358

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

method for frost susceptibility of soils, which uses specimens in

a disk form 10 cm in diameter and 5 cm in thickness and is

capable of falling head permeability tests using a burette before

and after a freeze-thaw cycle (designated hereinafter as the frost

heave test apparatus capable of permeability tests). The second

is a frost heave test apparatus equipped with bender elements

(BEs) for measuring the velocity of shear waves propagating in

the specimen before and after a freeze-thaw cycle (designated

hereinafter as the frost heave test apparatus equipped with BEs).

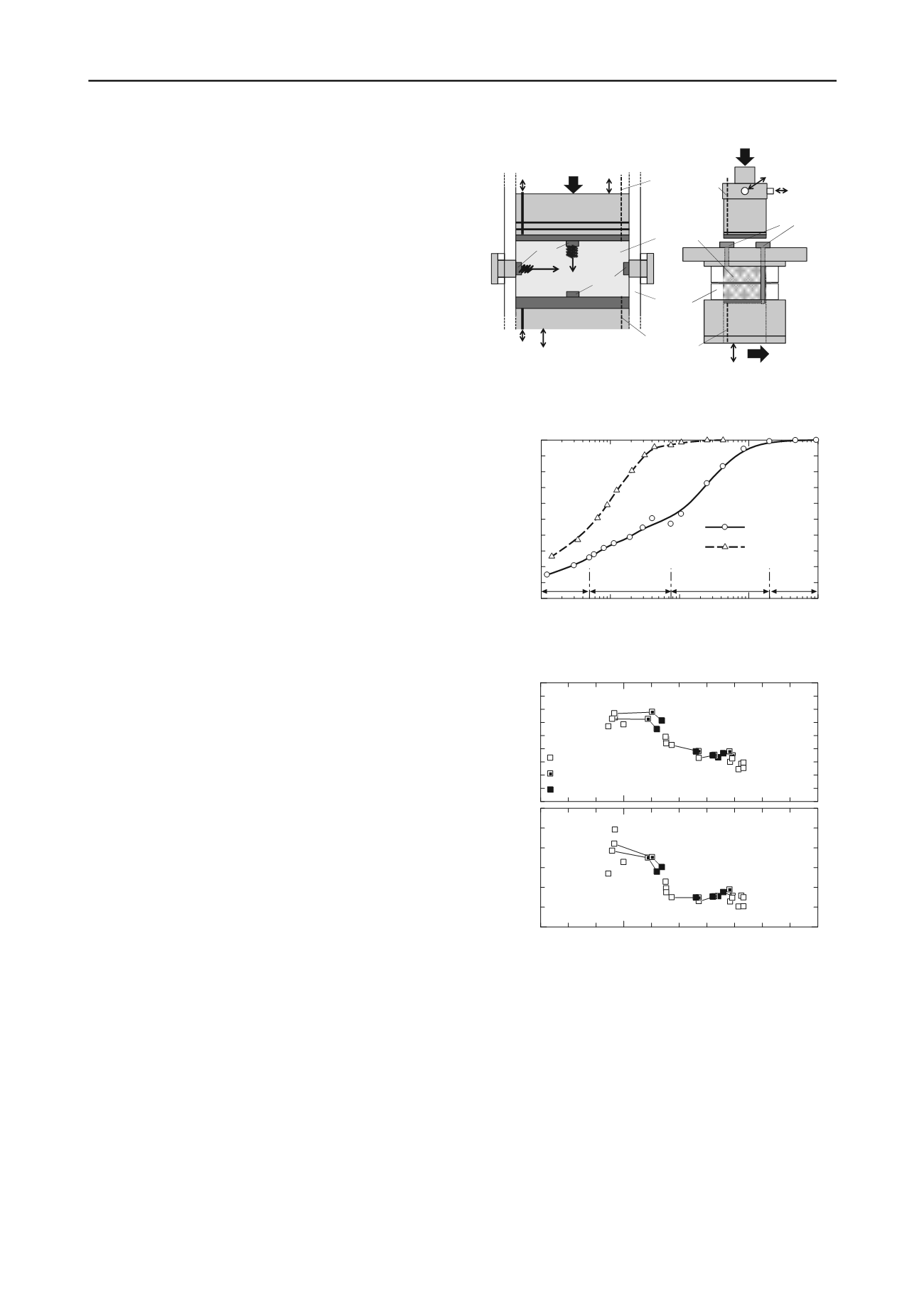

As shown schematically in Figure 2a, two pairs of BEs are

provided, in the upper and lower plates and in the mold,

respectively. The BE pair in the cooling plates measures the

velocity (

V

s

)

vh

of the shear wave that oscillates horizontally and

propagates vertically, while the BE pair in the mold measures

the velocity (

V

s

)

hh

of the share wave that oscillates and

propagates horizontally (Kawaguchi et al. 2001, Yamashita and

Suzuki 2001). The BE pair in the mold was removed in freeze-

thaw tests to avoid any damage by freezing, and mounted again

after thawing for BE tests. The third apparatus is a direct box

shear test apparatus that permits freeze-thaw test in the shear

box (designated hereinafter as the temperature-controllable

direct box shear apparatus). The shear box is schematically

represented in Figure 2b. The specimen is a disk 6 cm in

diameter and 4 cm in thickness. A coolant is circulated in the

piston and pedestal for temperature control. The shear box, or

the circumferential surface of the specimen, is thermally

insulated by a two-centimeter-thick acrylic resin layer. A rubber

sheet, 0.3 mm in thickness, is placed between the upper and

lower halves of the shear box during freeze-thaw tests to

prevent water leakage, and is removed for shear tests to leave a

0.2mm clearance between the box halves.

Figure 3 shows grain size distribution curves for the two

frost-susceptible fine-grain soils used in this study. One is

weathered volcanic ash obtained at Kitami City, Hokkaido

(sample V) which was used in the tests using the two frost

heave test apparatus. The test specimens were prepared by

compacting the volcanic ash sample conditioned to be slightly

drier than with the optimum water content. The other, used in

the temperature-controllable direct box shear tester, is a mixture

of clay commercially available in dry powder and silt at a ratio

of 1:1 by weight, which was made to a slurry at twice the liquid

limit and then consolidated one-dimensionally to a vertical

stress

v

= 100 kPa (sample CL,

w

L

= 38%,

I

P

= 19).

3 RESULTS AND DISCUSSION

3.1

Void ratio and coefficient of permeability

Falling head permeability tests were performed before and after

the freeze-thaw tests using the frost heave test apparatus in

order to study effects of freeze-thaw cycles on the void ratio

e

and the coefficient of permeability

k

. Sixteen specimens were

prepared using a rammer and a mold at three levels of

compaction energy: 126, 284, and 550 kJ/m

3

(Nakamura et al.

2011). The vertical stress was

v

=10 kPa for all the tests. Six of

the specimens underwent three freeze-thaw cycles and

k

was

measured before and after each cycle. The frost heave test

method specified in the JGS 0172-2009 standard was used. In

the thawing tests, the specimen was dewatered through the top

and bottom surfaces held at 5

C, and then saturated again.

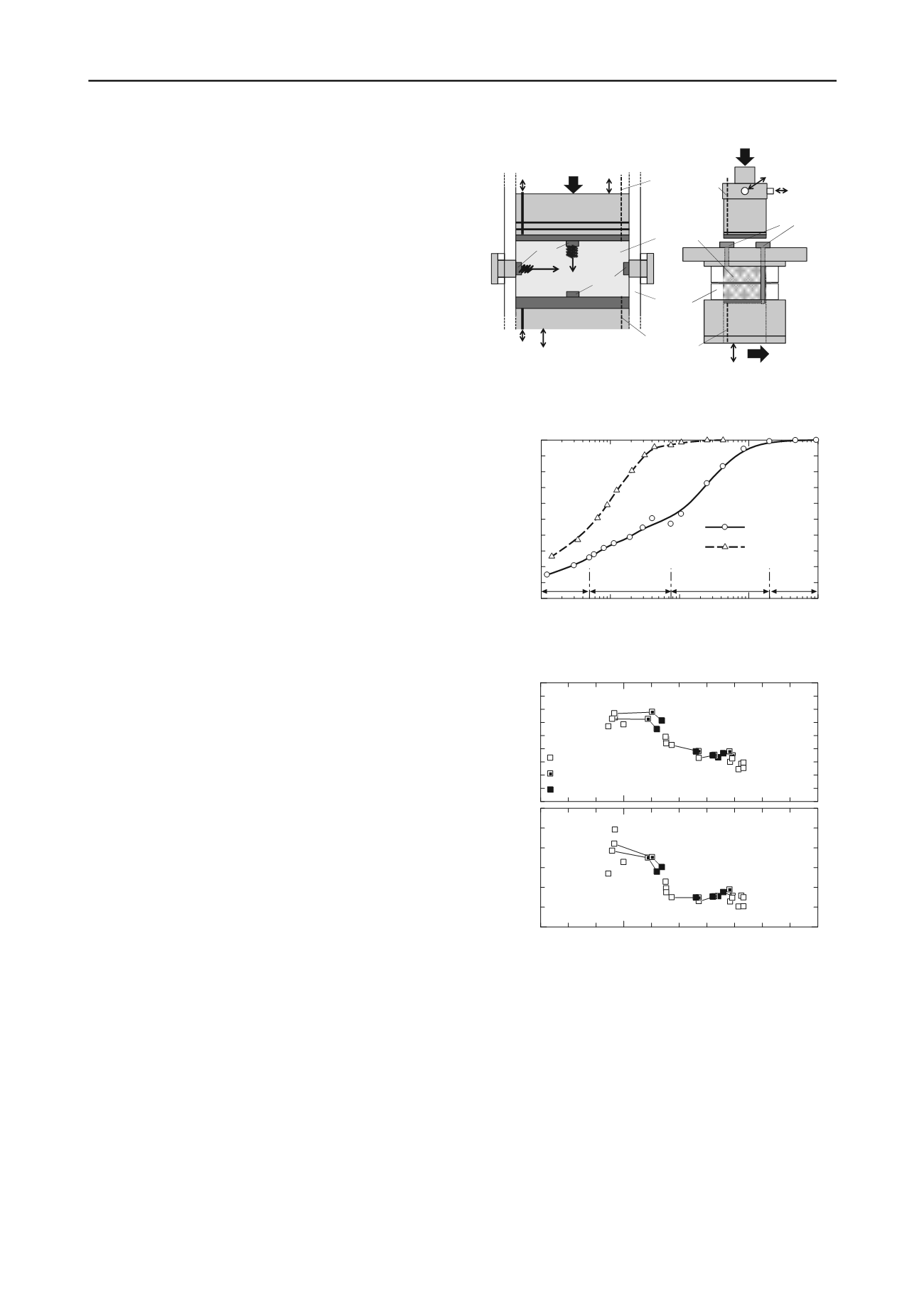

Figure 4 shows the rate of frost heave

U

h

(mm/h) and frost

heave ratio

ξ

(%) of the specimen as functions of void ratio

e

at

the beginning of freezing. A greater

e

means more pore water

and lower tensile strength, which might suggest easier ice lens

formation. Actually, however, both

U

h

and

ξ

are lower at higher

e

at the beginning of freezing, presumably because of inhibition

of continuity of the unfreezable water needed for frost heave

(Nakamura et al. 2011). The results of the three consecutive

freeze-thaw cycles, indicated by the points connected with lines,

show that the repeated cycles lead to convergence to fairly

constant values of

U

h

and

ξ

.

Figure 5 represents changes in the void ratio

e

and

coefficient of permeability

k

of the specimen through the freeze-

thaw cycles. The data for each specimen are connected by lines.

As observed in Figure 4, the freeze-thaw cycles decrease greater

initial

e

values and increase smaller initial

e

values, eventually

leading to convergence to a relatively limited range of

e

values

between 1.1 and 1.3. Ono et al.(2003) reported that freeze-thaw

history decreases

e

of clay at a normally consolidated state and

increases

e

of clay with a larger over consolidation ratio. This

observation is in agreement with the present results assuming

that higher compaction energies on the specimen result in over

consolidation in terms of the specimen’s mechanical

0.001

0.01

0.1

1

10

0

20

40

60

80

100

Percent passing (%)

Grain size

Clay

Silt

Sand

Gravel

: Sample V

: Sample CL

Screw

Resistance

temperature

detector

Acrylic

resin

Coolant

Specimen

(mm)

Figure 2. Test apparatus diagrams (a): frost heave apparatus equipped

with BEs, b): temperature-controllable direct box shear apparatus)

Figure 3. Grain size distribution of samples used in the tests

Figure 4.

U

h

and

ξ

as functions of

e

at the beginning of freezing

Water

Vertical stress

Water

BE

(

V

s

)

vh

(

V

s

)

hh

BE

Upper plate

Lower plate

Piston

Shear

Vertical stress

Coolant

Coolant

Coolant

Water

Resistance

temperature

detector

a)

b)

0.2

0.4

0.6

0.8

1.0

Rate of frost heave

: Cycle 1

: Cycle 2

: Cycle 3

Sample V

U

h

(mm/h)

0.8

1.0

1.2

1.4

1.6

0

40

80

120

Frost heave ratio

Void ratio at the beginning of freezing,

e

(%)