736

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

static liquefaction (Aubertin et al. 2002a; James 2009; Azam

and Li, 2010).

The release of tailings following the failure of an

impoundment is the one of the most serious risks associated

with mining and historically has caused numerous fatalities and

enormous environmental damage (ICOLD 2001).

2.2

Waste Rock

Waste rock, the silt to boulder size particles of broken rock

excavated to access ore, is a byproduct of mining. It may be

chemically inert or reactive, depending on the mineral

composition. In any event, it must be stored safely and

indefinitely at a reasonable cost. The grain size distribution of

waste rock generally falls in the range shown on Figure 1. The

gradation of waste rock results in a permeable material with a

relatively high stiffness and frictional strength. In geotechnical

terms, waste rock can be considered as rockfill.

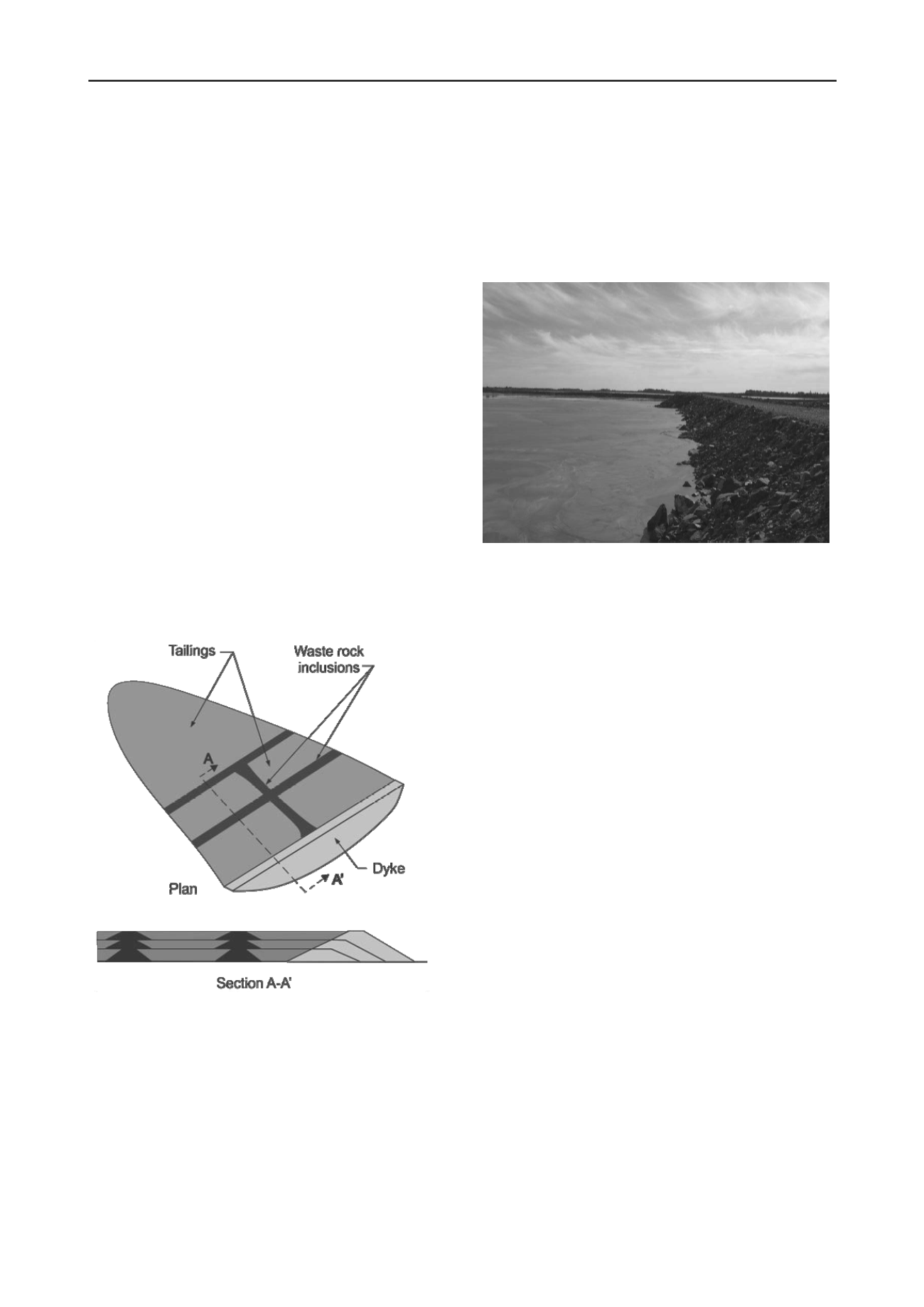

3 WASTE ROCK INCLUSIONS

The construction of a tailings impoundment with waste rock

inclusions would proceed as follows: a) construction of the

starter dyke; b) placement of a thin layer of waste rock on the

bottom and sides of the impoundment; c) placement of waste

rock along pre-designated routes within the impoundment (local

heaps can also be placed – not shown here); d) hydraulic

deposition of tailings. For each stage of raising of the dyke, the

placement of additional waste rock on top of the existing

inclusions is followed by tailings deposition.

The resulting configuration of the impoundment with

inclusions is shown schematically on Fig 2.

Figure 2. Schematic representation of a tailings impoundment with

waste rock inclusions.

The basic premises of the method are that the waste rock being

more permeable and stronger than the tailings would accelerate

drainage and thus consolidation of the tailings, while providing

some physical reinforcement of the tailings. This is somewhat

similar to the use of gravel columns in deposits of soft clay or

silt for consolidation and reinforcement (Adalier et al. 2003).

The expected benefits of waste rock inclusions include

accelerated consolidation and compartmentalization of the

tailings, increased stability of the impoundment, and secure

placement of waste rock in the impoundment, additional waste

management options, and additional closure options.

Two issues which must be addressed are the infiltration of

the tailings into the waste rock and the ability of the tailings to

support the successive stages of waste rock placement. These

are discussed later in this paper.

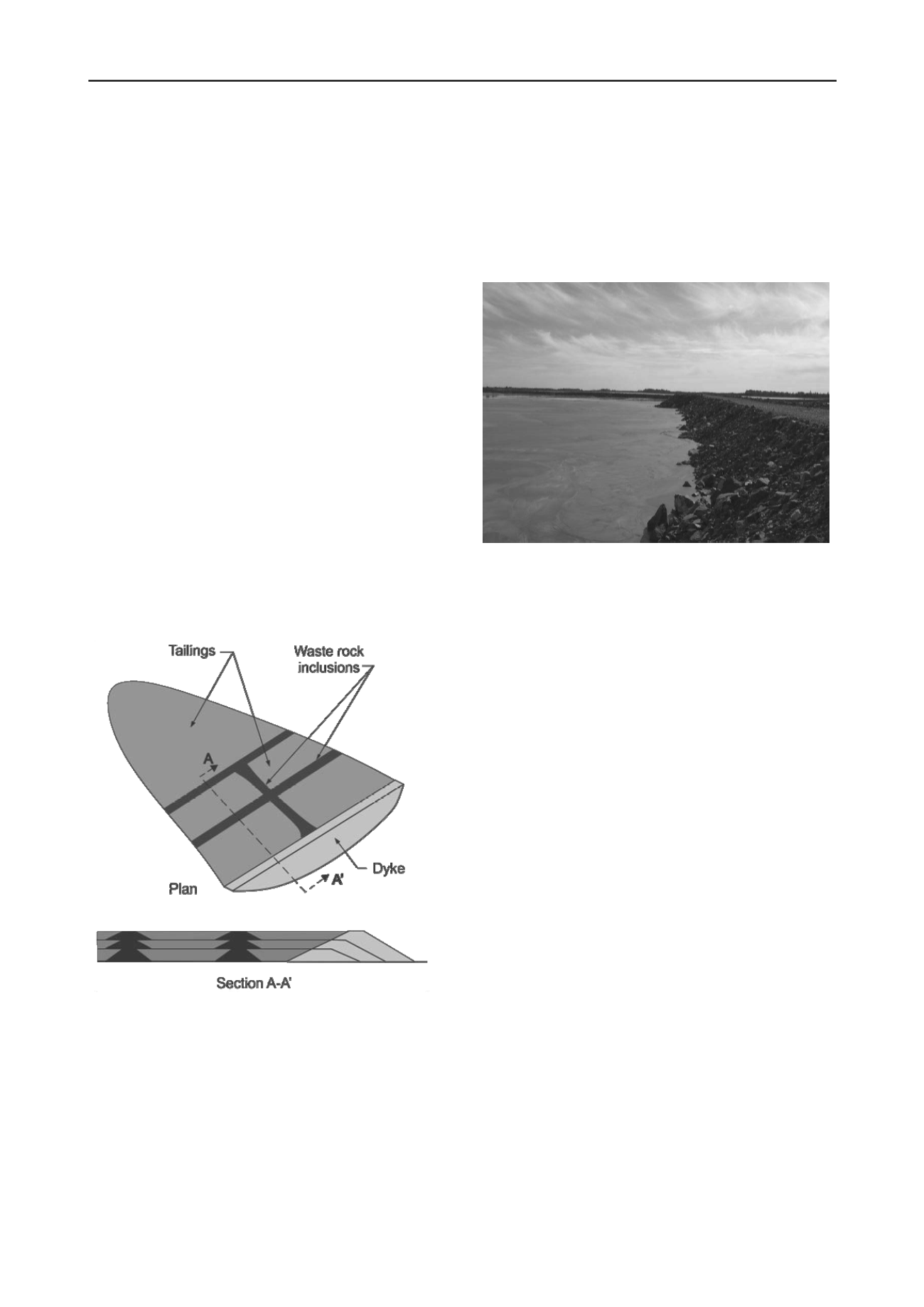

Waste rock inclusions are currently being used at a gold

mine in western Quebec to help manage the tailings and

accelerate their consolidation. Figure 3 is photograph of an

inclusion at the mine. Surveillance and in situ testing of the

performance of these inclusions is ongoing.

Figure 3. A waste rock inclusion in a tailings impoundment at a mine in

western Quebec.

4 WASTE MANGEMENT AND CONSOLIDATION

Depending on the respective volumes of tailings and waste rock

produced, using waste rock inclusions could allow much of the

latter to be placed in the impoundment and eventually

submerged, significantly reducing the potential for AMD and

possibly eliminating the need for a separate disposal facility for

the waste rock. In some instances the reactive waste rock could

be used to form inclusions, which will remain submerged, while

the nonreactive waste rock is stored conventionally in piles.

Tailings could be discharged from conduit on the top of the

inclusions (as is done at the above mentioned mine), as well as

on the crest of the dyke, allowing for a more even distribution

of the tailings within the impoundment. In wide impoundments

this would result in additional volume for storage and more

flexible placement schemes.

The hydraulic conductivity of waste rock allows the

inclusions to act as drains within the tailings, accelerating

consolidation which leads to more rapid strength gain and

liberates more water which may be reused at the site. Parametric

numerical modeling of tailings consolidation with and without

waste rock inclusions by Jaouhar (2012) and Bolduc (2012)

indicates that waste rock inclusions can lead to a significant

increase in the rate of consolidation, depending on the spacing

of the inclusions, the thickness of the deposit, and the hydraulic

conductivity of the tailings. The accelerated rate of

consolidation is due to the reduced length of drainage paths

within the tailings as shown on Figure 4.

There can be some infiltration of the tailings into the waste

rock during placement and consolidation. The grain size

distribution of the waste rock tends to be highly heterogeneous,

in part due to segregation during transportation and placement.

Based on field observations at the site where inclusions have

been installed, many drainage pathways remain viable despite

the infiltration of tailings. Laboratory testing of the effect of

tailings infiltration on the flow through waste rock is currently

underway.

With respect to the stability of the inclusions within the

impoundment, the consolidation of the adjacent drained tailings