790

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

analysis often requires excessive computation resources (both

storage and time). During tunnel construction, a volume of soil

squeezing into the opening creates deformations around and

above the tunnel, which cannot be simulated directly in 2D

finite element analysis. Hence, various methods have been

proposed to take account of the stress and strain changes ahead

of the tunnel face when adopting 2D plane strain analyses to

simulate tunnel construction (Karakus 2007).

In this study, a two-dimensional finite element multistep

simulation model for shield-driven tunnel excavation is

presented. The model takes into account all relevant

components of the construction process as separate components

in model (including: soil and ground water, tunnel lining and

tail void grouting). The buildings were simulated by an elastic

beam at the surface of the models. Each surface beam has an

equivalent moment of inertia (I) and thickness (t) representing

the associate building. The surrounding soil above the ground

water level was discretized by 4-node first order fully integrated

continuum elements (CPE4) and the tunnel liner and elastic

beams (representing buildings) simulated as 2-node linear

Timoshenko beam elements. The under groundwater soil and

the grout material are modelled as saturated porous media using

pore pressure elements (CPE4P). The time dependence of the

grout material characteristics due to hydration is modelled in a

simplified manner by employing a time-dependent Young’s

modulus and Poisson’s ratio. The soil behavior is assumed to be

governed by an elastic perfectly-plastic constitutive relation

based on the Mohr–Coulomb criterion with a non-associative

flow rule.

The behavior of lining concrete is assumed to be linearly

elastic with properties which are usual for C45/55 concrete

(E=36000MPa, υ=0.2). For considering decrease of rigidity at

segment joints, a transfer ratio of bending moment is

introduced. This aspect is transferred to numerical analyses with

Correction of the elastic modulus of the ring, according to

modification factor

ζ=0.3

:

Mpa

E

E

CLS

25200

36000

)3.01(

) 1(

c

(1)

Where

E

c

is the virtual modulus of the ring and

E

cls

is the

concrete modulus. During the parametric studies, the geological

features were considered unchanged and similar to the Tabriz

metro line2 site conditions that described later. The ground

water ingress into the tunnels during construction phase is not

considered in this study. The excavation and construction of the

tunnel are simulated in 5 stages. In the first phase, the geostatic

equilibrium achieved and in second step the building is

constructed, but the corresponding deformations are not taken

into account in further steps. In excavation step inside the tunnel

the soil is excavated by de-activating the corresponding volume

elements and allows that the tunnel border moves radialy

accordance with overcutting value. In next step, the lining

installed and grout elements are activated in the fluid state

simultaneous with application of the injection pressure. After

installing step the injection pressure removed and the

mechanical characteristic of grout elements changed to

hardened one. Based on similar projects, under good operative

conditions, time duration of excavation step considered 5400

seconds and the time of lining ring erection considered 900s.

Boundary conditions, element types and mesh density of the

numerical models were selected based on several sensitivity

analyses as not to influence the results. The finite-element mesh

extends to a depth of two times the tunnel diameter (

D

) below

the tunnel spring line and laterally to a distance of 6

D

from the

tunnel centerline. The locations of the lateral and bottom

boundaries are selected so that the presence of the artificial

boundaries does not significantly influence the stress-strain-pore

pressure field in the domain. The modelled domain was 120 m

in width and 45 m in depth, consisting approximately 10,000

nodes and 2,000 elements.

3 CHARACTERISTICS OF TABRIZ METRO LINE 2

Tabriz with 160

km

2

area and the population about 1,600,000 is

one of most populated and important cities in northwestern of

Iran. TURL2 about 22 km in length will connect eastern part of

the city to its western part. This line comprises a single tunnel

which has been constructed using one earth pressure balance

EPB-TBM with a cutting-wheel diameter of 9.49 m and a shield

with external diameter of 9.46 m in front of shield that induce

overcut equal to 1.5 cm in each side of shield. For lining of the

tunnel, 35 cm-thick precast concrete segments with a length of

150 cm are installed just behind the shield.

Geologically, in central part of the route, based on conducted

studies in the corridor of TURL2, soil is mainly silt with low

plasticity (ML) and silty sand (SM) and water table is about 9m

deep. Geotechnical specifications used for soil layers of the

models are presented in Table1. Mechanical properties of tunnel

liner and tail void grout, utilized in the numerical simulations,

are summarized in Table2.

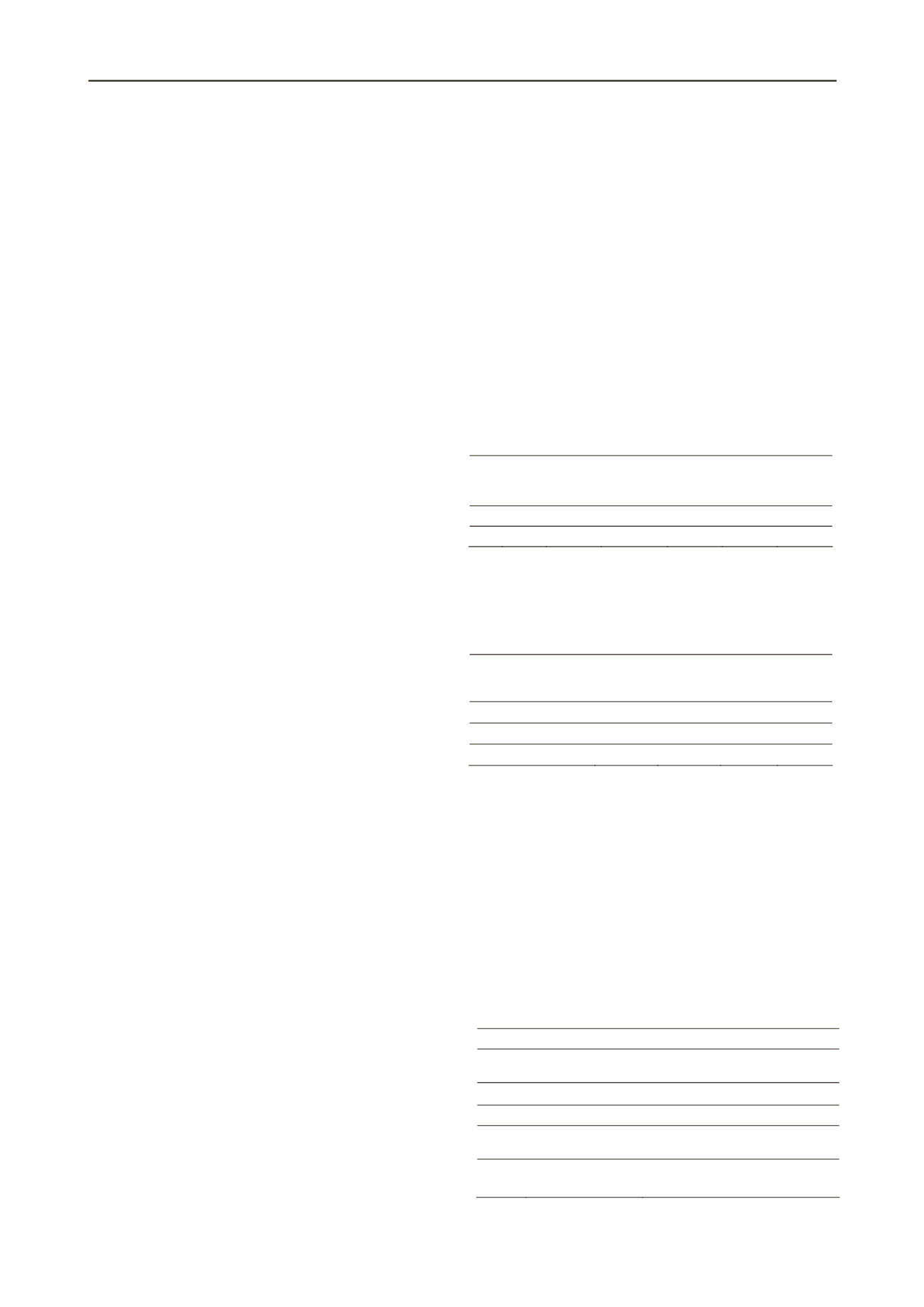

Table1. Geotechnical specifications used for soil layers of the model

ID

Dry

density

(KN/m

3

)

Wet

density

(KN/m

3

)

Elastic

modulus

(kPa)

Cohesion

(kPa)

Internal

friction

angle

Dialation

angle

SM 16.25

20

40000

7

34

3

ML

16.8

20.35

25000

17

25

0

In general the grout pressure value considered 0.5 bar more

than applied face support pressure. Therefore, the required face

pressure for each model calculated and in accordance with

calculated value, the grout pressure adopted for each model.

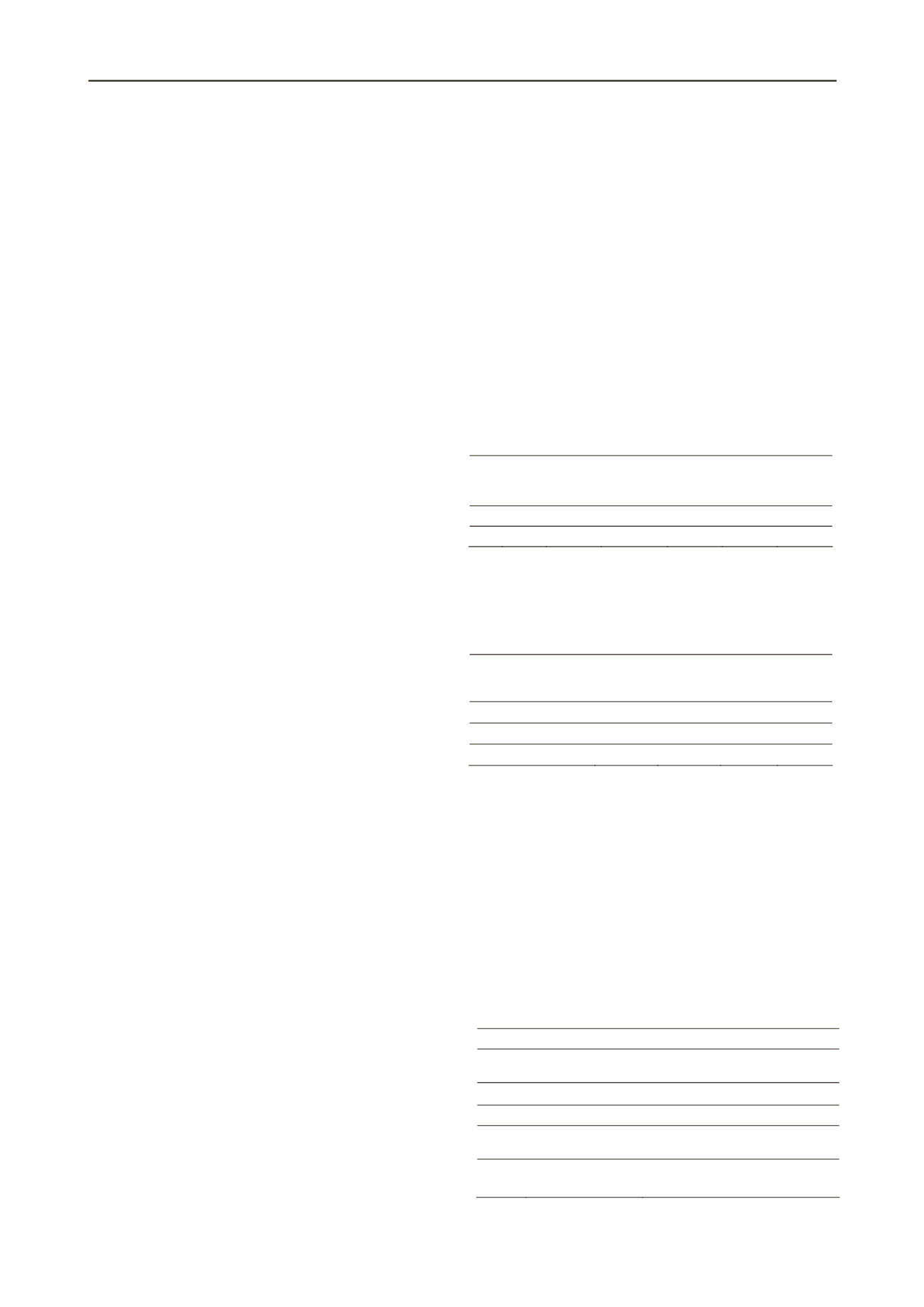

Table 2. Material properties used in numerical simulations

Material

Unit

weight

(KN/m3)

Compressive

strength

(MPa)

Elastic

modulus

(MPa)

Poisson

ratio

Tunnel liner concrete

25

40

25200

0.2

Tail void grout (fluid)

18

0

5

0.47

Tail void grout (hardened)

18

3

20

0.3

4 PARAMETRIC STUDIES

The effects of building’s geometry, position and weight on

lining loads were studied. Four types of 3, 5, 8 and 10 story

buildings above the center of the tunnel were modelled to apply

the effect of surface buildings weight. For each floor, 10 kN/m2

was considered as weight load. In addition study of geometry

effect on the model turned out to be possible through modelling

of buildings with different width and different distance from

tunnel center. The lining stresses of tunnel bored in coarse

grained sand overlain by soft soil layer are compared to induced

stresses in lining of tunnel in a homogeneous sandy soil. The

values of above parameters have been selected based on Tabriz

metro line 2 data and its urban conditions, as introduced in

Table 3.

Table 3. Factors and their values used in parametric studies

Parameter

Description

Values

Z

0

Tunnel center depth

13.8m ,18.4m, and 23m (according to

C/D=1, C/D=1.5 and C/D=2 respectively)

W

Building weight

30, 50, 80 and 100 (KN/m

2

)

B

Buildings width

10, 15, 20, 30 and 40m

E

Distance between tunnel

and building centers

0, 10, 20, 30 and 40m

L

Edge to edge distance

between buildings

15 m, 20 m, 30m, 40m (corresponding

to width of the streets along the route)