782

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

each element behavior along its individual streamline, the

method utilizes topological ordering based on upstream

weighting, and calculates the cumulative information within the

flow direction. The use of this method allows consideration of

various aspects of soil behavior, including rate effect, strain

softening and anisotropy. General agreement between the

results of

this method and the numerical “re

-meshing

”

method

of Zhou and Randolph (2007, 2009) exists. It should be noted

that the upstream weighting method has the engineering

advantage of being an upper-bound solution, and thus

necessarily conservative for evaluating strength values from

penetration resistance.

3 SOIL STRENGTH

The soil strength might be modified due to different soil effects.

The formulation of the undrained shear strength in this work

describes shear rate strengthening,

f

r

, strength degradation due

to accumulation of shear strains,

f

ss

, and due to the influence of

large rotations in anisotropic soils,

f

an

. The effect of these three

factors on the undrained shear strength is given by:

0

u an ss r

u

s f f f

s

(1)

where

s

u

is the undrained shear strength and

s

u0

is the reference

(undisturbed) undrained shear strength. The above soil strength

effects were rigorously studied and presented below:

3.1. Strain rate effect:

The strain rate factor used in this work is based on Dayal and

Allen (1975), and is the basis of many other works (e.g.,

Randolph, 2004, Einav and Randolph, 2005, Yafrate and

DeJong, 2007, Klar and Osman, 2008, Klar and Pinkert, 2010,

Zhou and Randolph, 2007&2009), given by:

1,

max

log 1

0

ref

u

u

s

s

(2)

where

is the maximum engineering shear strain

rate

3 1

,

ref

is the reference shear rate associated with

s

u0

(1%/hour for standard CU triaxial test) and

is the soil

viscosity parameter. Yafrate et al. (2009) suggested extracting

directly from the global resistance of two penetration tests at

different penetration rates using the same logarithmic relation as

Eq. 2, applied directly on the velocity. Pinkert (2012) utilized

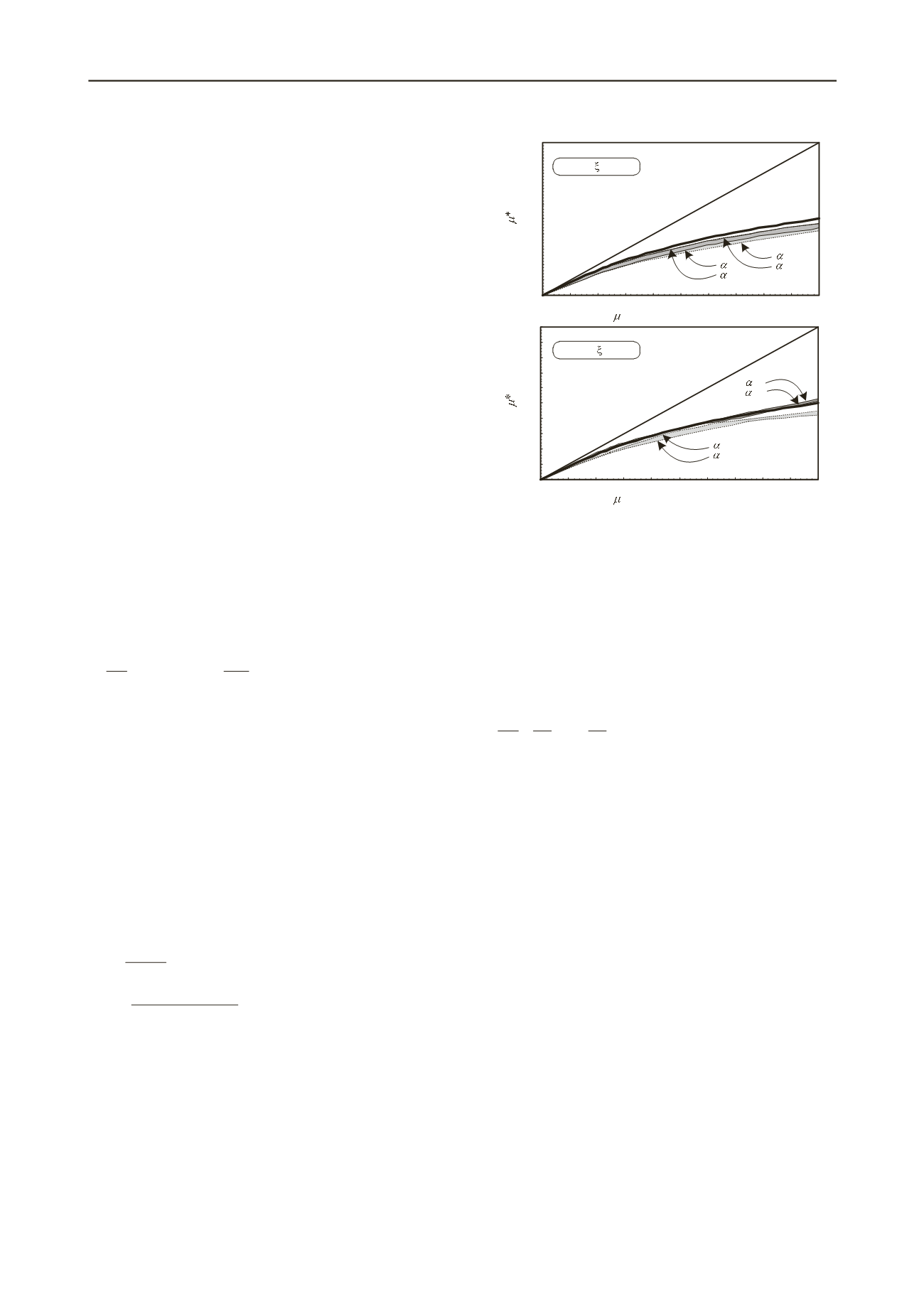

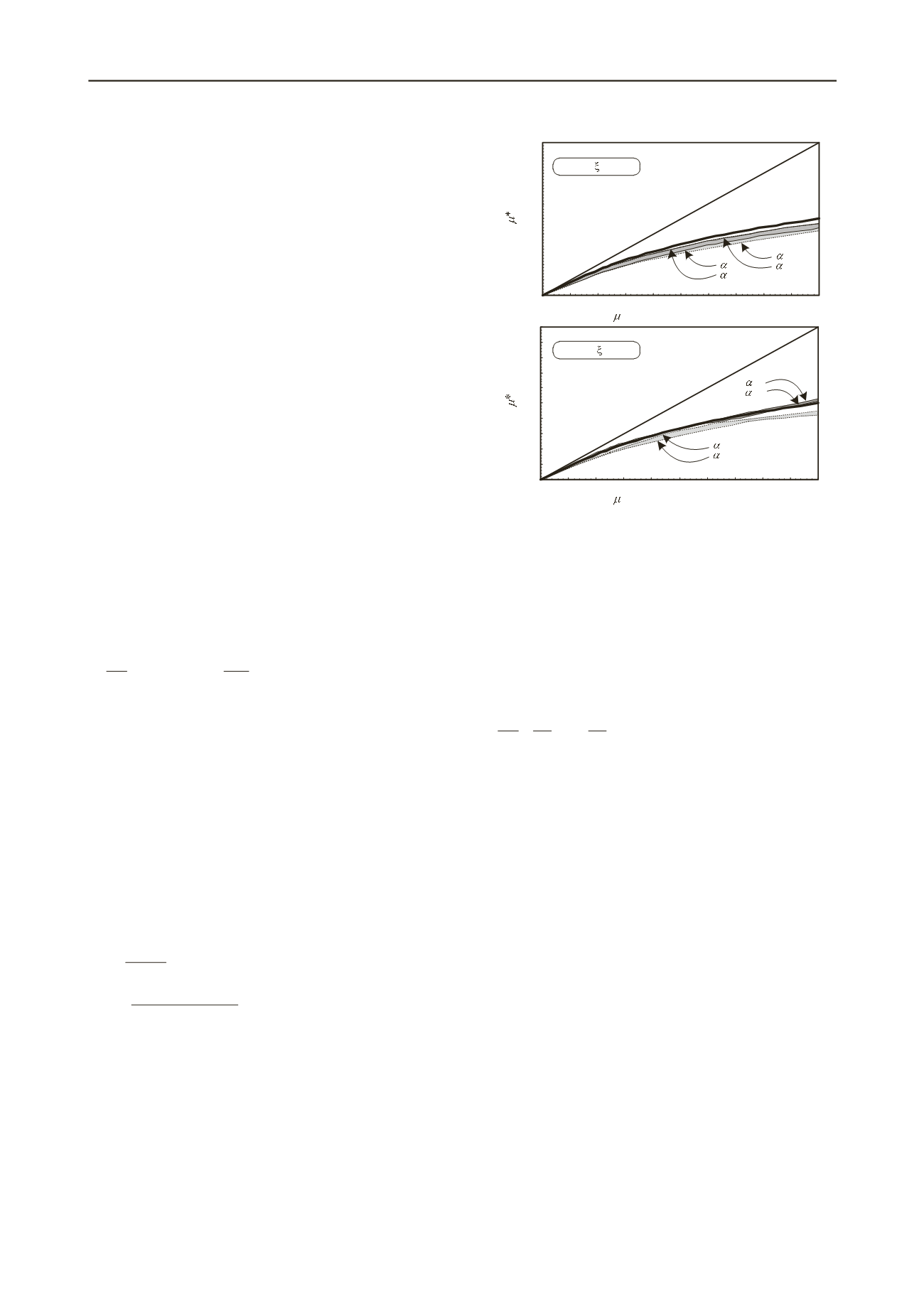

the “upstream weighting” analyses to show that

used in Eq. 2

is not the same parameter which describes the increasing in the

global penetration resistance due to the increase in the

penetration rate,

, as can be shown in Fig. 2.

In addition to the numerical analyses, Pinkert (2012)

developed an algebraic relation between these two parameters,

given by:

2

1

2 1

*

*

*

/ /

/

log

1 /

51

dv dv

qq

(3)

where

q

is the penetration resistance (in stress units),

v

is the

penetration velocity,

d

is the penetrometer diameter, and the

subscripts 1 and 3 denotes two different penetration tests.

=1

=0

Ball

T‐bar

S

T

=20,

95

=10

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

0

0.05

0.1

0.15

0.2

(used in the strength law)

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

0

0.05

0.1

0.15

0.2

(used in the strength law)

Eq. 3

1:1

1:1

Eq. 3

=1

=0

=1

=0

Ball

T‐bar

=1

=0

S

T

=2,

95

=50

Figure 2.

versus

for the all range of friction ratio (0

≤

≤ 1), and

for different softening properties, after Pinkert (2012).

3.2. Strain softening effect

The strain softening factor used in this work was developed by

Pinkert (2012), and may be considered a modification of the

“common” strain softening model used

in all previous works

(e.g., Randolph, 2004, Einav and Randolph, 2005, Yafrate and

DeJong, 2007, Klar and Osman, 2008, Klar and Pinkert, 2010,

Zhou and Randolph, 2007&2009), given by:

95

/ 3

0

1 1 1

e

S

S s

s

T

T

u

u

(4)

where

S

T

is the soil sensitivity (=

s

u0

/s

u,residual

),

is the

cumulative engineering strain rate,

is the amount of

required for 95% remolding and

is a constant.

The

parameter does not exist in all previous (aforementioned)

works. Pinkert (2012) showed that a value of 2/3 for

gives a

good fit to the decay function observed in cyclic penetration

tests, under a wide range of soil sensitivities. Note that the

relation between

95

and

N

95

(the number of cycles required to

achieve 95% degradation in the measured resistance, in a cyclic

penetration test) as presented in Einav and Randolph (2005) is

somewhat inconsistent, since

N

95

is associated with degradation

from the first insertion which cannot truly represent an

undisturbed state (since

does not remain zero at the first

insertion). For that reason, Pinkert (2012) suggested a

theoretical parameter,

N

*

95

, which is related to

N

95

, and thus can

be extracted from field test results. The expression for

evaluating

from cyclic field test results is given by:

2/33/2

3/2

95

*

95

95

5.0

2

2

N

N

p

p

(5)

where

N

95

can be correlated with

S

T

following Yafrate et al.

(2009):

27.0

95

6.9

T

S

N

(6)

and

p

is the average magnitude of shear strain undergone by

soil elements passing through the failure mechanism in

individual penetration, which can be estimated based on values

presented in Zhou and Randolph (2009) for both T-bar and ball:

62.2

log1.1

09.3

log 83.0

,

,

T

ball

p

T

Tbar p

S

S

(7)