352

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

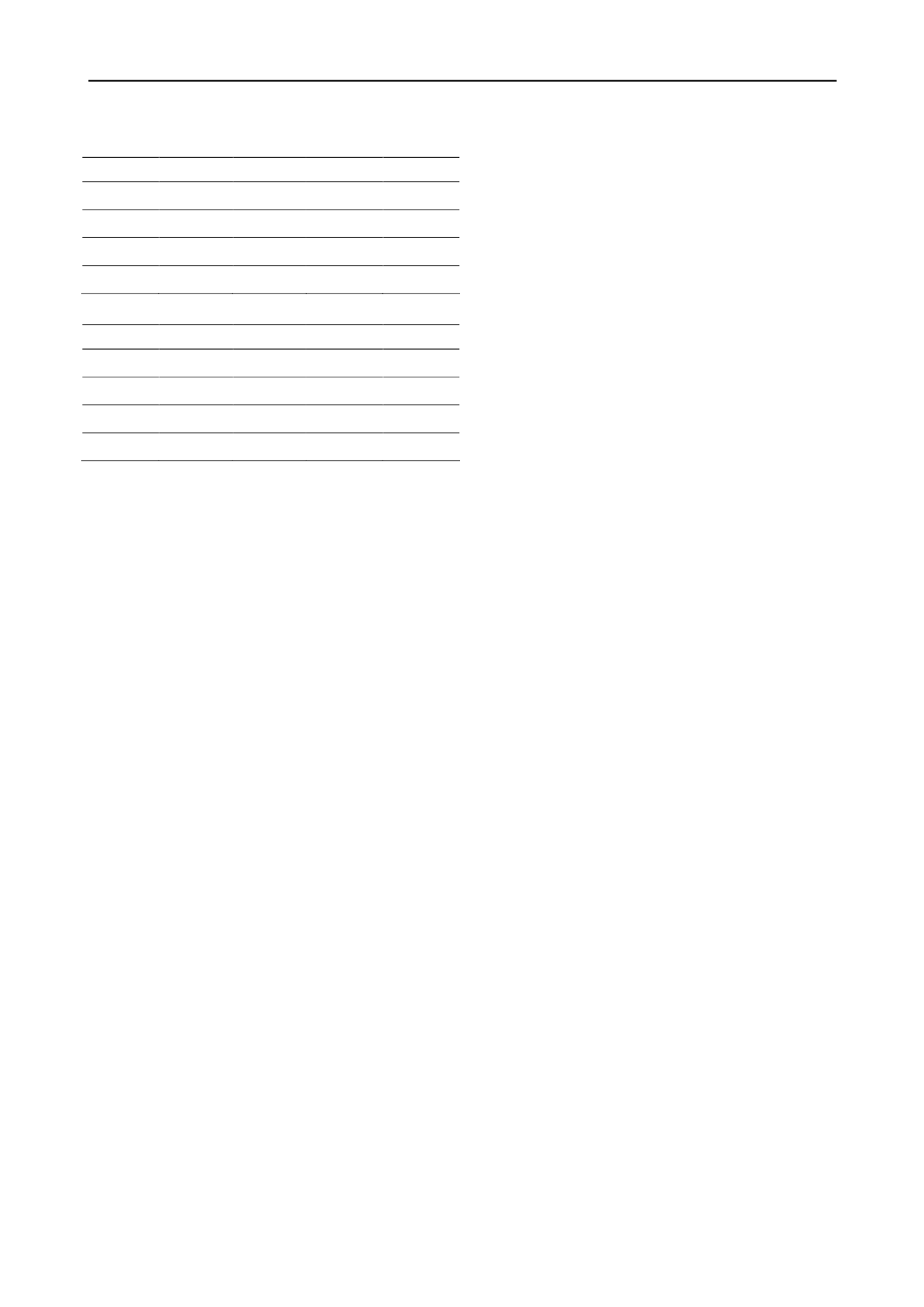

Table 6. Results of the statistical tests -

s

max

I

II

III

IV

I

+

-

+

+

II

-

+

+

+

III

+

+

+

IV

+

+

+

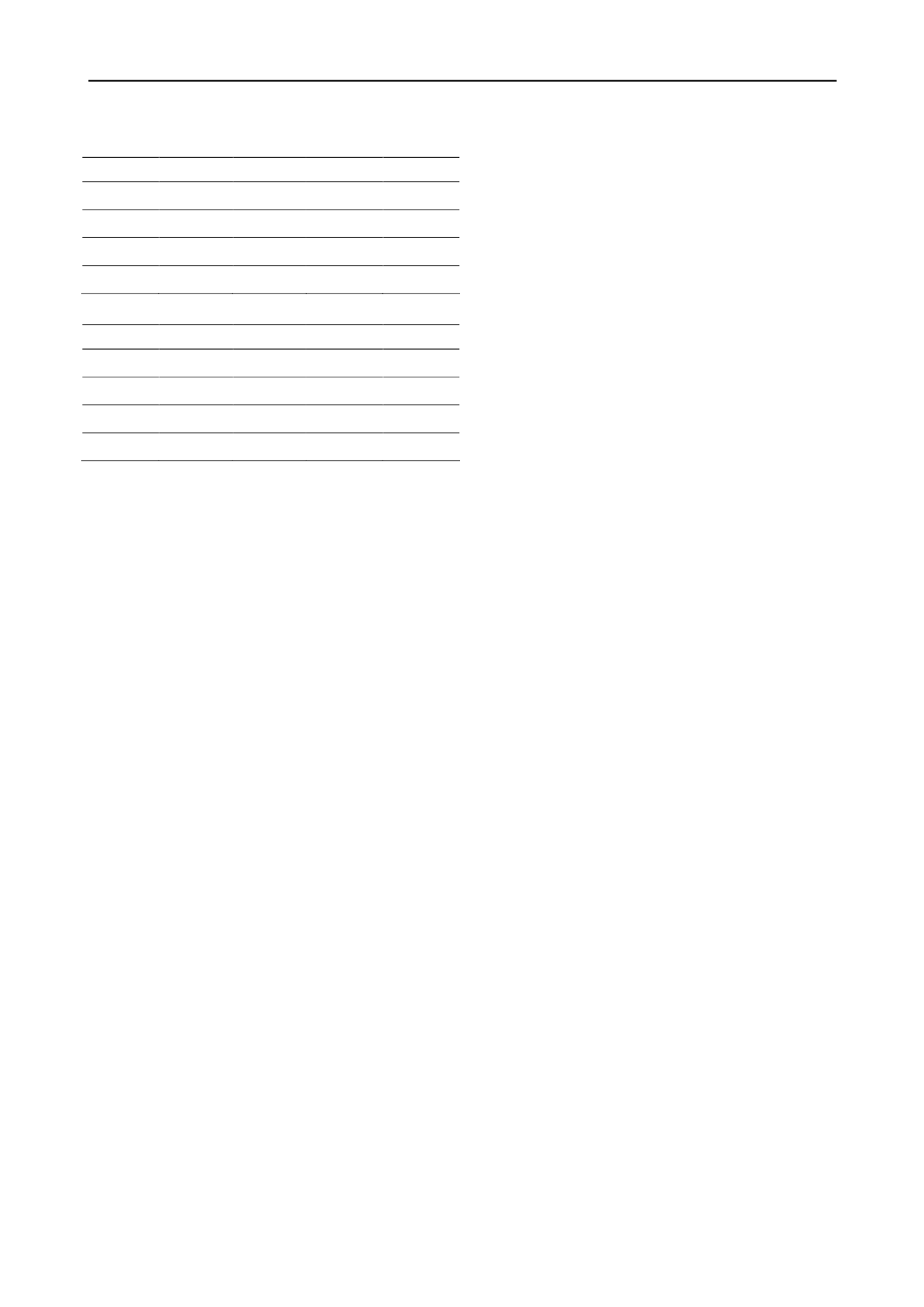

Table 7. Results of the statistical tests

–

ratio

s

min

/

s

max

I

II

III

IV

I

+

-

-

-

II

-

+

+

+

III

-

+

+

IV

-

+

+

4 DISCUSSION, CONCLUSIONS

4.1

The statistical features of the data bases

The ratio of the minimum and the maximum dry density is

statistically constant for sands since the coefficient of the

variation is very small. The coefficient of variation of the

e

ratio is equal to 0.061 for the calibration chamber sands; 0.060,

0.082 and 0,125 for the Groups sands I and III to IV,

respectively. The coefficient of variation of the

s

ratio is equal

to 0.024 for the calibration chamber sands; 0.0116, 0.025 and

0,044 for the Groups sands I and III to IV, respectively.

This result implies linear correlations between the minimum

and the maximum dry density data. The Pearson coefficient of

correlation at the

s

min

–

s

max

and

e

min

- e

max

was equal to 0.99,

0,99 for the Danube sands I indicating that both the

s

min

–

s

max

and

e

min

- e

max

relations are linear. The Pearson coefficient of

correlation at the

s

min

–

s

max

and

e

min

- e

max

was equal to 0.84,

0.85; 0.89 and 0.88 and; 0,64, 0,65; respectively for Groups II,

III and IV

–

being smaller, still indicating linear correlation.

The smallest coefficient of variation values (and, the largest

correlation values) of Group I sand data (produced by using the

Proctor mold for maximum void ratio) can be attributed to the

facts that the quality of testing on was good and the tested soils

were homogeneous (having continuous distribution only).

4.2

The information concerning the dry density ratio

The results of the statistical tests indicate that the ratio

s

min

/

s

max

is about equal about to 0.76 for Group I where the Proctor mold

is used for the minimum dry density test and the ratio

s

min

/

s

max

is about equal about to 0.62 for the remainder Groups where a

different mold is used (i.e. the two newly tests sand databases

–

being tested with the German Standard

–

and the Calibration

Chamber sands).

The result of the statistical tests (Tables 5 to 7)

–

show that

the minimum dry density data are significantly different for

Group I and the remainder groups but the maximum dry density

results are similar.

The significant difference in the minimum dry density

testing methods can be attributed to the fact that the molds have

different sizes (Fig 1). This point needs some further (e.g.

micromechanical) research.

4.3

The dependence of the dry denisty on the diameter

In accordance to the expectations, the measured

s

min

and

s

max

values slightly increase with the maximum grain diameter

d

max

in the tested sand databases (Figs 5 to 6).

However, an increasing bias with grain diameter - possibly

due to arching

–

is found in the minimum density results. As it

can be seen on Figure 2, the density increase is not possible to

be reproduced by the DIN 18126 for fractions being larger than

0,5 mm, instead of this, even a decrease is experienced.

4.4

Conclusions

The different dimension of the mold of the various minimum

dry density tests has some impact on the test results as follows.

The smaller width and same height may cause some kind of

arching which leads to smaller minimum dry density values and,

this effect is the function of the grain diameter.

As a by-product of the research, an additional comment can

be made. The result of the statistical analysis indicates that the

equivalence of the Modified Proctor procedure and the

Vibrating Table procedure (Poulos and Hed, 1974) can be

extended to the DIN maximum dry density testing method.

Some further research is suggested, including the separation

of the continuous and gap-graded mixtures and, on the

investigation of the micromechanical features of the minimum

dry density test.

5 ACKNOWLEDGEMENTS

The suggestion Tom Lunne, the help of Tóth Ádám és Tóth

Szabina, the support of the National Research Fund Jedlik

Ányos NKFP B1 2006 08 and the Norwegian research fund

HU-0121 are greatly acknowledged.

6 REFERENCES

Imre, E; Lőrincz, J; Trang, Q.P; Fityus, S. Pusztai, J; Telekes, G;

Schanz, T. (2009) Some dry density transfer function for sands.

Invited paper. KSCE Journal of Civil Engineering 13(4):257-272.

DOI 10.1007/s12205-009-0257-7

Imre E, Fityus S, Keszeyné E, Schanz T (2011) A Comment on the

Ratio of the Maximum and Minimum Dry Density for Sands.

Geotechnical Engineering 42(4) pp. 77-82.

Imre E, Gerendai, E; Lins, Y; Schanz T (2012) A Comment on the dry

density standards. Geotechnical Testing (submitted).

Szalkai, R. (2012) The result of the minimum

–

maximum dry density

test on 182 soil samples. Student research project (manuscript).

Lőrincz, J (1986). Grading entropy of soils Doctoral Thesis, Technical

Sciences, TU of Budapest.

Kabai, I. (1968). The compactibility of sands and sandy gravels. Acta

Technica Acad. Sci. Hung., 113-124.

Kabai, I. (1972). Relationship between the grading curve and the

compactibility. University doctoral thesis TU of Budapest, Hungary

(in Hungarian).

Kabai, I. (1974). The effect of grading on the compactibility of coarse

grained soils. Periodica Polytechnica.18 (4) 255-275.

Leussink, L.H. and Kutzner, Ch (1962) Laboratoriumversuch zur

Ferstellung der dichtesten Lagerung korniger Erdstoffe. Verüöff.

Des Inst. F. Bodenmech. Techn. Hochschule Frid. In Karlsruhe.

Lunne, T; Robertson, P.K.; Powell, J.J.M. (1992). Cone Penetration

testing. Blackie Academic & Professional.

Mayne P.W. and Kulhawy F. H. (1992). Calibration Chamber database

and boundary effects corrections for CPT data. Proc. On

Calibration Chamber Testing, New York, 1991, 257-54, Elsevier.

Rétháti, L. (1988). Probabilistic solutions in geotechnics Elsevier,

Akadémiai K. Amsterdam.

Poulos, S.J., Hed, A (1973) Density Measurements in a Hydraulic Fill.

Evaluation of Relative Density and its Role in Geotechnical

Projects Involving Cohesionless Soils. ASTM STP523. p 402-424.