46

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

advanced and the cyclic interface shearing caused by jacking

promoted further shear abrasion.

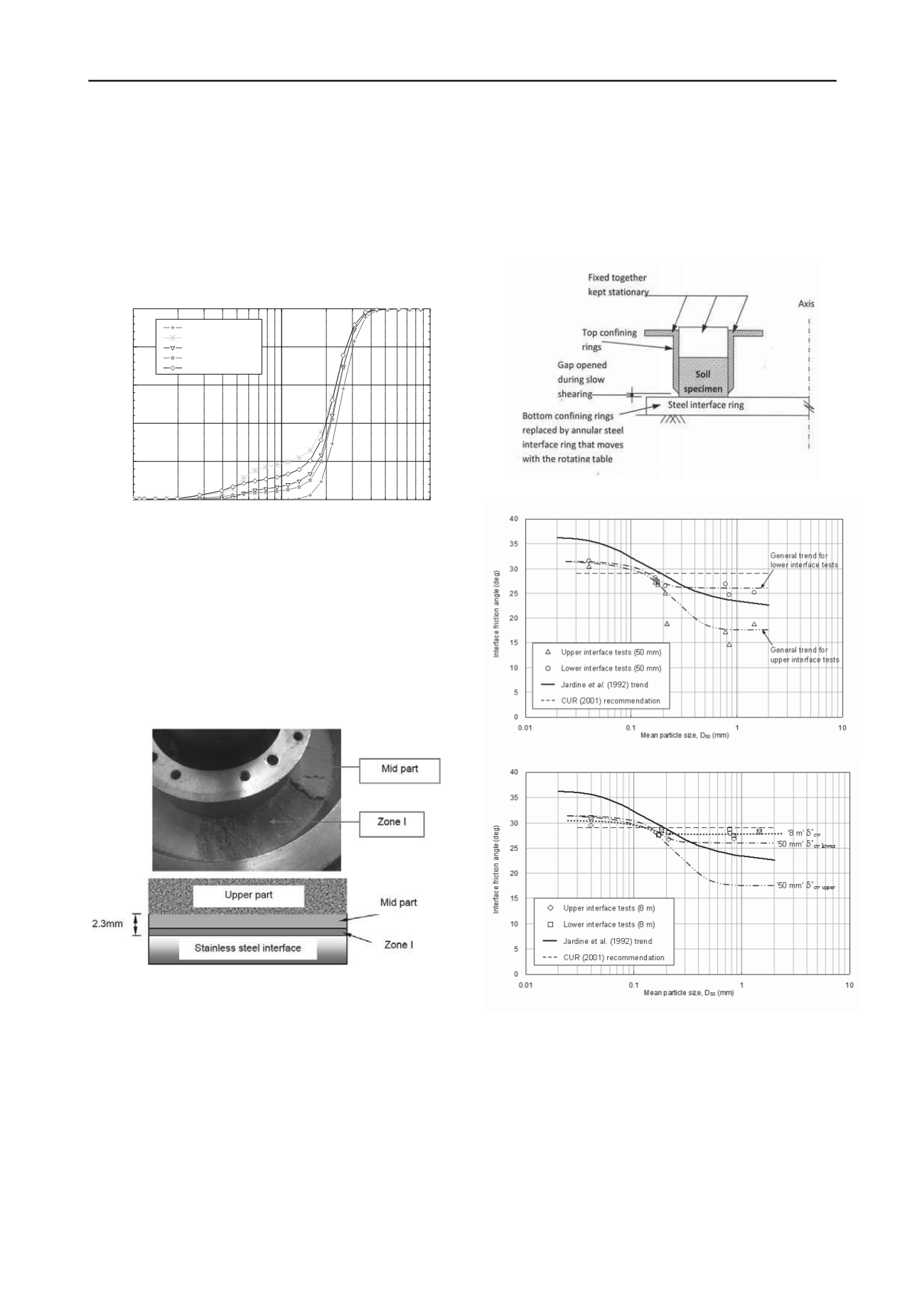

Figure 31 displays the progressively increasing breakage

from the fresh sand through Zones III, II to the interface Zone I,

where about 20% of the sand comprises fragments finer than the

smallest grains present in the parent NE 34. Image analysis

showed that the Zone 1 sand has similar sphericity and convexity

to fresh NE 34 while diffraction analyses showed quartz contents

(99.6%) just 0.1% lower than for intact NE 34.

10

100

1000

0

20

40

60

80

100

cumulative percentage (%)

particle size (

m)

Fresh sand

Average of Zone 1

Average of Zone 2

Average of Zone 3

Average of Zone 1-2

Fig. 31. Optical grain size distributions defined by Feret mimima for

fresh NE34 sand and Zones 1 to 3: Yang et al 2010

The pile surface was also modified. Multiple Rank Hobson

Talysurf measurements showed that the maximum surface

roughness declined from around 33 to 22μm, while the centre

line average values fell from 3.8 to 2.8μm. The abraded 1μm

thickness of stainless steel would have contributed less than

1/1000

th

of the average thickness (≈ 1mm) of the interface shear

zone, which is compatible with the very slightly (0.1%) lower

quartz content of the Zone 1 material.

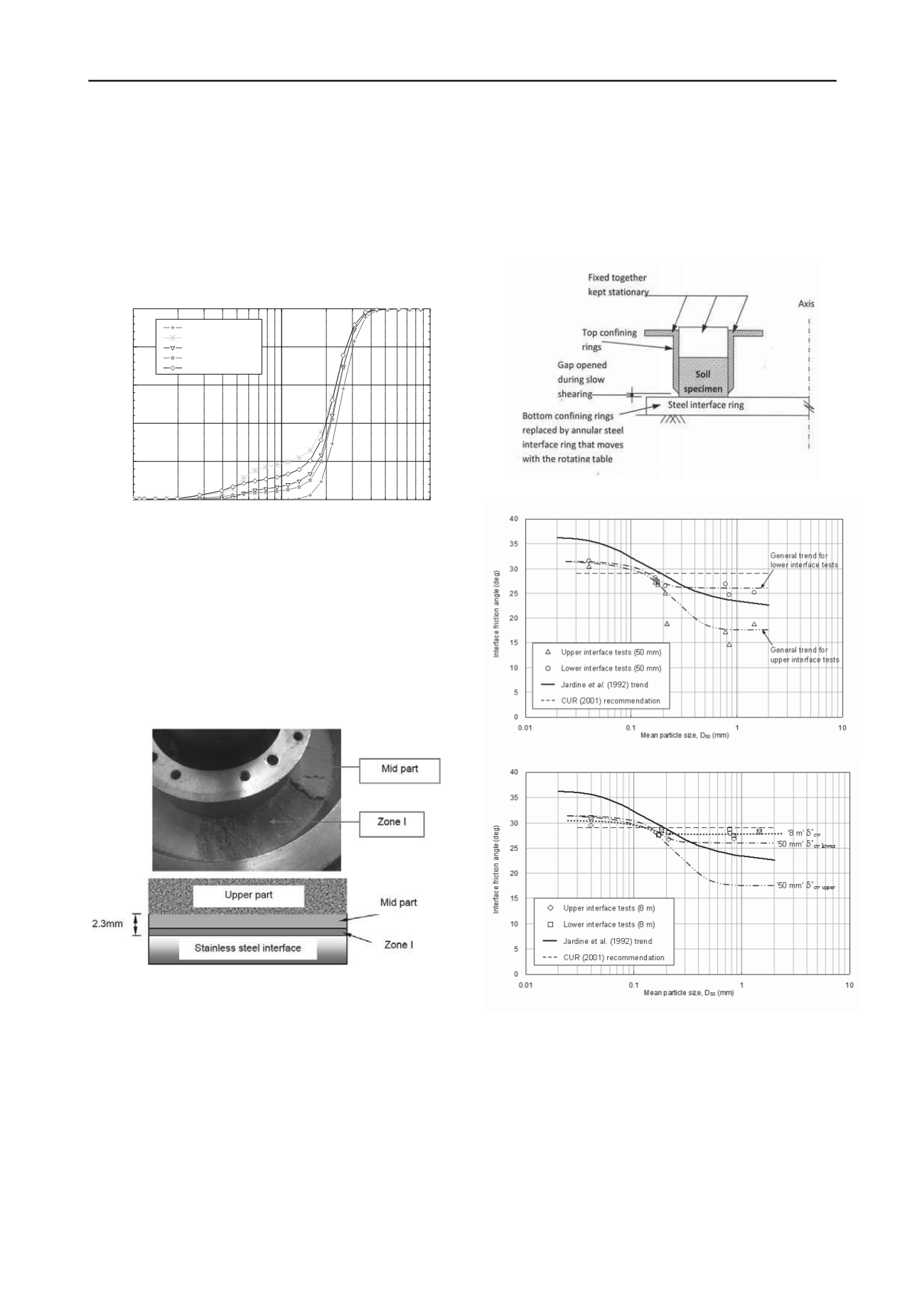

Fig. 32. Photograph and scheme of shear zones from interface ring shear

tests on NE 34 sand; after Yang et al 2010

Parallel interface ring-shear experiments were conducted with

a modified version of the Bishop et al 1971 equipment, shearing

NE 34 against surfaces identical to the pile shaft, at normal

stresses up to 800 kPa. These tests also developed grey ‘Zone 1’

shear bands, as illustrated in Fig. 32, although the bands were

thinner and had lower percentages of broken grains than those

adjacent to the model piles. Ring-shear tests employing the

lower interface configuration shown in Fig. 33 did not reproduce

the high pressure pile tip breakage conditions, but led to closely

comparable δ = tan

-1

(τ

zh

/σ΄

z

) angles to the pile tests that were

practically independent of stress level over 100 < σ΄

z

< 800 kPa.

Ho et al 2011 extended the study, covering a wider range of

gradings with seven silica sands and silts (including NE 34 and

TVS) in ring-shear tests involving interfaces positioned both

above and below the sand samples. Their sweep of δ angles

against d

50

is shown in Fig. 34 where the upper plot (a) shows

trends after shearing to 50mm, while the lower (b) indicates

those after 8m of shear displacement. Also shown are the

‘critical state’ trends suggested by Jardine et al 1992 from low

displacement (5mm) direct-shear interface tests, and by CUR

2001 from cyclic shear box interface tests.

Fig. 33. Lower interface configuration for ring shear tests: Ho et al 2011

Fig. 34. Friction angles from ring shear tests against stainless steel

interfaces with initial CLA roughnesses of 3 to 4μm. Upper (a) results

after 50mm shear displacements, lower (b) after 8m; Ho et al 2011.

It is clear that the angles previously interpreted as stable ‘critical

state’ values in fact vary with test conditions:

The lower interface arrangement led, with d

50

> 0.2mm

sands, to lesser δ angles after 50mm displacements than

equivalent upper interface tests, where fine fragments can

fall from above into void spaces beneath the shear zone.

Lower interface ring-shear tests gave similar trends at 50mm

displacement to (5mm) direct shear interface tests.