49

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

0

encouraging quantitative agreement when comparisons are made

between predictions and measurements made at h/R values up to

10; see for example the match between the common curves

given for h/R ≈ 6. Naturally, scope exists to consider further

factors such as: the effects of stress history on dilatancy and

shear strength; creep behaviour; and the extreme cyclic loading

that accompanies pile installation and leads to radial stresses

continuing to reduce with h/R at ratios greater than 10.

8 LABORATORY MODEL PILE TESTS TO

INVESTIGATE CYCLIC LOADING

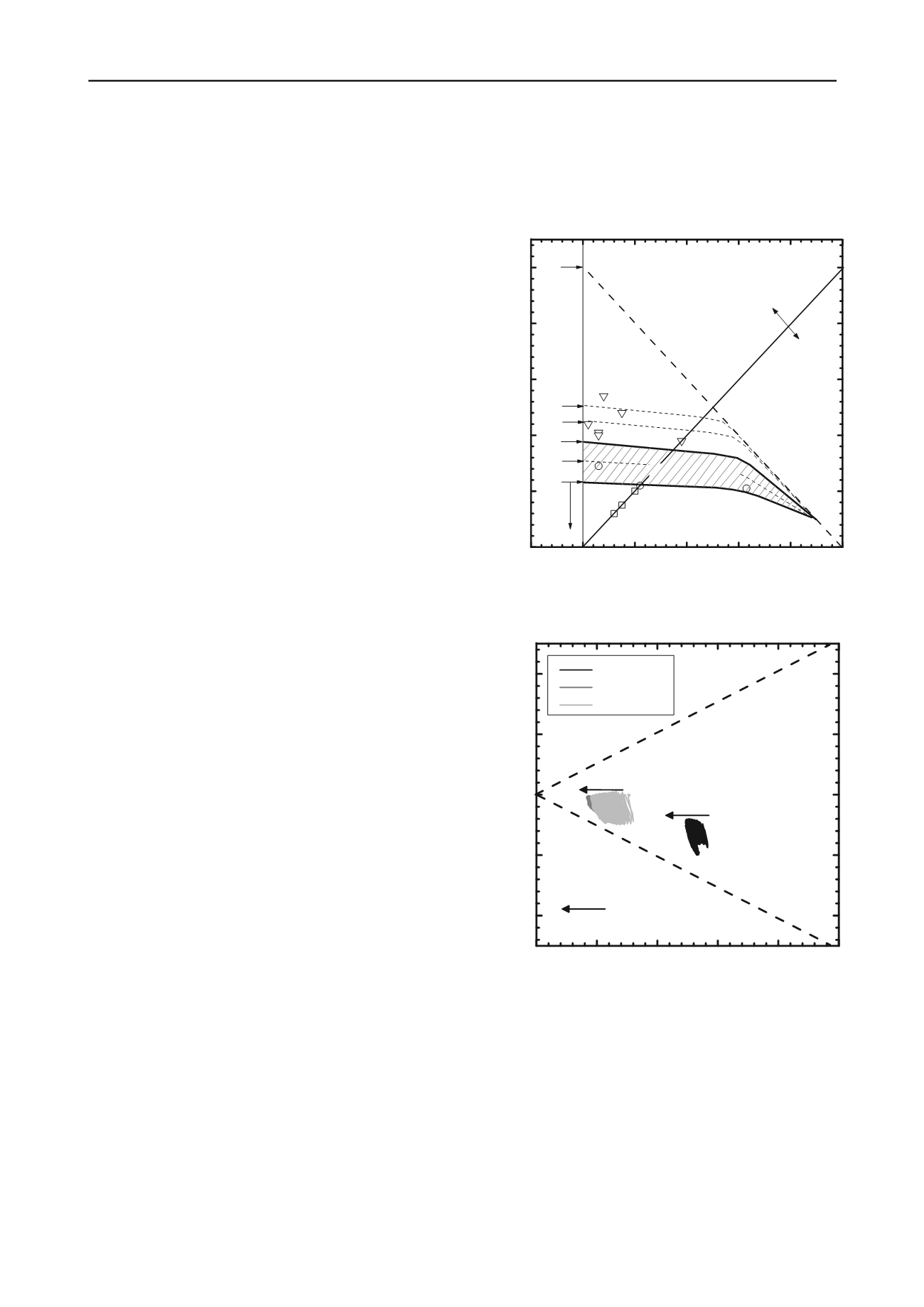

The Mini-ICP Calibration Chamber experiments described in

Section 5 included multiple suites of axial cyclic loading tests

with the model piles installed into pressurised medium-dense NE

34 sand. Cycling was found to have a broadly similar effect on

axial capacity to that seen in the Dunkerque field tests. Figure 41

presents an overall interactive diagram which compares directly

with the field patterns in Fig. 3. Tsuha et al 2012 and Rimoy et al

2013 report on the cyclic stiffness and permanent displacement

trends. Broadly, they classify responses to cycling as:

Stable:

capacity increasing slightly, displacements small

and stabilising) over 1000 or more cycles

Unstable

: reaching failure with 100 cycles, or

Metastable

: falling between these limits

A particular advantage offered by the laboratory model pile

arrangements shown in Figs. 22 and 23 was the ability to

measure the pile-sand effective stress path response directly,

both at the shaft interface (with the Mini-pile’s leading,

Following and Trailing Surface Stress Transducers) and within

the sand mass by the sand-stress senor arrays.

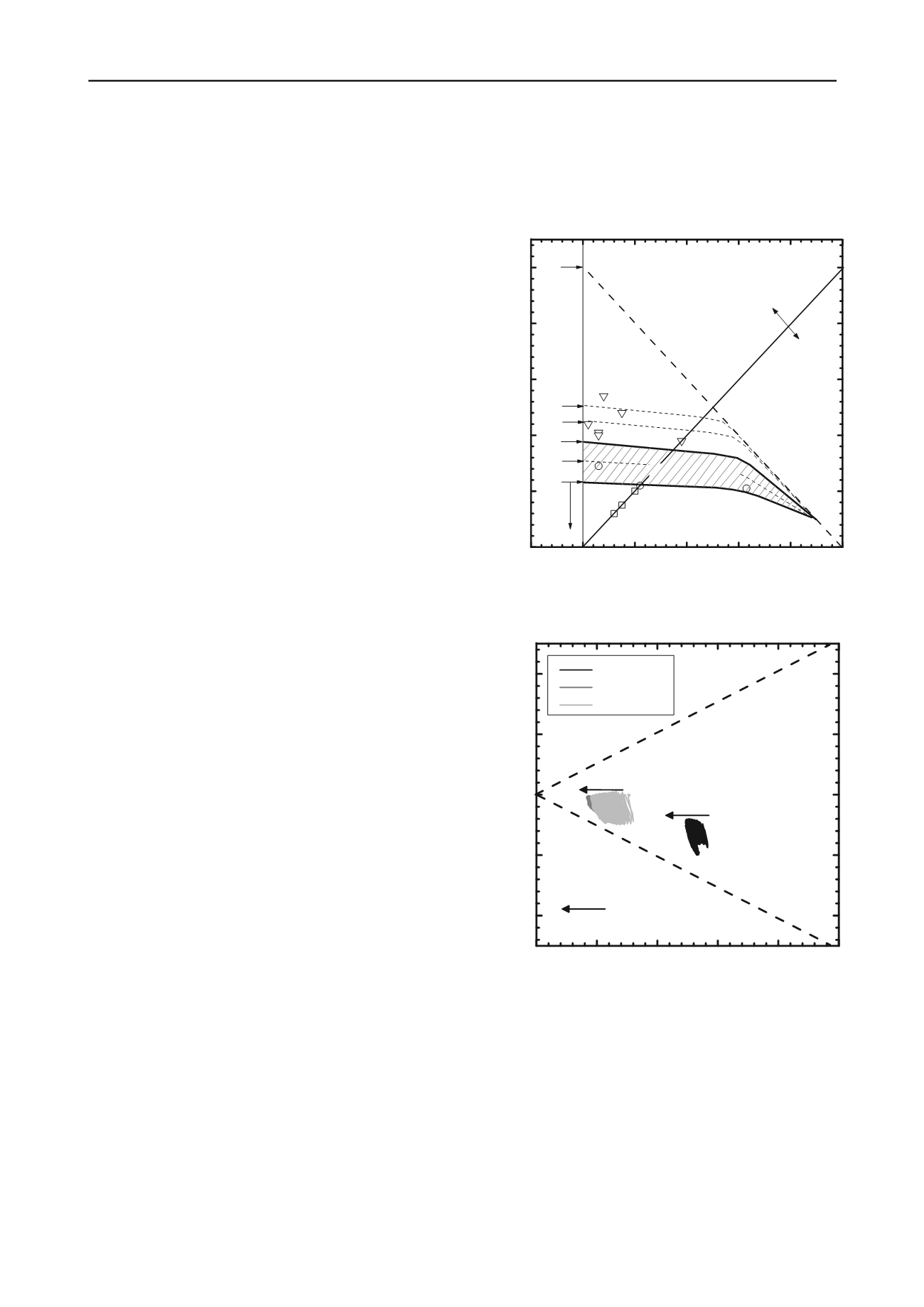

Figure 42 illustrates the local interface effective stress paths

followed under Stable conditions in a 1000 cycle experiment.

The patterns resemble those seen in Constant Normal Stiffness

(CNS) shear experiments (see for example Boulon & Foray 1986

or Dejong et al 2003) with radial effective stresses increasing

under tension loading (that generates negative shaft shear stress)

and decreasing under compressive load increments around the

relatively rigid Mini-ICPs. While the load-displacement response

is in-elastic (non-linear and hysteretic) under even low-level

cycling, the radial effective stress changes and pile head

movements induced by each cycle are small.

The effective stress paths appear to match, approximately,

the Y

2

criteria described in Section 2 and traced by Kuwano and

Jardine 2007 in small strain triaxial probing tests. Rather than

remain exactly static, the radial stresses reduced, albeit at very

slow rates, over time indicating a tendency towards contraction

and migration towards the interface shear failure criterion angles

established by Yang et al 2010 through interface ring shear tests,

or those shown in Fig. 34 from Ho et al 2011. The continuing

rates of radial stress reduction might also be related to very slow

rates of continuing interface surface abrasion and particle

modification.

Multiple static tension tests on the Mini-ICPs showed shaft

capacities increasing (by up to 20%) as a result of stable cycling,

mainly due to changes in loading stress-path geometry that gave

a less contractive response under static loading. The Dunkerque

field tests also showed tension capacity increasing after a stable

1000 cycle test; Jardine and Standing 2013. Figures 43 and 44

demonstrate the contrasting responses seen in Metastable tests

under One-Way (OW) and Two-Way (TW) loading respectively.

All paths approach the interface failure envelope as cycling

continues, either asymmetrically under OW loading or more

symmetrically in the TW test. The milder OW test shows a

similar pattern to the Stable test shown in Fig. 40, except that it

migrates more rapidly and engages the critical δ= 27

o

failure

line, leading to the onset of local slip after several hundred load

controlled cycles. The more severe TW test progressed further

and developed a full failure system with a ‘butterfly-wing’

effective stress path pattern resulting from slip displacements

that generated dilatant loading stages followed by sharply

contractant unloading stages.

-0.2 0.0

0.2

0.4

0.6

0.8

1.

0.0

0.2

0.4

0.6

0.8

1.0

N

f

= number of cycles to failure

One way

Q

cyclic

/Q

T

Q

mean

/Q

T

Two way

Stable

Meta-Stable

Unstable

>1000

N

f

=

1

10

100

1

4

10

66

170

4

500

1000

500

5

Fig. 41. Effects on shaft capacity of cyclic loading. Interactive

stability diagram from Mini-ICP CC tests: Tsuha et al 2012.

0

100 200 300 400 500

-200

-100

0

100

200

'

=27

o

Shear stress

rz

(kPa)

Radial stress

'

r

(kPa)

Leading A

Following B

Trailing C

Direction of

radial stresses

Fig. 42. Interface shear τ

rz

- σ΄

r

effective stress paths: Stable

cyclic test ICP4-OW1: Tsuha et al 2012.

Close examination reveals the top-down progressive failure

process described by Jardine 1991, 1994. The points where

behaviour switches from contractant to dilatant fall on an

interface Phase Transformation line analogous to that noted by

Ishihara et al 1975.