1409

Technical Committee 203 /

Comité technique 203

Table 2. Modelling parameters of the SYS Cam-clay model

Elasto-plastic parameters

Minimum value

0.0025

Compression index

λ

Maximum value

0.05

Reference value of

γ

p

for

λ γ

λ

0.0001

Minimum value

0.0015

Swelling index

κ

Maximum value

0.049

Reference value of

γ

p

for

κ

γ

κ

0.01

Critical state constant

M

0.90

Specific volume at q = 0 and p ’= 98.1 kPa on NCL

N

1.785

Poisson’s ratio

0.264

Cohesion (kPa)

8 0

4 ANALYTICAL RESULT

4.1

FEM

Figure 7 shows analytical and test results of lateral response

acceleration and displacement at observation points shown in

Figure 8 (a). The analytical results are largely consistent with

the test results. Figure 8 (b) to (d) shows distributions of

amplitude of lateral response acceleration and maximum

shear strain when the amplitude of lateral response

acceleration is the minimum. In test results, the lateral

response acceleration is amplified at the top and right hand

side slope as shown in Figure 8 (b). Large amplification of

the lateral response acceleration is produced at middle part

of the right hand side slope, where partial catastrophic failure

occurred (see Figure 2 (a)). On the other hand, although the

analysis can describe overall behavior of amplification and

phase lag of lateral response acceleration as shown in Figure

8 (c), that cannot describe localized amplification of lateral

response acceleration at right hand side slope shown in

Figure 8 (b) seen in test. Also, shear strain growth is

prominent at the toe of right hand side slope as shown in

Figure 8 (d), which is inconsistent with a middle part of the

slope where partial catastrophic failure occurred. This

indicates that the used FEM model is applicable to describe

overall behavior of amplification and phase lag of lateral

response acceleration, but the model has problems to solve to

deal with shear strain growth due to localized amplification

of lateral response acceleration.

4.2

MPM

Figure 9 and Figure 10 show processes of distributions of

maximum shear strain and lateral response acceleration

derived from MPM analysis. In one layered model,

analytical results show catastrophic failure at right hand side

slope, but the amount of deformation is overestimated

comparing to test results. In three layered model, final

configuration derived from the analysis is largely consistent

with that of the test. Figure 11 shows time histories of lateral

and vertical response displacement at observation points

displayed in Figure 10 (a) introduced from test and analysis.

Start time and rate of change of displacement derived from

the analysis is largely consistent with that in the test. These

indicate that the MPM analysis can deal with the large

deformation such as slide down although a constitutive law

was modeled up to residual state as shown in Figure 6.

5 CONCLUSION

Seismic behavior of large-scale slope model on the world’s

largest shaking table test was analyzed by FEM and MPM.

The outcomes can be summarized as follows:

1) The same trend of the amplification and phase lag of

response acceleration at the top of slope of one layered slope

model as that seen at the shaking table test could be obtained

by the FEM with GHE-S model together with the multiple

nonlinear spring models. However, the FEM model could

not describe the localized amplification of response

acceleration and shear strain growth at the middle part of the

slope where partial catastrophic failure occurred.

0.000001 0.00001 0.0001 0.001

0.01

0.1

0

0.2

0.4

0.6

0.8

1

0

0.1

0.2

0.3

0.4

0.5

G/G

0

減衰

, h

実験値

解析値

Model

Test

h

0.000001 0.00001 0.0001 0.001

0.01

0.1

0

0.2

0.4

0.6

0.8

1

0

0.1

0.2

0.3

0.4

0.5

G/G

0

減衰

, h

実験値

解析値

Model

Test

h

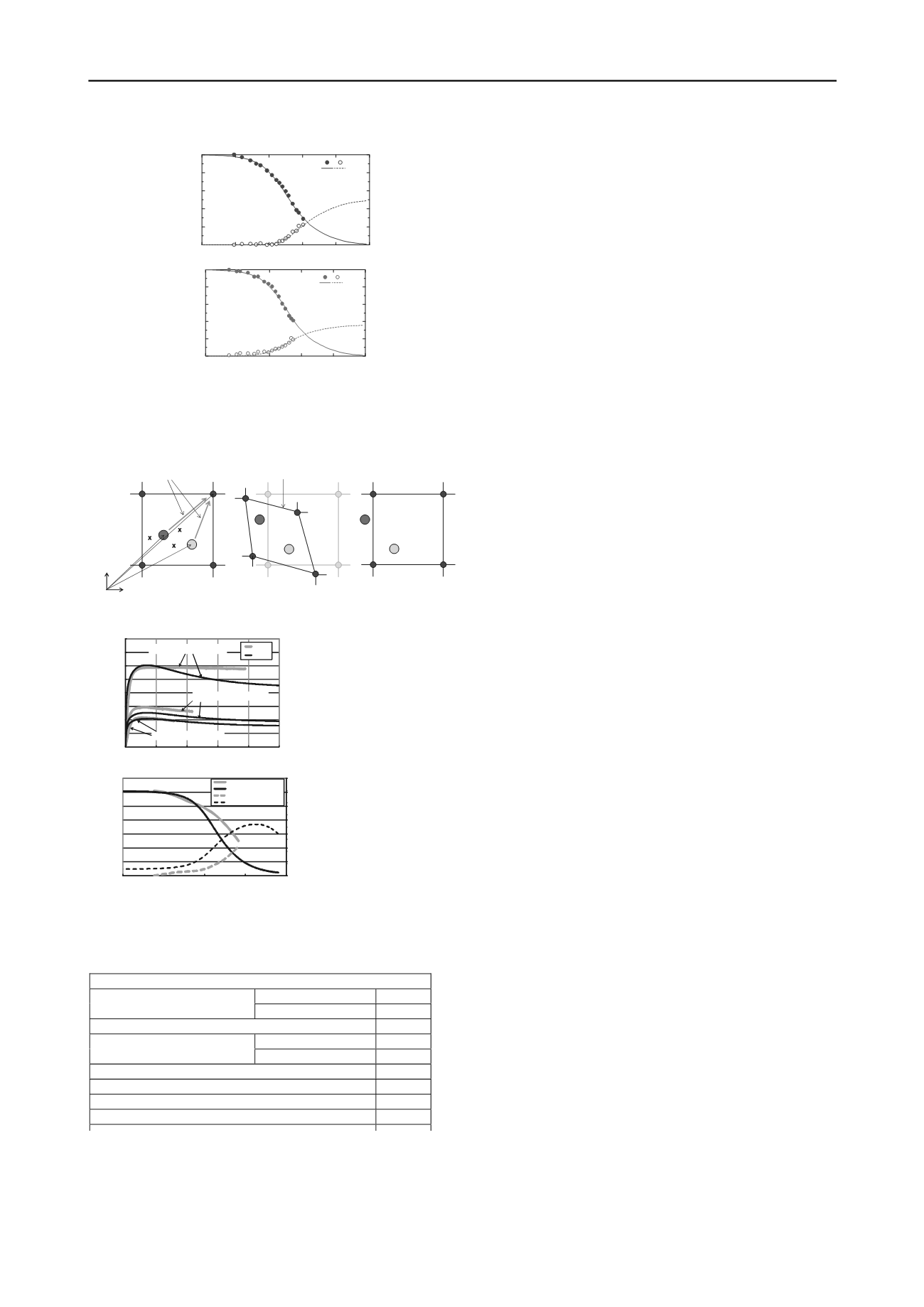

(a) General part (b) Reinforced part

Figure 4. Results of investigation to determine the stress-strain

characteristics of a material specimen under cyclic tri-axial tests using the

GHE-S model

y

x

x

i

x

p1

x

p2

(a)Formerstage

(b)Conventionstage

(c)Latterstage

Transfer physical values of particles

to nodes of background mesh

Calculate strain of background mesh

usingconservativeFEM approach

Mesh is reset to the initial configuration,

whiletheparticlekeepsthe position.

Figure 5. Analysis flow of the MPM

0.0

20.0

40.0

60.0

80.0

100.0

120.0

140.0

160.0

0.0

2.0

4.0

6.0

8.0

10.0

D

eviatoric

stress

(kP

a)

Axialstrain (%)

Test

Model

Confining pressure= 50kPa

Confining pressure=5kPa

Confiningpressure =10kPa

0

5

10

15

20

25

30

35

40

0

10

20

30

40

50

60

70

0.0001

0.0010

0.0100

0.1000

1.0000

D

am

ping

ratio

h

(%

)

S

hearm

odulus

G

(M

N

/m

2

)

Deviatoricstrain (%)

Experiment (shear modulus)

Analysis (shearmodulus)

Experiment (damping ratio)

Analysis (damping ratio)

Confiningpressure= 10kPa

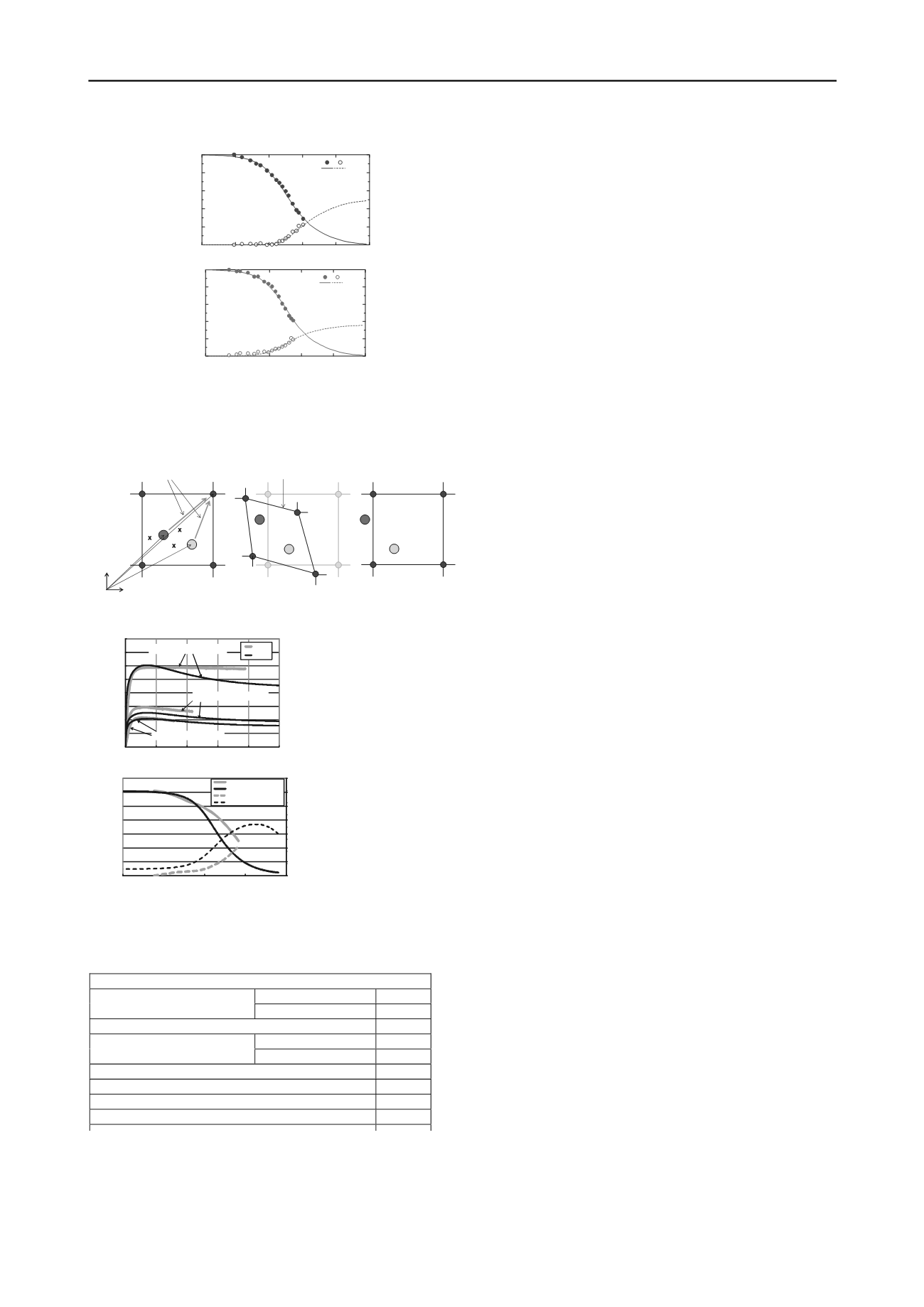

Figure 6. Results of investigation to determine the stress-strain

characteristics of a material specimen under tri-axial compression tests and

cyclic tri-axial tests using the SYS Cam-clay model

2) The similar failure patterns of one and three layered slope

models to that seen at the shaking table test could be obtained

by the MPM with the SYS Cam-clay model. However, the

MPM analysis could not produce good agreements in the one

layered slope model regarding the amount of deformation,

which should be improved in the future work.

3) Consequently, it is considered that the FEM analysis is

appreciate for a slope with large amplification of response

acceleration and the MPM analysis is appreciate for a slope

with a weak layer as analytical tools for assessing seismic

safety of slopes. However, both models should be improved

to evaluate seismic behavior of slopes more accurately.