45

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

potential to explain the marked field capacity-time trends

illustrated in Fig. 1 by the Dunkerque tension pile loading tests.

6 LABORATORY TESTING AND FABRIC STUDIES TO

INVESTIGATE PARTICLE CRUSHING AND

INTERFACE SHEAR PROCESSES

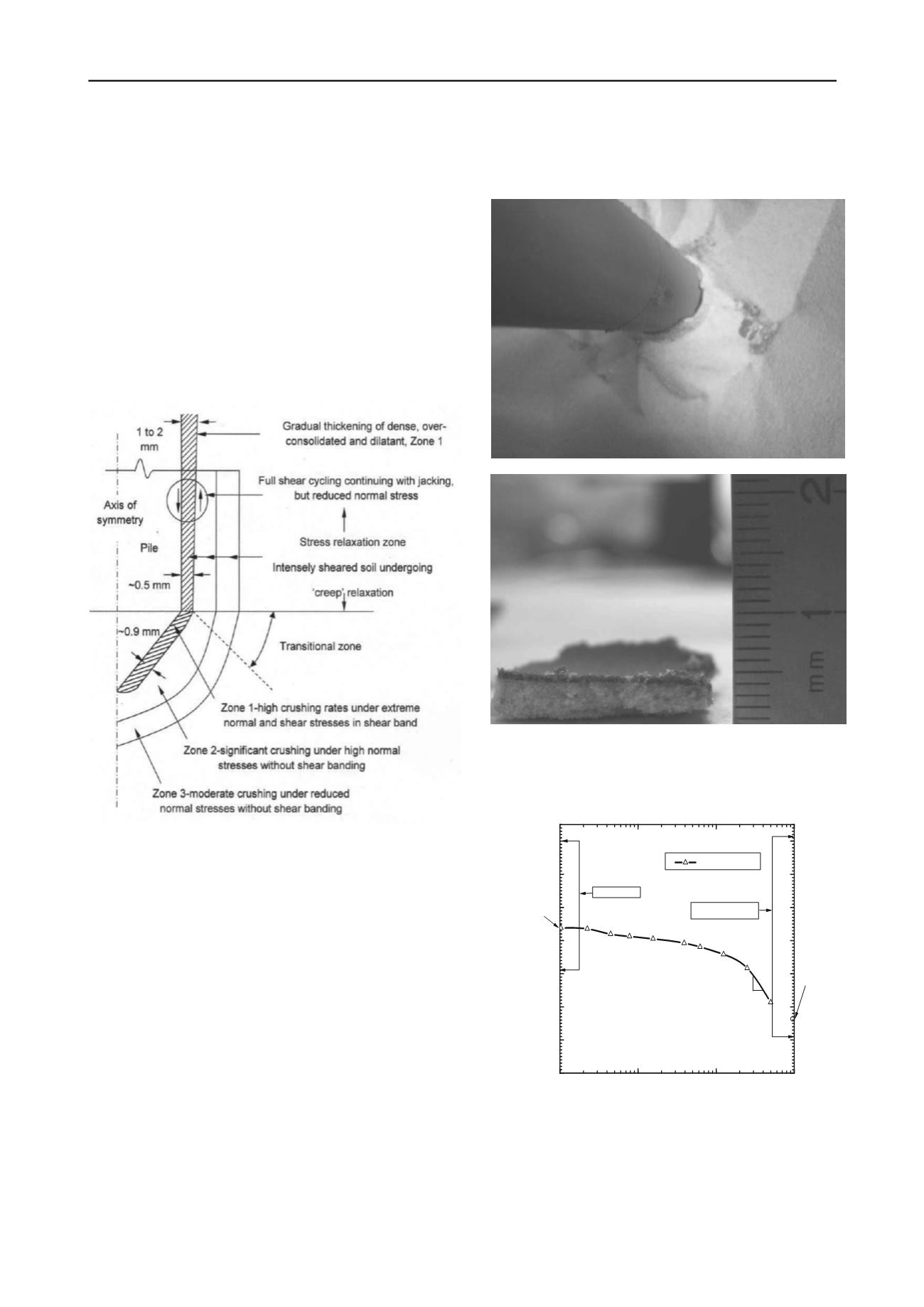

The Calibration Chamber model pile tests also revealed the

important micro-mechanical features illustrated schematically in

Fig. 28. Post-mortem sampling revealed a clearly differentiated

grey coloured interface shear band (Zone 1) around the shaft, as

shown in Fig. 29. The following paragraphs report the insights

provided by laboratory studies into the breakage phenomena.

Their influence on the stress regime developed around the

penetrating pile is considered later.

Fig. 28. Schematic of crushing and interface shearing zones developed

around laboratory model piles: Yang et al 2010

Yang et al 2010 describe how the three concentric micro-

fabric zones were defined, their diameters measured and samples

comprising only a few grams analysed with a QicPic laser-based

imaging system. The latter can resolve particles with sizes

between a few μm and several mm. Care is needed to relate the

various optical definitions of grain size with sieve analyses and

the Feret Minimum optical measurement correlated best. The

grey Zone 1 band contained the highest fraction of modified,

partially crushed sand. Fracture commenced beneath the active

pile tip area once q

c

> 5 MPa. The high pressure oedometer test

on NE 34 sand illustrated in Fig. 30 indicates that large scale

breakage is delayed until σ΄

z

> 10 MPa under K

0

conditions.

Yang et al tested material taken from the Zone 1 shear zone,

finding that breakage reduced the minimum void ratio e

min

very

considerably but had less effect on e

max

. The sand was densified

in the shear zone and manifested a higher relative density in

relation to its modified limits. The original (intact) and modified

(partially crushed) e

min

and e

max

values are shown on Fig 30 for

reference. Although not demonstrated here, the experiments

reported by Altuhafi and Jardine 2011 support the view that a

family of critical state lines evolve as breakage progresses under

high pressure shearing that are also strain-rate dependent. Stable

unique critical states do not appear feasible under such

conditions; Muir-Wood 2008 and Bandini and Coop 2011.

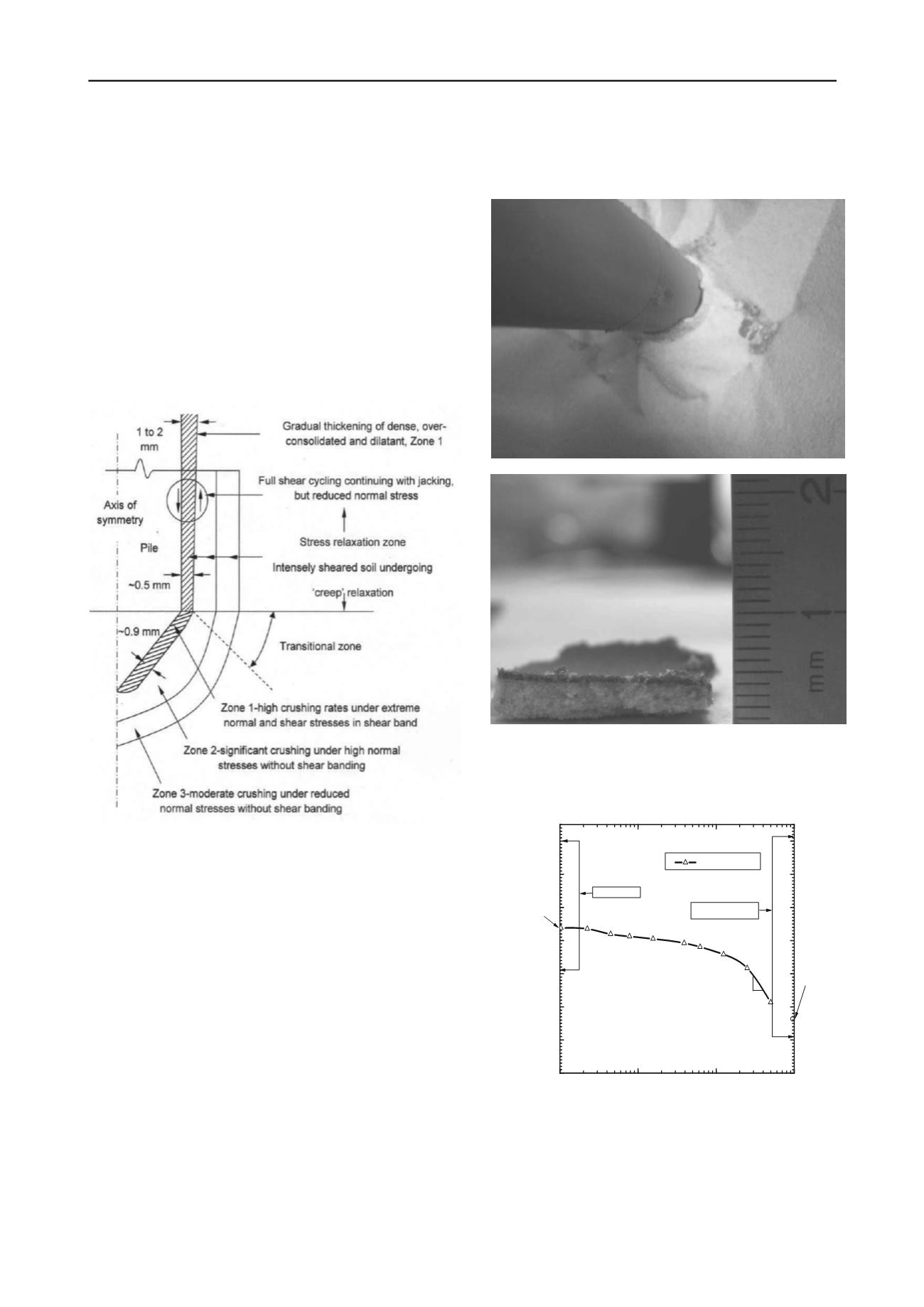

Fig. 29. Photographs of interface shear zone developed around

laboratory model pile: (a) top view from above and (b) side view of

shear zone material: Yang et al 2010

0.1

1

10

100

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Zone1material

e

max

e

min

average Zone 1

unloaded

e

final

=

0.36

e

min

void ratio e

'

v

(MPa)

Loading curve

e

max

Fresh sand

c

c

=0.34

Initial state

e

o

Fig. 30. Void ratio-vertical effective stress relationship from high

pressure oedometer test on NE 34 sand, also showing e

min

and e

max

values

of intact sand (left) and Zone 1 material (right): Yang et al 2010

Once produced, the crushed material is smeared over the

advancing pile shaft giving an initial Zone I thickness ≈ 0.5mm,

which grew to ≈ 1.5mm at any given soil depth as the tip