48

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

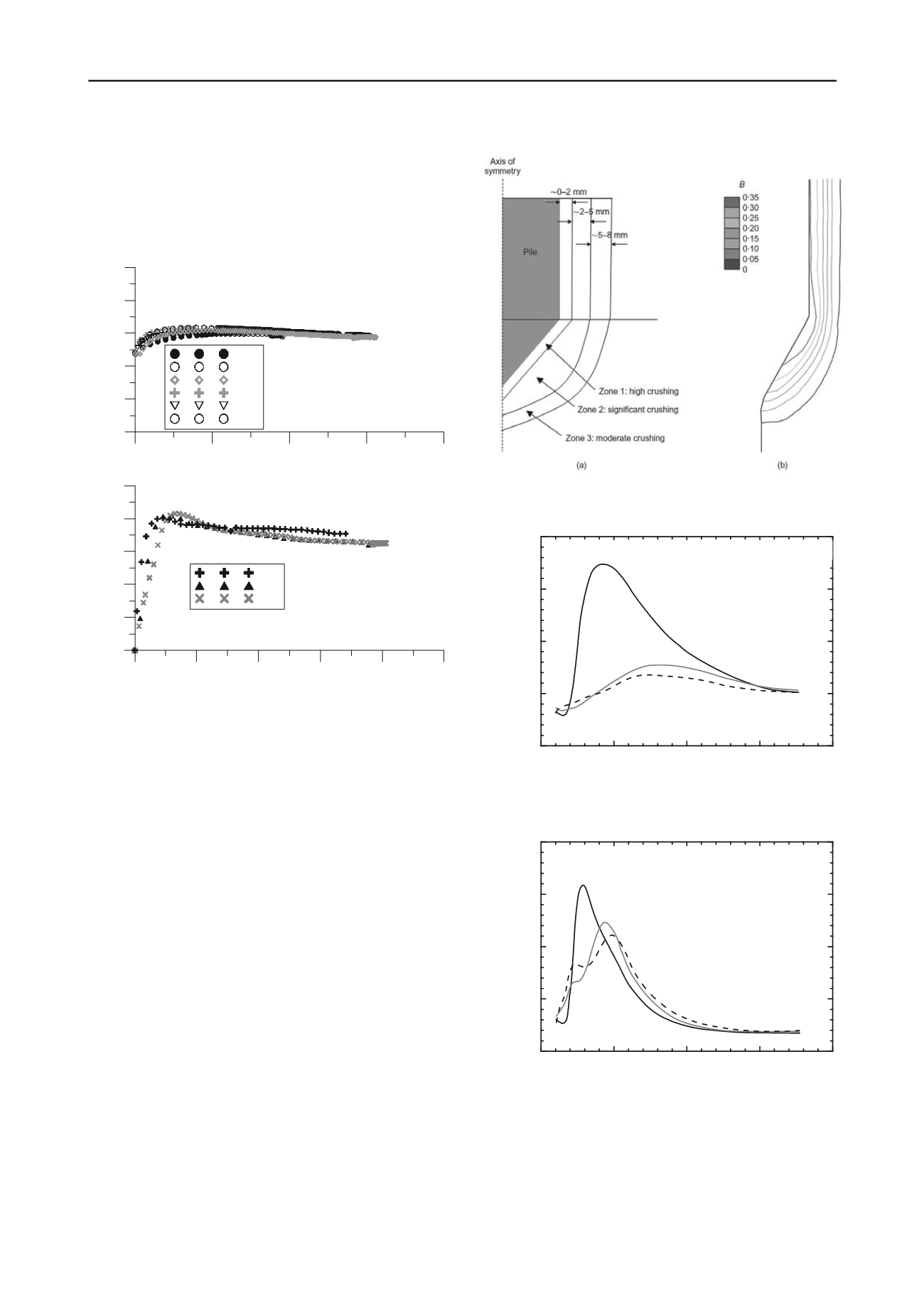

offering relatively low φ΄ beneath and around the tip, to being

dilatant, brittle and able to mobilise far higher peak φ΄ in the

mass that surrounds the shaft. These features were critical to

Jardine et al 2013b’s interpretation of the model pile Calibration

Chamber stress measurements illustrated above in Figures 24 to

27. Further analysis of the evolving family of ‘critical state’ e-p΄

curves developed by crushing is underway by Dr Altuhafi.

0

10

20

30

40

Strain%

0

10

20

30

40

50

', Degrees

P-T1

P-T2

P-T3

P-EE1

P-EE2

P-EE3

Ultimate

'

=30

o

0

5

10

15

20

25

Strain%

0

10

20

30

40

50

'

, Degrees

P-T1

P-T2

P-T3

Ultimate

'= 33

o

Peak

'= 42

o

Fig. 37. Mobilised φ΄ values plotted against axial strain for both high (a)

and low (b) pressure test stages of triaxial tests on NE34 sand: Altuhafi

and Jardine 2011

7 COMPARISON WITH NUMERICAL ANALYSES

Recently published numerical analyses allow further links to be

established between the soil element and model pile

experiments. Zhang et al 2013 present FE analyses of

penetration in sands in which they adopted an Arbitrary

Lagrangian Eulerian (ALE) approach to deal with the implicit

moving boundary problem and a constitutive model that

accounted for grain size distribution evolving through grain

breakage. Their analyses included simulations of the Calibration

Chamber (CC) model pile tests that applied a ‘breakage’

constitutive model that they calibrated against NE 34 laboratory

tests reported by Yang et al 2010 and others.

Zhang et al’s predictions for the Mini-ICPs end-bearing

characteristics were presented in Fig. 24, together with the CC

measurements. The agreement is good when considering the

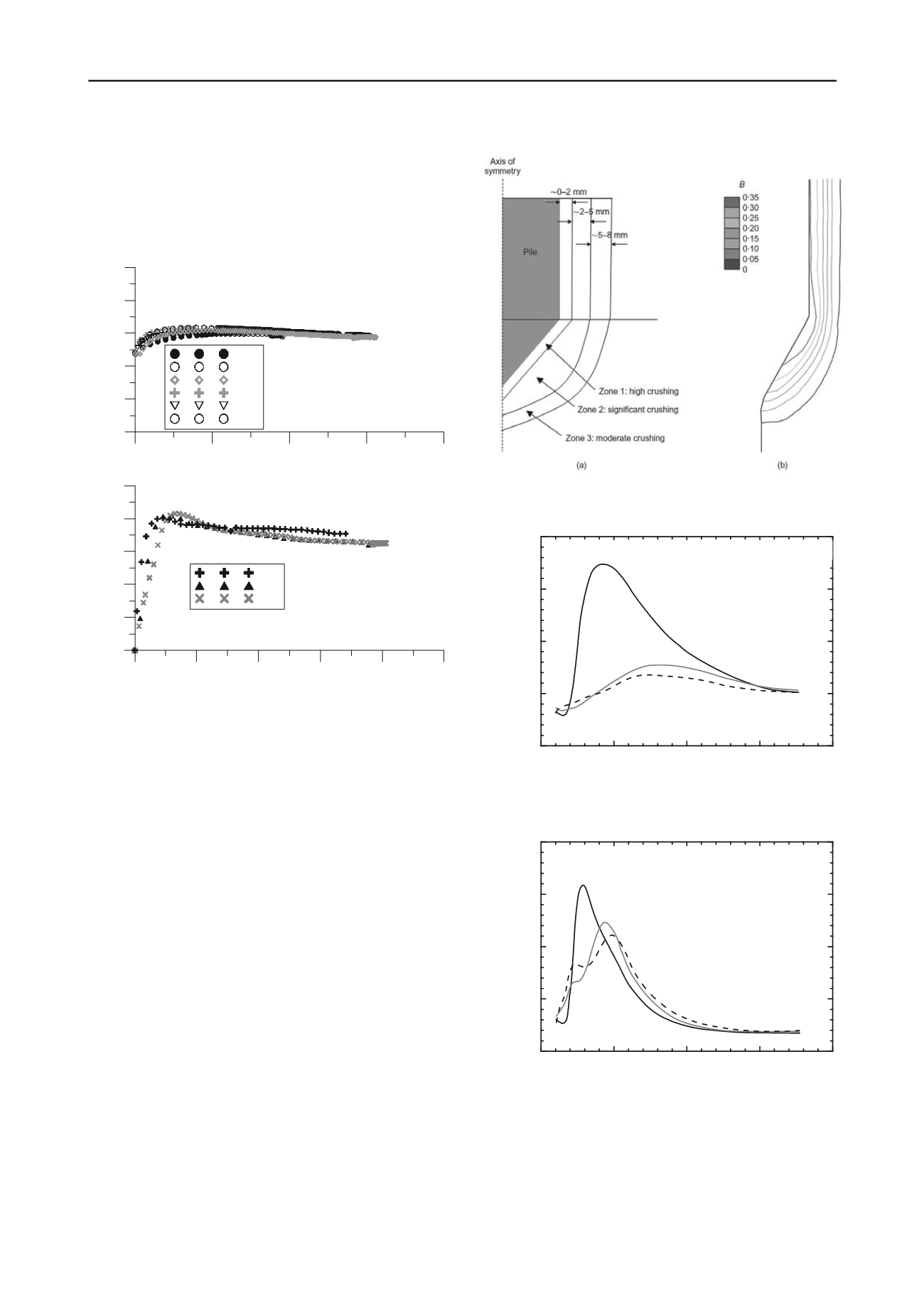

same CC upper boundary conditions. Figure 38 compares the

breakage pattern identified by Yang et al 2010 around the Mini-

ICP pile tip with Zhang et al 2013’s contoured predictions for

their internal breakage parameter B, which scales linearly

between the sand’s initial (B = 0) and ultimate (B = 1.0) ‘fully

crushed’ grading curves. The simulated and experimentally

established patterns are similar, with the maximum B predicted

as ≈ 0.35 close to the shaft, far from the ‘fully broken’ B = 1

limit. The grading curves’ predictions match Yang et al’s

measurements well in all three zones, although they do not

recover the experimentally observed Zone 1 thickness growth

with pile tip depth h/R. The latter is thought to develop through

the un-modelled process of cyclic interface shear abrasion.

Fig. 38. Comparison between (a) Yang et al’s interpretation of breakage

around penetrating Mini-ICP model piles and (b) simulation breakage

parameter B contours for same tests; Zhang et al 2013

0

5

10

15

20

0.0

1.5

3.0

4.5

6.0

h/R=3

h/R=6

'

r

/

q

c

: %

r

/

R

h/R=9

(a) Numerical results by Zhang et al. (2013)

Fontainebleau sand

Fig. 39. Radial profiles of σ΄

r

/q

c

from Zhang et al 2013’s analysis of

Mini-ICP pile in NE 34 sand

0

5

10

15

0.0

1.5

3.0

4.5

6.0

20

(a) Numerical results by Einav (2012)

h/R=3

h/R=6

'

/

q

c

: %

r

/

R

h/R=9

Fontainebleau sand

Fig. 40. Radial profiles of σ΄

θ

/q

c

from Zhang et al 2013’s analysis of

Mini-ICP pile in NE 34 sand.

Correspondence with Zhang, Nguyen and Einav led to

further processing of the stress predictions implicit in their

numerical analyses. Interesting comparisons are presented from

Yang et al 2013 in Figs. 39 and 40, plotting the σ΄

r

and σ΄

θ

predictions transmitted by Professor Einav against r/R. The

stresses are normalised by predicted q

c

, as are the experimental

equivalents shown in Figs. 26 and 27. The overall trends show