786

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

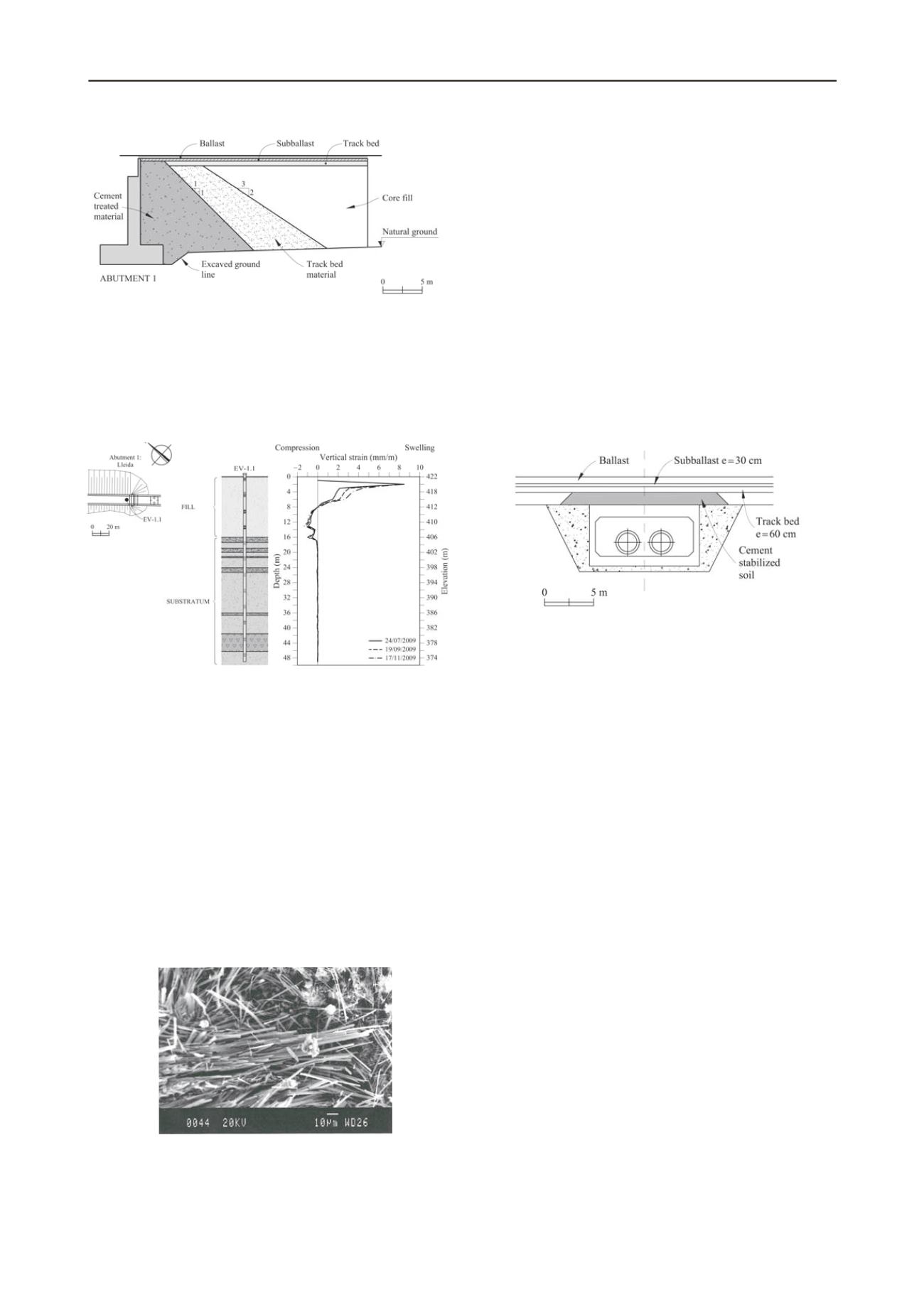

Figure 1. Design of the embankment

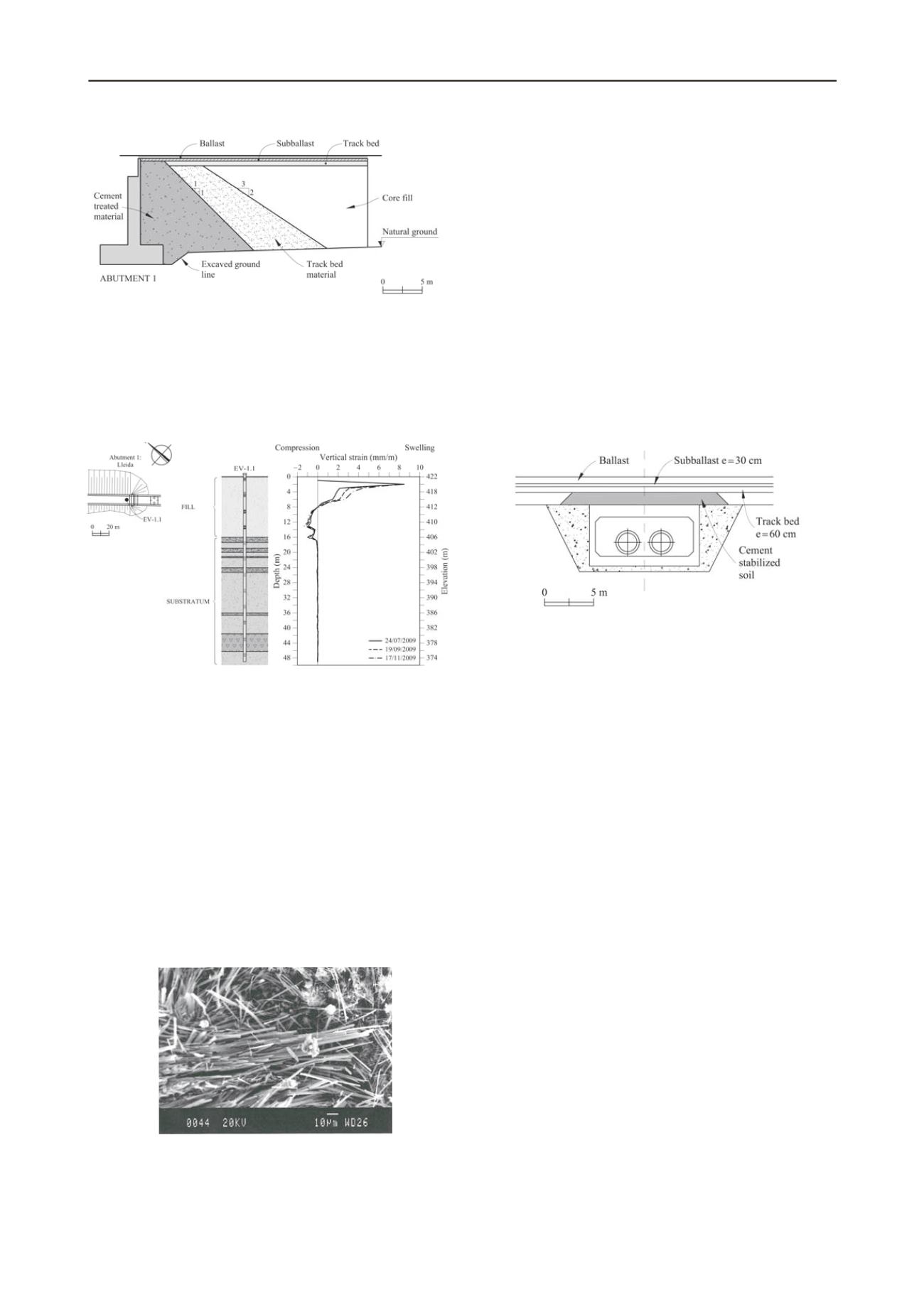

Inclinometers installed in boreholes indicated that swelling

deformations occur not only in the vertical direction, but also in

the horizontal direction. Monitoring of topographic marks

installed on the surface of the embankments confirmed that a

volumetric swelling was deforming the embankments. The

distribution of displacements along the embankment axis agrees

with the intensity of the jet-grouting treatment.

Figure 2. Vertical strains measured by sliding micrometer EV-1.1

Ettringite and thaumasite crystals were found in all the

samples of embankment material, recovered from boreholes,

that were analyzed by means of X-ray diffraction (XRD) and

scanning electron microscope with an energy dispersive

spectrometer (SEM-EDS) (Fig. 3). The combination of

sulphates from the soil, alumina and silica released from clay

minerals because of the alkaline environment, calcium from

cement components, present in the transition wedges and in the

jet-grouting treatment, and also from gypsum, carbonates

released from calcite and the availability of water from rainfall

leads to the formation of ettringite and thaumasite. The

formation of thaumasite and ettringite is essentially unlimited

because of the availability of the necessary components for its

formation in the embankments. It was concluded that

deformations in the embankments will proceed for a long time if

no remedial measures were carried out.

Figure 3. Ettringite needles and thaumasite flat crystals found in a tested

sample from Pallaressos embankments

A finite element model of embankment swelling was

developed to calculate the swelling loads against the bridge

abutments and also to estimate the state of stress on the

embankments (Alonso and Ramon, 2012). It was found that a

dangerous state of passive stresses had been developed on the

upper 8-10 m of the embankment. A total force against the

bridge abutments of 2.32MN/m, induced by swelling of

embankments, was calculated.

3 SOIL TREATMENT OVER UNDERPASS

3.1

Introduction

The second case concerns a rigid reinforced concrete caisson

structure 11.2 m wide and 6.25 m high, built under the railway

tracks to allow for the crossing of an aqueduct. The structure

was capped by a layer of cement treated soil, 1.5 m thick.

Above, base and ballast layers complete the layered system

supporting the railway tracks. Figure 4 shows a cross section of

the caisson. Material for the fill came from a nearby cut in the

same railway line. The exposed slopes showed the soil

formation: a Tertiary red claystone with abundant gypsum

veins.

Figure 4. Cross section of the caisson of the underpass.

Periodic track levelling detected a progressive heave of the

tracks above the caisson. The maximum accumulated vertical

displacement measured in July 2011 was about 12 cm.

3.2

Field data

Topographic levelling of the caisson didn’t show any vertical

displacement of the structure. This indicated that the vertical

displacements measured at the rail tracks were a result of the

behaviour of the material placed above the concrete caisson. A

convex surface, centred in the caisson axis, was also visible in

the field (Figure 5). In addition, the thickness of the ballast layer

was noticeably lower in the bulging area, because of the

necessary periodic ballast thickness correction. Two high

precision (± 0.003 mm/m) vertical continuous extensometers

(SL-1 and SL-2), 10 m long, were installed in boreholes located

in the caisson backfill material, close to the concrete structure.

Both extensometers recorded the development of vertical strains

at both backfills within the upper 4 m (Figure 6 and Figure 7).

A maximum heave rate of 1.33 mm/month was measured

between 17

th

, February 2012 and 19

th

, April 2012. A heave rate

of 0.91 mm/month was recorded during the same period at the

same depths in the other backfill (SL-2).

Continuous cores and undisturbed samples were recovered

from boreholes performed for the installation of extensometers.

A few SPT tests were also performed in borings SL-1 and SL-2

at depths of 0.6-2.50 m. The recorded values (N = 46, 25, 39,

26, 42) reveal a compact material although the presence of

gravels complicate the interpretation.

A borehole 2.8 m long

was also drilled above the caisson, centred along the axis of

the caisson. A value N = 20 was measured in this location at

a depth of 1.30-1.90 m. Interestingly, t

he material recovered

from boreholes at depths varying from 1.2 to 2.75 m was found

to be soft and wet or very wet. At those depths the existence of

a heavily weathered material with presence of a mixture of

cement and some sand was also observed.