354

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

=

1

−

3

1

−

3

≤ 1.0

(3)

Where (

σ

1

-

σ

3

)

f

= the deviatoric stress at failure.

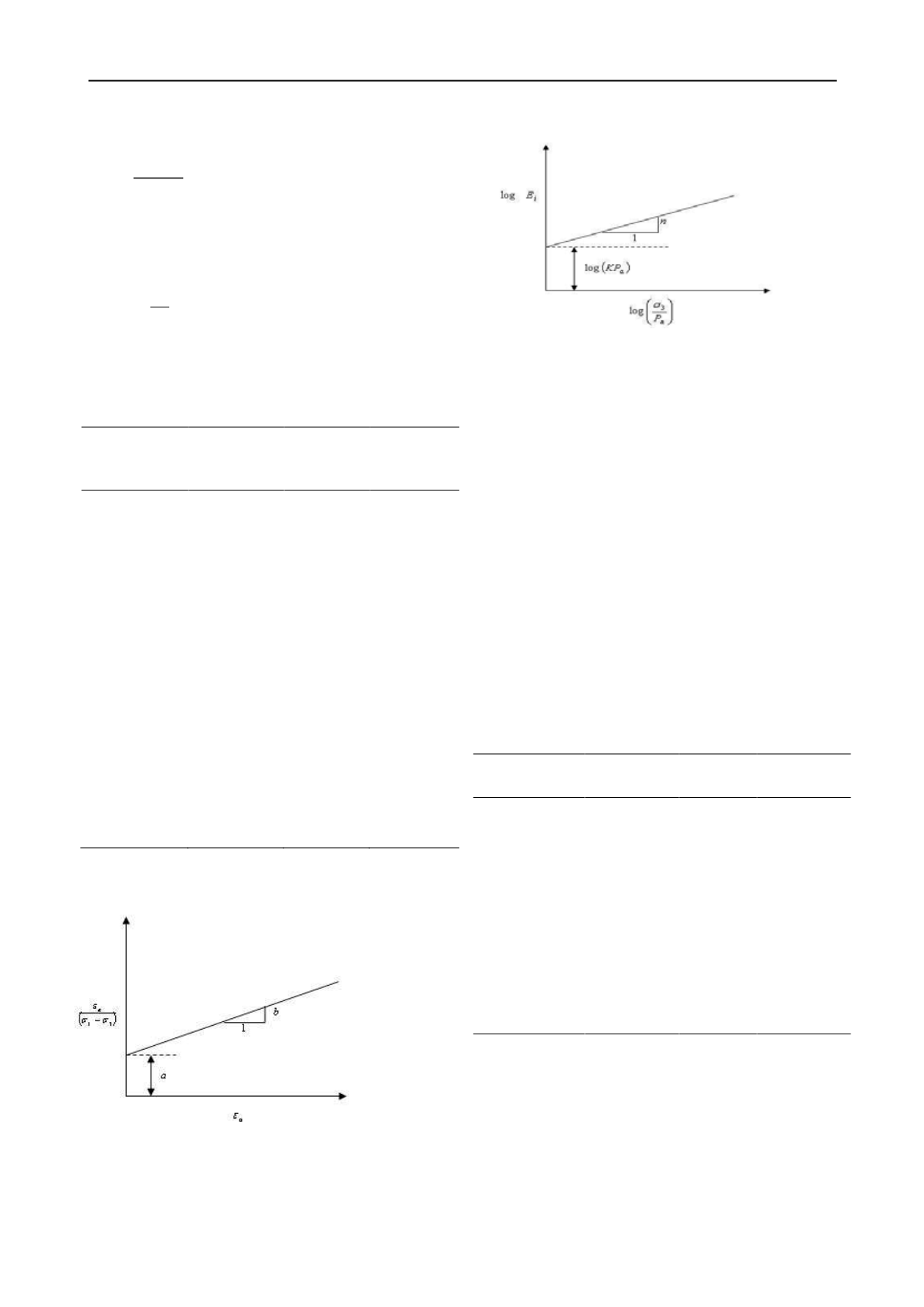

The following relationship for the initial modulus of

elasticity for soils is suggested (Janbu 1963):

n

a

a

i

P

kP E

=

3

σ

(4)

Where, n represents the exponential effect of

σ

3

on E

i

. K and n

can be determined by drawing a line fitted to data of the triaxial

tests, as presented in Figure 2.

Table 1. Mechanical properties of three rockfill materials

Rockfill Type

Australia

Railway

Ballast

Roodbar

Dam

Material

Yamchi

Dam

Material

Mineralogy

Latite

basalt

Lime

stone

Andesite

D

min

(mm)

20

0.15

0.072

D

max

(mm)

65

50.8

74.3

C

u

1.5

23

65.4

σ

3

(kPa)

90

120

240

500

700

900

200

400

700

φ

°

54.6

52

45.8

30.6

38.7

B

g

*

(%)

10

11

12

13.5

NIA

**

Shape

Highly Angular

Angular/ sub

Angular

Rounded

* *

NIA: No Information Available

*

B

g

: Marsal’s breakage index

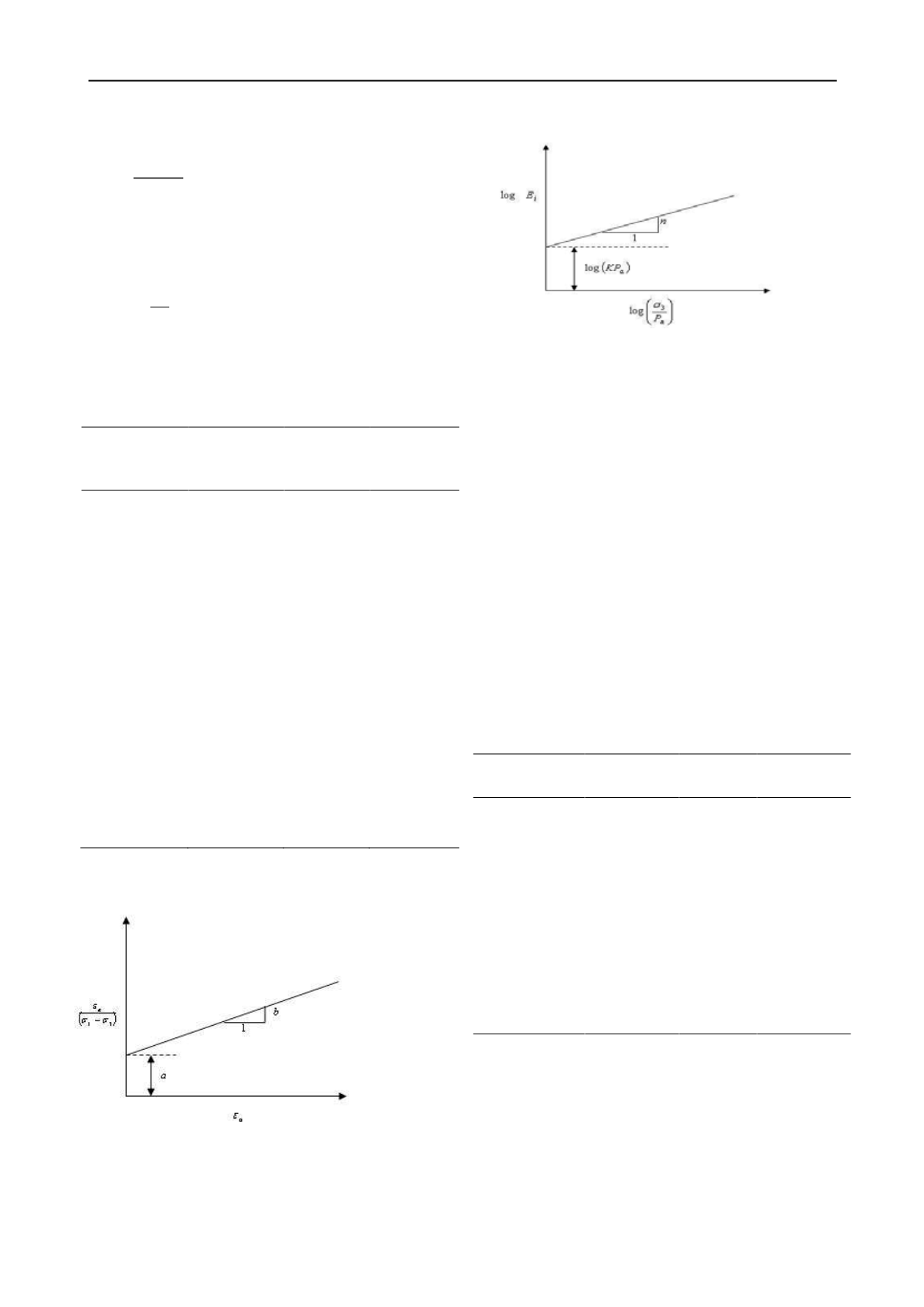

Figure 1. Determining constants a and b from a triaxial test results

Figure 2. Determining constants n and K from three triaxial tests results

3.2.

Application of the model

In this section, the mechanical behavior of the thirty rockfill

materials, which the characteristics of three types of them are

presented in Table 1, are investigated analytically in the

framework of the Hyperbolic Model. Values of parameters n

and K for the materials introduced in Table 1, for every two

consecutive triaxial tests, and furthermore, for three triaxial

tests, are extracted and presented in Table 2. Therefore, for each

of the materials three values of n are calculated; one from the

first and second triaxial tests results, one from the second and

third triaxial tests results, and one from first, second and third

triaxial tests. We intentionally calculated the first two values for

n to highlight the effect of particle breakage on E

i

(through n)

with every increase of

σ

3

. This is different from the similar

procedure of determining n for soils, where usually a unique n

value can be extracted from results of triaxial tests with three

consecutive confining stresses (

σ

3

) on a given material. The

details of determining n and K from the triaxial tests results are

given in Duncan and Chang 1970.

Table 2. Values of n and K parameters for the rockfill materials

introduced in Table 1

Rockfill Type

(

σ

3

)

1

, (

σ

3

)

2

(kPa)

n

K

Australia

Railway Ballast

90, 120

-7.45

3500

120, 240

-0.95

1070

90,120 ,240

-3.32

2100

Roodbar Dam

Material

500, 700

-6.53

18×10

8

700, 900

-1.15

52000

500,700, 900

-3.26

10×10

5

Yamchi Dam

Material

200, 400

2.7

1180

400 , 700

0

5×10

4

200,400, 700

1.5

3000

Table 3 compares the average values of n for the relatively

rounded and relatively angular rockfill materials of this study

separately, with typical values for loose and dense sands. As

expected, the average n for the rockfill materials are far less

than that of the typical dense sand; moreover, n reduces with

increasing of the materials' angularity. It should be mentioned

that highly angular, angular, angular/sub angular and sub

angular materials are assumed as relatively angular materials;

while, rounded, rounded/sub rounded and sub rounded ones are

assumed as relatively rounded materials.