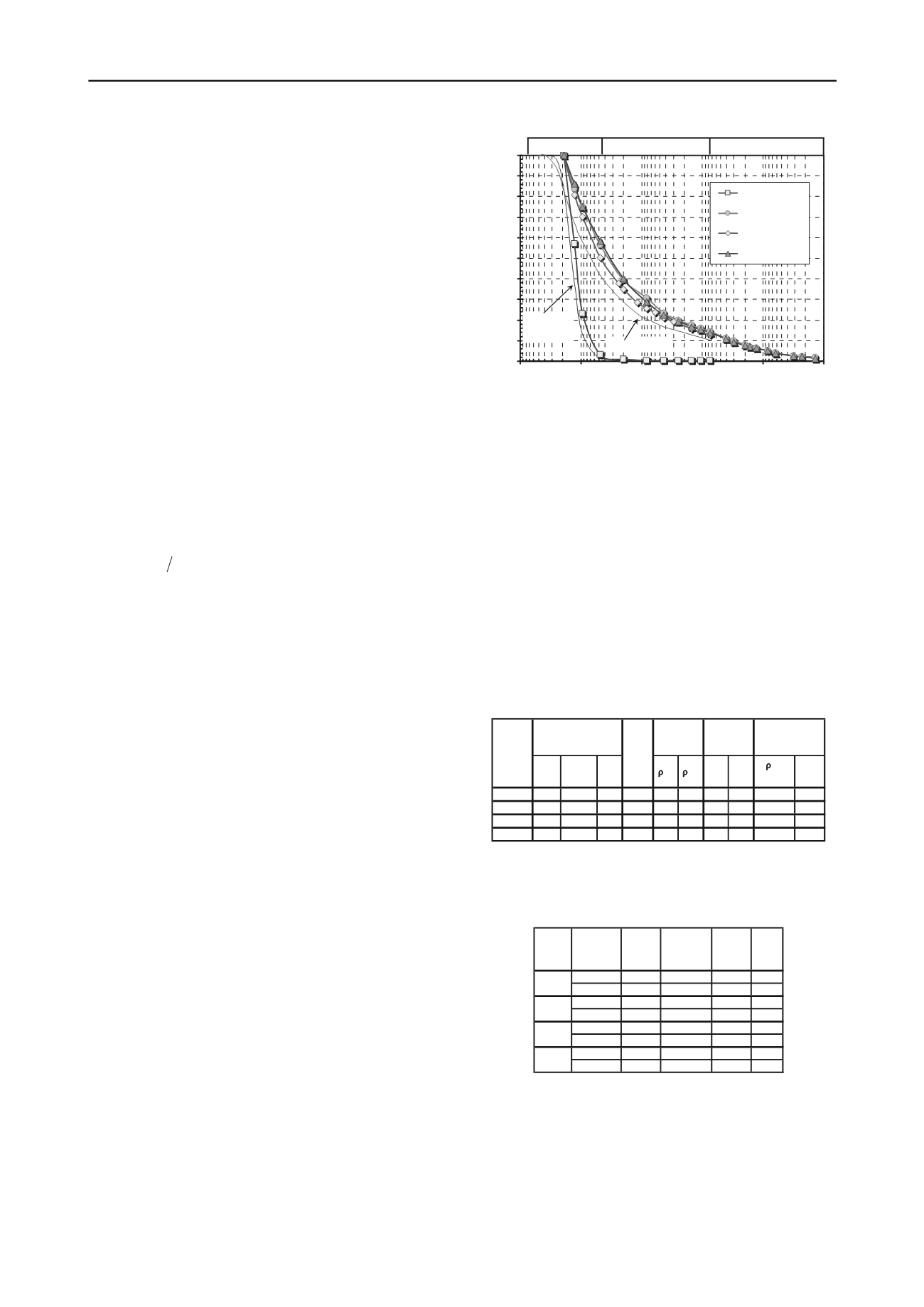

on the scalped material. Figure 2 shows the typical grain size

distribution curves for the tested materials (i.e., PA and WA), as

well as the grain size distribution curves of each batch of the

material after scalping particles greater than 19 mm in diameter

(i.e., PA-1, WA-1, WA-2, and WA-3).

In addition, maximum and minimum index densities were

obtained based on ASTM 4254 and ASTM 4253 for both the

PA material (PA-1) and the WA material (WA-1 and WA-3).

As seen in Table 1, the maximum index density of the WA

material determined using a vibratory table is very close to the

maximum density obtained by impact compaction in which the

moisture-density relationship is defined. But comparison shows

that the maximum index density of the WA material is

significantly (about 40%) higher than that of the PA material,

which is understandable as the voids between the larger

0

10

20

30

40

50

60

70

80

90

100

0.001

0.01

0.1

1

10

100

Grain Size (mm)

Percent Finer by Weight (%)

PA-1 (Scapled)

WA-1 (Scapled)

WA-2 (Scapled)

WA-3 (Scapled)

Typical

PA

Typical WA

Gravel

Sand

Fines

Figure 2. Grain size distribution curves of the unscalped and scalped

(tested) gravel specimens.

particles of the WA material are filled with smaller particles.

From each batch of the material, a pair of specimens

designated as A and B were created for the RCTS tests. The pair

of specimens from each batch of the WA material were

separately remolded at the optimum moisture content to

approximately 95% and 100% of the maximum dry density

determined in the modified Proctor test. And the pair of

specimens of the PA material were remolded to relative

densities of about 80% and 100% at a moisture content of about

1%. All specimens were compacted to the target densities using

a hammer drill fitted with a specifically designed circular steel

face of 146 mm in diameter.

After the RCTS tests were completed, more index tests such

as the water content and dry density were performed on each

specimen, and the results are summarized in Table 2, including

the derived degrees of saturation and void ratio.

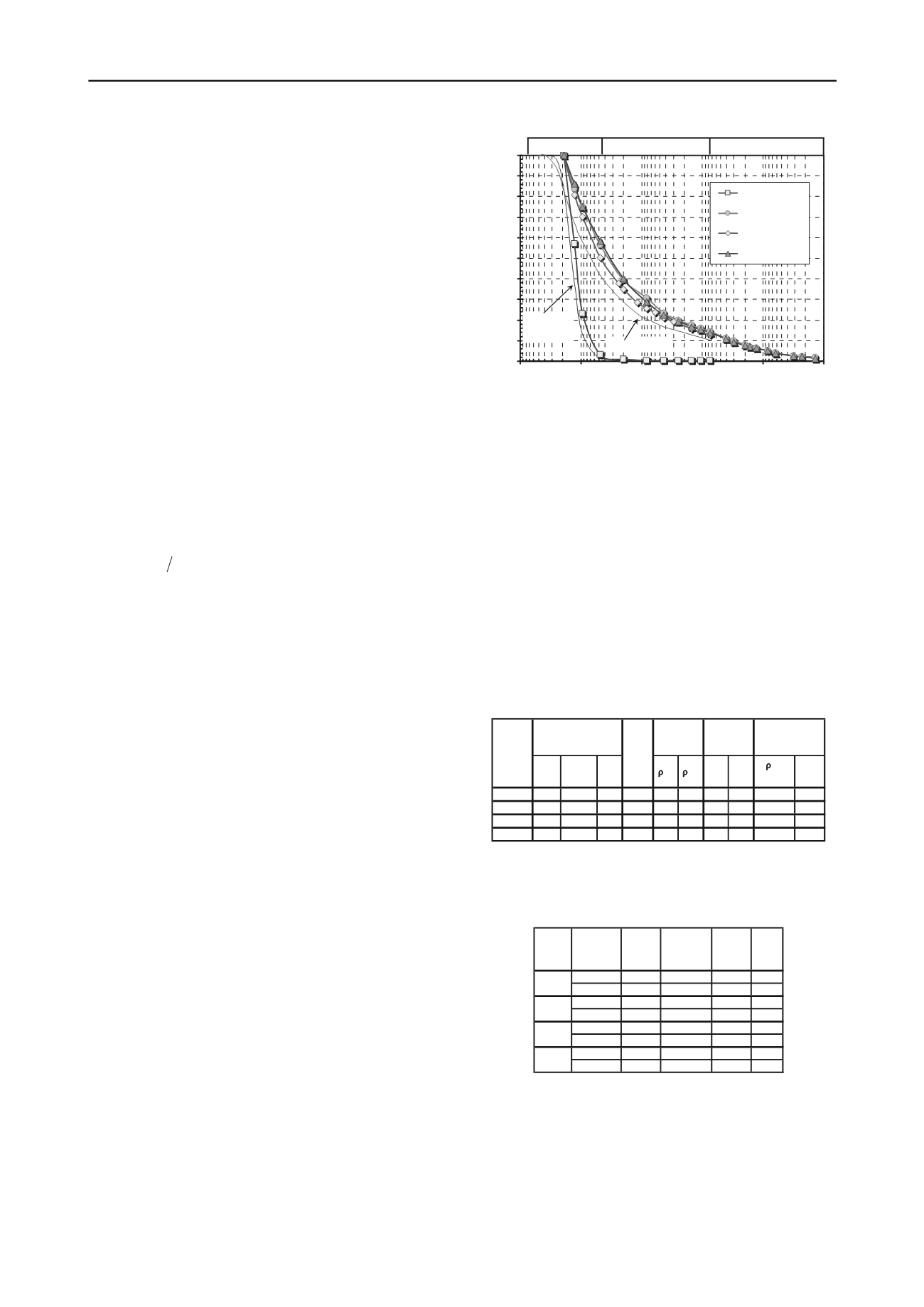

Table 1. Mechanical properties of scalped gravel samples.

D

50

(mm)

C

u

C

c

min

max

e

min

e

max

max

(Mg/m

3

)

w

opt

(%)

PA-1 11.8 2.1 1.3 2.83 1.39 1.64 0.73 1.04 -

-

WA-1 3.4 174.5 3.81 2.72 1.67 2.30 0.18 0.62 2.31 0.653

WA-2 -

-

-

2.72 -

-

-

-

2.30 0.469

WA-3 3.2 150.6 4.87 2.82 1.67 2.27 0.24 0.69 2.34 0.653

Index Void

Ratio

Moisture-

Density

Relationship

Sample

Name

Grain Size

Distribution

G

s

Index

Density

(Mg/m

3

)

Note: D

50

is the particle diameter corresponding to 50% passing; C

c

is

the coefficient of curvature, G

s

is the specific gravity, and w

opt

is the

optimum moisture content.

Table 2. Mechanical properties of gravel specimens tested in the RCTS

device.

Sample

Name Specimen

Water

Content

(%)

Saturation

(%)

Dry

Density

(Mg/m

3

)

Void

Ratio

A

1

3.5

1.57 0.81

B

0.8

3.2

1.66 0.70

A

6.4

72.1

2.19 0.24

B

6.1

85.5

2.27 0.19

A

5.5

59.8

2.17 0.25

B

4.4

65.3

2.30 0.18

A

5.8

61.5

2.23 0.27

B

6.2

87.2

2.35 0.20

PA-1

WA-1

WA-2

WA-3

4 RCTS TESTS ON COMPACTED GRAVEL

During RCTS testing, the specimen is sealed in a membrane,

and the pore pressure in the specimen is vented to atmosphere

pressure. From the results of cyclic triaxial tests on Toyoura

sand, Kokusho (1980) indicated that the drained tests and the

undrained tests give almost identical strain-dependent variation

of the modulus within the strain level from 10

-4

% to 0.5%.

Since the gravel specimens have larger permeability due to the