1400

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

10

-4

10

-3

10

-2

10

-1

1

0.0

0.2

0.4

0.6

0.8

1.0

ACL (this study)

Location #1 (

0

~ 11 - 89 kPa)

Location #2 (

0

~ 11 - 106 kPa)

Zekkos et al. 2008 (

0

< 125 kPa)

100% material < 20 mm

62-76% material < 20 mm

8-25% material < 20 mm

G

/

G

max

Shearing Strain (%)

Figure 2. Modulus reduction curves of MSW (

Zekkos et al.

).

The paper by

Liao et al.

(USA) provides very useful

laboratory test data on the ‘Normalized shear modulus of

compacted gravel’ used for fills. Resonant Column and

Torsional Shear (RCTS) tests were performed on large diameter

specimens of poorly graded (PA) gravel and well-graded (WA)

sandy gravel, both scalped at 19 mm particle size. The curves

for the WA and PA samples (Fig. 3) fall in the ranges suggested

by Seed et al. (1986) and Rollins et al. (1998) respectively, and

are quite consistent with the stress-dependent curves suggested

by Menq (2003) on the basis of the modified hyperbolic model

formulated by Darendeli (2001). Once again, it is expected that

similar considerations about the dependency on grading and

stress state would hold for the damping-strain curves.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0.0001

0.001

0.01

0.1

1

Cyclic Shear Strain,

(%)

G/G

max

52, 207, 414, 827 kPa; C

u

= 150 (Menq, 2003)

WA (414 kPa)

PA (52 kPa)

WA (52 kPa)

WA (207 kPa)

WA (827 kPa)

PA (207 kPa)

52, 207 kPa; C

u

= 2.1

(Menq, 2003)

Figure 3. Modulus reduction curves of compacted gravels (

Liao et al.

)

.

Ray & Szilvágyi

(Hungary), authors of the paper ‘Measuring

and modeling the dynamic behavior of Danube Sands’, report

and discuss results obtained by a RCTS device on hollow

pluviated specimens of a typical alluvial sand. The equipment,

originally developed by the first author in USA (Ray & Woods,

1987), was updated in Győr University in order to be capable of

loading at higher torques and measuring wider strain ranges,

under non-isotropic confining stresses and irregular cyclic shear

loads. The Authors mention, although not showing the

comparisons, that such data were satisfactorily interpreted by

the Ramberg-Osgood model with extended Masing criteria.

Sas et al

(Poland) investigate ‘The behaviour of natural

cohesive soils under dynamic excitations’, by RC tests on

natural shallow samples of silty sand, subjected to stepwise

consolidation stages. The normalized shear modulus-strain

curves, however, appear excessively non-linear for some of the

confining stress levels: this may be due to several experimental

factors, including strain measurement resolution and/or effects

of the consolidation procedure followed.

3 MEASUREMENT AND MODELLING OF CYCLIC

DEGRADATION, STRENGTH AND LIQUEFACTION

3.1

Clean sands

Bolouri Bazaz & Bolouri Bazaz

(Iran) present ‘An experimental

approach to evaluate shear modulus and damping ratio of

granular material’, a Standard Leighton Buzzard sand. Loose

and dense dry specimens were prepared by air-pluviation in a

cubic Biaxial Testing (BT) device, able to apply independent

variations of horizontal principal stresses by hydraulic actuators.

Repeated sequences of cyclic loads with increasing peak stress

ratios, R

max

, showed that both dense and loose sand underwent

progressive densification with the number of cycles. The stress-

strain behaviour was featured by a kind of ‘elastic shakedown’,

i.e. closed loops corresponding to steady shear modulus and

damping ratio approaching zero (Fig. 4). At the highest stress

ratio, soil behaviour turned to softening and dilatant, eventually

leading to a ‘run away’ failure. The results encourage to an

interpretation in terms of hardening plasticity models.

0 10 20 30 40 50 60 70 80 90 100

No. of cycles

0

10

20

30

40

50

60

70

80

Shear modulus (GPa)

Test No.: D-290

R =4

R =4.33

max

max

0 10 20 30 40 50 60 70 80 90 100

No. of cycles

0

10

20

30

40

50

Damping ratio (%)

Test No.: D-290

R = 4

max

Figure 4. Cyclic evolution of modulus and damping for dry dense sand

(

Bazaz et al.

).

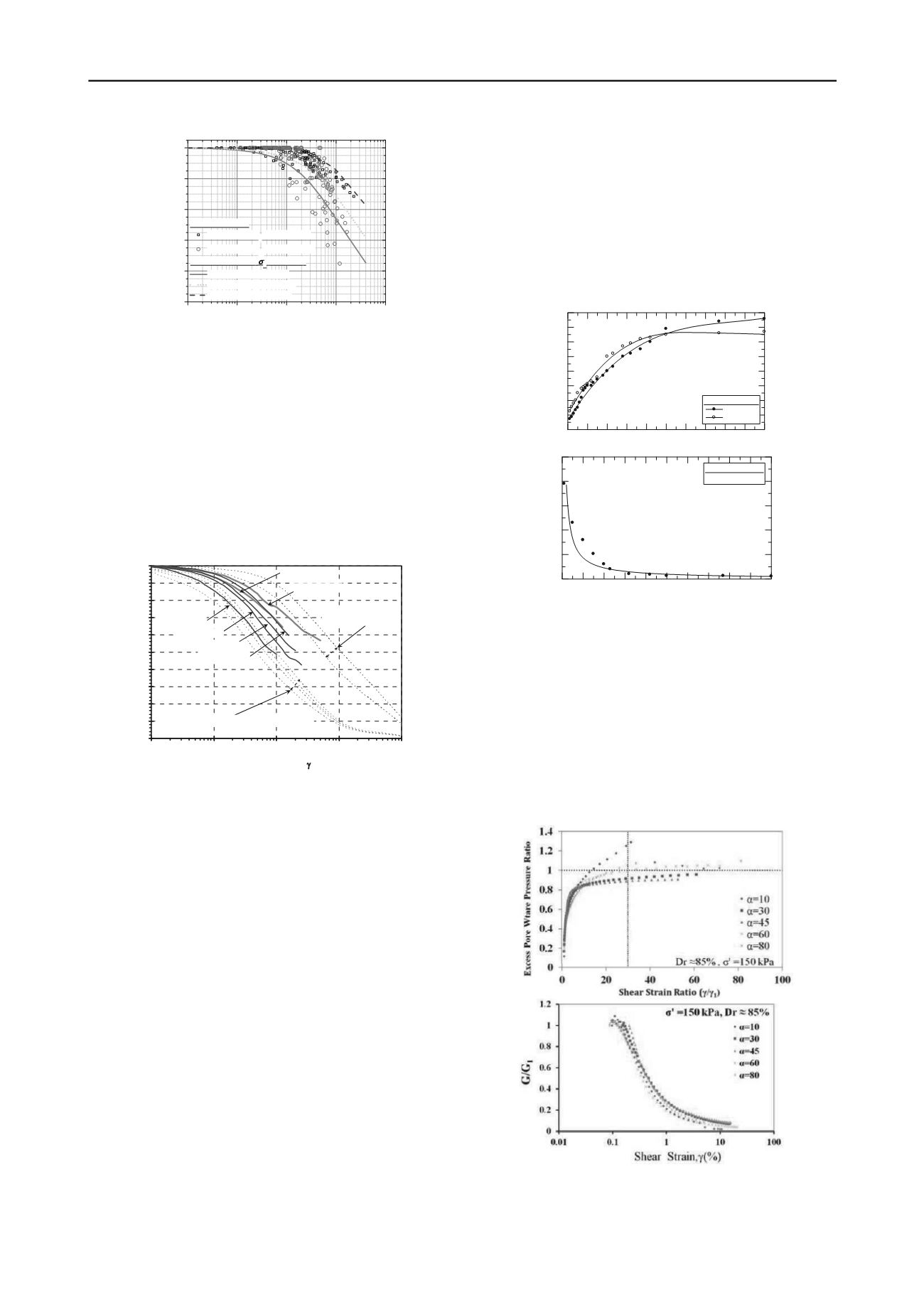

A further interesting contribution from Iran is by

Jafarzadeh

& Zamanian

, investigating the ‘Effect of stress anisotropy on

cyclic behavior of dense sand with dynamic Hollow Cylinder

apparatus’ (HC). Wet tamped specimens of uniform Babolsar

sand were saturated and isotropically consolidated at the same

effective stress, then subjected to constant amplitude shear loads

corresponding to different ratios between torsional shear and

deviator stress, i.e. to different degrees of stress-induced

anisotropy. Results show that the angle

, representing stress

anisotropy, does affect the excess pore water pressure ratio (Fig.

5a), but has no significant influence on the strain dependency of

shear modulus (Fig. 5b) and damping ratio.

(a)

(b)

Figure 5. Effects of stress anisotropy on pore water pressure (a) and

shear modulus (b) for saturated dense sand (

Jafarzadeh & Zamanian

).

Another study on the effects of loading pattern on cyclic

behaviour of clean sands is provided by

Coelho et al.

(Portugal-