735

On the use of waste rock inclusions to improve the performance of tailings

impoundments

Sur l'utilisation d'inclusions de roches stériles pour améliorer la performance des parcs à résidus

miniers

James M., Aubertin M.

Département des génies civil, géologique et des mines, École Polytechnique, Montréal

Bussière B.

Chaire industrielle CRSNG Poly-UQAT Environnement et gestion des rejets miniers, Université du Québec en Abitibi-

Témiscamingue

ABSTRACT: A novel co-disposal method, consisting of the placement of waste rock in tandem with tailings, improves the

environmental and geotechnical performance of surface impoundments. The waste rock is used to create linear inclusions within the

tailings. These inclusions, being more permeable and more rigid than the tailings, improve the performance in several ways, such as

facilitating consolidation of the tailings and augmenting the physical stability of the impoundment. The benefits of this new concept

are being evaluated by means of in situ and laboratory testing, analytical and numerical methods and monitoring at a tailings

impoundment where it is being implemented.

RÉSUMÉ : Une méthode de co-disposition, qui consiste à placer des roches stériles en tandem avec des résidus miniers, améliore la

performance environnementale et géotechnique des parcs à résidus. Les stériles sont alors utilisés pour créer des inclusions linéaires

dans les résidus. Ces inclusions, plus perméables et plus rigides que les résidus, améliorent la réponse de plusieurs façons, en facilitant

par exemple la consolidation des résidus et en augmentant la stabilité physique du parc. Les avantages de ce nouveau concept,

présenté ici, sont évalués au moyen d’essais in situ et en laboratoire, de méthodes analytiques et numériques, et par le surveillance

d’un parc à résidus où il est mis en œuvre.

KEYWORDS: waste rock, tailings, inclusions, co-disposal, consolidation, stability, liquefaction, seismicity.

1 INTRODUCTION

Mining and mineral extraction produce two primary forms of

solid waste: waste rock excavated to reach ore of economic

value and tailings composed of particles of crushed rock from

the milling process.

Generally, waste rock and tailings are stored on the surface

separately, the waste rock in piles and the tailings in

impoundments. The generation of acid mine drainage (AMD),

the leaching of heavy metals, the presence of contaminants

remaining after ore processing, and the physical stability of the

structures formed by these wastes are critical and costly

considerations during operations and after the closure of mining

facilities.

Aubertin et al. (2002a) proposed a co-deposition method that

creates inclusions of permeable, rigid waste rock in deposits of

relatively impermeable, soft tailings. The use of such inclusions

can result in significant improvement in the environmental and

geotechnical performance of the disposal facitlity. This paper

describes the concept and the expected improvements in the

response of the impoundment based on in situ and laboratory

testing, analytical and numerical studies, and observations at a

site where it is currently in use.

2 MINE WASTES

2.1

Tailings

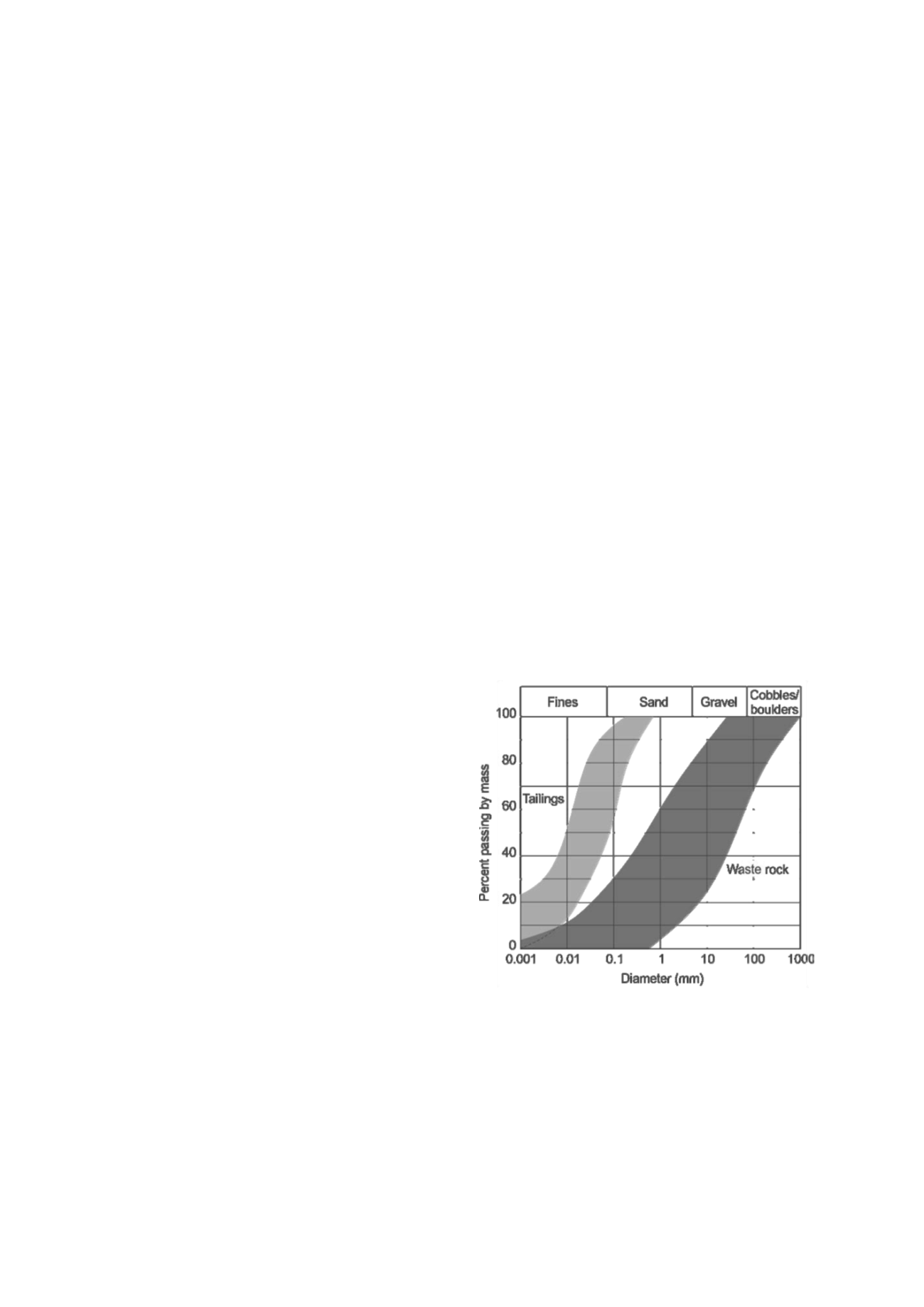

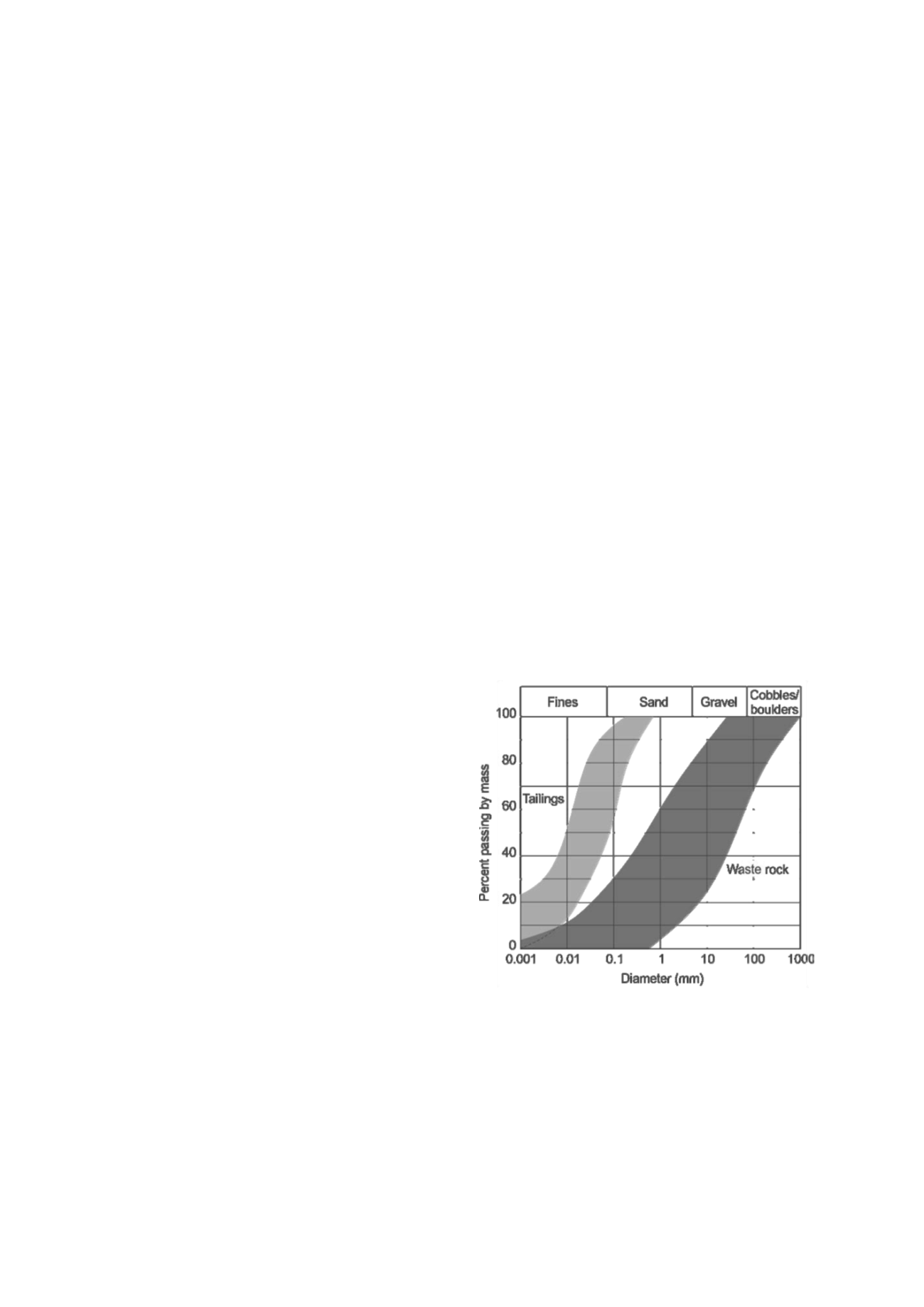

Tailings are typically produced as slurry composed of rock

particles and process water. The particles range in size from

colloids (less than 0.001 mm) to fine sands (> 0.075 mm) with

the silty fraction dominating. The behavior of tailings is

determined by the grain size distribution, water content and

plasticity. Tailings from hard rocks mines tend to be non-plastic

and are the subject of this research. Typically, the grain size

distribution of such tailings lies within the range shown on

Figure 1.

Figure 1. General range of grain size distributions for tailings and waste

rock from hard rock mines (adapted from Gamache-Rochette 2004 and

Bussière 2007).

For most mines, tailings are deposited hydraulically in

impoundments formed by retention dykes and consolidate under

their own weight. The predominance of fine particles results in

low consolidation rates and porewater pressure build up during

filling. For practical reasons, such as waste water storage and to

prevent acid generation, the water level in tailings

impoundments is often kept near the surface. Such a mass of

loose, saturated, cohesionless material is particularly susceptible

to liquefaction. Numerous failures of tailings impoundments

have been associated with seismically-induced liquefaction,

while impoundment failure from other causes often results in