1412

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Sampling of clay was performed at one

to three different

sampling levels at each test site. In all, twenty-two different

types of clay were investigated in the study. The different soils

are listed together with their base characteristics in Table 1.

2.2

Investigation methods

The investigations required large uniform samples with

preserved properties also in the “elastic” small strain region.

The size of the samples should allow taking out a fairly large

number of “identical” test specimens.

Sampling of the clay was performed with a new sampler

constructed at SGI in 2009 with the aim of obtaining large high

quality samples in all types of mainly soft to medium strength

fine-grained soil (Larsson et al. 2012). The sampling tube is

about 1 m long with an inner diameter of 200 mm. The samples

are cut into six parts, before being sealed and carefully

transported to the laboratory. In the laboratory, test specimens

of a diameter of 50 mm were trimmed from the part samples.

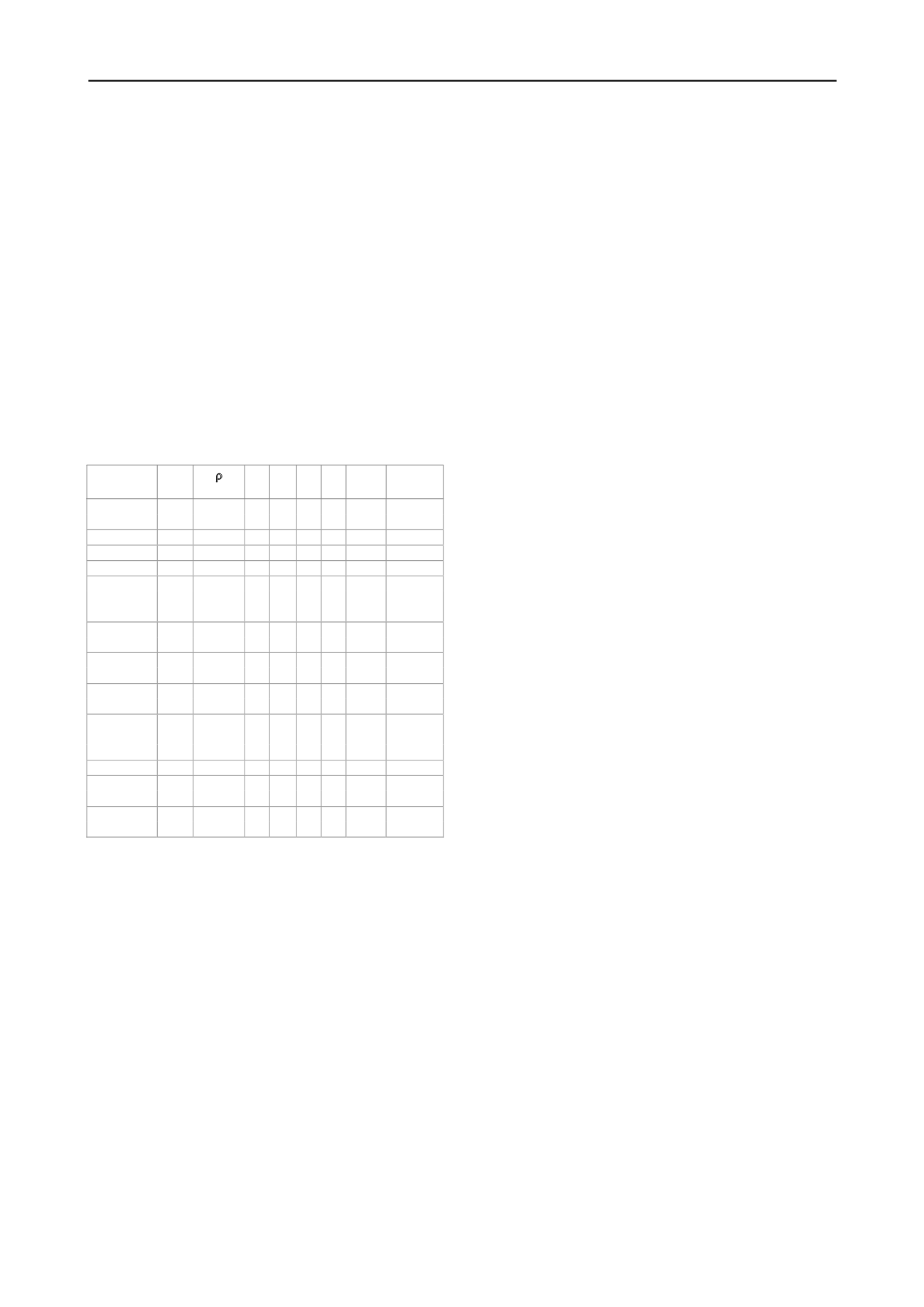

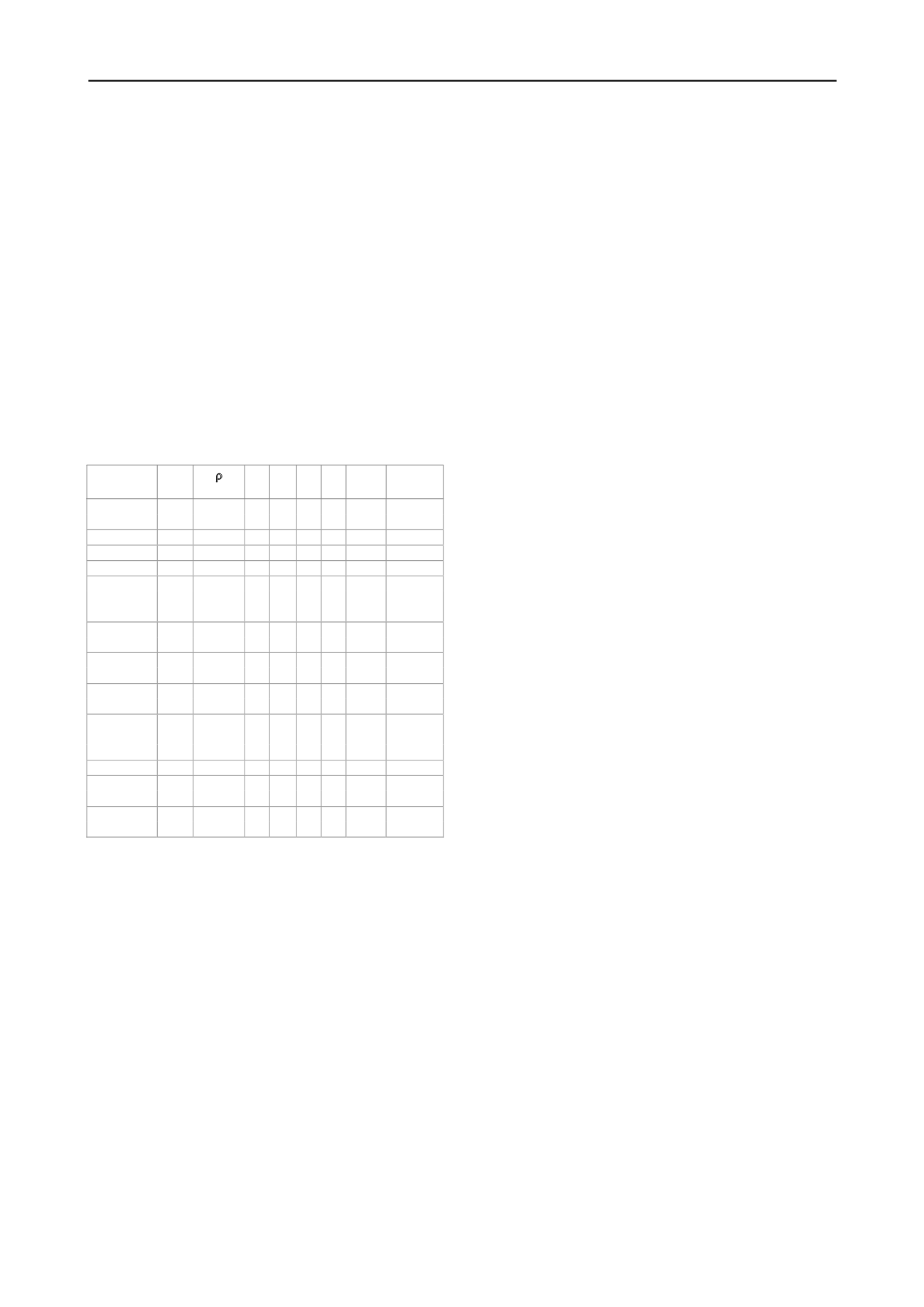

Table 1. Properties of the clays used in the investigations.

Test site

Depth

(m)

(Mg/m

3

)

w

P

(%)

w

L

1)

(%)

w

N

(%)

S

t

c

u-rem

1)

(kPa)

Org. cont.

(%)

Mellösa

5 1.45

35 94 101 10 1.02

3.4

8.5

1.54

25 87 86 10 1.58

1.3

Strängnäs

6 1.55

22 55 71 49 0.20

0.8

Norrköping

5 1.54

24 73 82 19 0.81

0.8

Linköping

5

1.6

24 71 73 16 1.25

1.0

Gläborg

4.5

1.58

25 50 79 185 0.08

1.3

6

1.6

25 46 75 180 0.10

1.0

10 1.69

23 42 62 190 0.11

0.8

Munkedal

5 1.83

21 39 42 28 0.86

1.8

10 1.69

25 45 61 253 0.12

1.0

Fultaga

6.5

1.63

28 64 81 94 0.21

1.1

10 1.66

24 53 63 95 0.37

0.9

Onsjö

3.6

1.68

22 56 59 25 0.96

0.6

7 1.59

27 57 71 219 0.14

0.8

Torpa

3.5

1.60

27 58 70 41 0.50

1.2

5.5

1.54

27 71 79 42 0.48

1.0

8 1.57

29 76 79 26 0.93

1.0

Fråstad

6.5

1.60

28 65 71 49 0.47

1.2

Äsperöd

2.7

1.69

24 54 54 15 1.60

1.9

7 1.59

26 57 74 100 0.27

1.6

Kattleberg

4.5

1.46

26 69 108 151 0.08

0.8

8 1.59

25 55 81 224 0.07

1.3

1)

Determined by the fall cone method

Control of the homogeneity showed no significant

differences across the diameter or along the length of the

samples. Evaluation of the specimen quality (or disturbance) in

accordance with the method proposed by Lunne et al. (1997),

where the change in void ratio,

e

, during reconsolidation to in-

situ stresses in the triaxial cell or in the oedometer is compared

to the initial void ratio,

e

0

, showed that the specimens generally

met the criteria of “very good to excellent quality”. For each test

site and sampling level, comparative CRS-oedometer tests and

static active triaxial tests were performed on samples taken with

the Swedish standard piston sampler (St II) for control and

comparison of the sample quality. For most part also the latter

samples met the criteria of very good to excellent quality

showing that the Swedish standard piston sampler in normal

cases is adequate for routine sampling of soft clays (Larsson et

al., 2012). The main testing programme was performed on

samples taken with the new large diameter sampler.

CPTs and static and cyclic full-flow penetration tests with a

T-bar penetrometer were carried out at each test site. The CPTs

were performed according to the European standard (ISO 2012)

with higher demands for accuracy corresponding to the

recommendations by the Swedish Geotechnical Society for soft

clays (SGF 1993). The T-bar tests were performed using

equipment with recommended dimensions and according to

recommended practice (DeJong et al. 2010). Cyclic T-bar tests

were performed at all levels where sampling had been

performed and the cycling was made over the same 1 m depth

interval. The static phase of the T-bar tests was normally

continued one or a few metres below the deepest cycling level

The laboratory testing involved classification tests of basic

geotechnical properties, CRS-oedometer tests and active static

and cyclic triaxial tests. The classification tests comprised the

normal Swedish routine tests of bulk density, natural water

content, liquid limit and undrained and remoulded shear

strength, the last three determinations being made with the

Swedish fall cone test (ISO 2004). They also comprised

additional tests of plasticity limit, organic content through

analyses of organic carbon, clay content through sedimentation

tests, pH in the soils by use of electrodes and resistivity by use

of a so-called Soil-box (Camitz 1980).

The triaxial tests were performed on specimens that were

first anisotropically consolidated for about 80% of the estimated

preconsolidation stresses in both vertical and horizontal

directions, giving an overconsolidation ratio of 1.3. An

overconsolidation ratio of about 1.3 or slightly lower is typical

for soft clays in Sweden. In tests with higher overconsolidation

ratios, the specimens were then unloaded to the estimated stress

conditions after a corresponding unloading. The consolidation

process was usually completed within 24 hours. The static

undrained active tests were then performed at a rate of

compression of 0,01 mm/min (approximately 0,6%/h), which is

the normal testing rate in undrained tests on clay used at SGI.

Cyclic triaxial tests were performed with both stress-

controlled and strain-controlled cyclic loading. The stress-

controlled cyclic tests were performed as undrained

compression triaxial tests with an initial static shear stress state

corresponding to a factor of safety of 1.3, and an additional

cyclic stress oscillating around this initial stress state. The tests

were performed with different sizes of the cyclic stress

components. The specimens for the strain-controlled cyclic tests

were consolidated in the same way as those for the stress

controlled tests and started at the same initial static shear stress

conditions. The strain-controlled cyclic tests were performed

with two levels of strain; up to the failure strain at static loading

and up to two times this strain.

The cyclic loading was for most part performed with a

frequency of 1Hz, but some tests were also performed at slower

rates (lower frequencies) to study the influence of frequency.

3 RESULTS

T-bar testing was tried out with the main purpose of testing

the rate of shear strength degradation during cyclic tests. The

results have led to new interpretation methods for Swedish clays

similar to those used for CPT-tests. New correlations for

interpretation of remoulded shear strength and sensitivity have

also been brought forward. However, the measuring accuracy of

the equipment was found to be insufficient for accurate

determinations in the soft sensitive Swedish clays where the

remoulded shear strength often is very low (Åhnberg and

Larsson 2012).

The laboratory investigations together with tests in the field

directly after the samples had been taken showed that the

parameters liquid limit, remoulded shear strength and sensitivity

change with time of storage in the laboratory. This is in

agreement with earlier experience (e.g. Larsson 2011). Since

only a small increase in the remoulded shear strength has a large

effect on the sensitivity in quick clays, it is important that these

properties be determined as soon as possible. However, further

control tests showed that a storage time of up to three months

had little influence on other properties or the behaviour during

static and cyclic strength and deformation testing.

The classification tests in the laboratory largely verified

earlier established correlations between properties found for