355

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Table 3. Average values of n and K for relatively rounded and relatively

angular rockfill materials, compared with typical values for loose and

dense sands

Type of

Materials

Relatively

Angular

Relatively

Rounded

Loose

Sand

Dense

Sand

n

0.085

0.29

0.65

0.54

K

2004

700

300

2000

The main factor responsible for the comparatively lower

(compared with sands) average values of n for the rockfill

materials (especially the angular ones) is particles breakage

which happens during both compression and shearing of the

materials.

A

c

cording to Eq. 4, n represents the exponential effect of

σ

3

on E

i

. As particle breakage in rockfill materials is far more than

in sands, the average n value of rockfill materials is much less

than that of sands. Materials with higher degrees of angularity

suffer more particle breakage and therefore, they have lower

values of n.

The modulus number (K in Eq. 4) for the studied rockfill

materials takes values ranging widely from 53 to 36×10

9

. The

very high values of K correspond to negative values of n.

4 VARIATION OF E

i

AND

φ

WITH CONFINING

PRESSURES (

σ

3

)

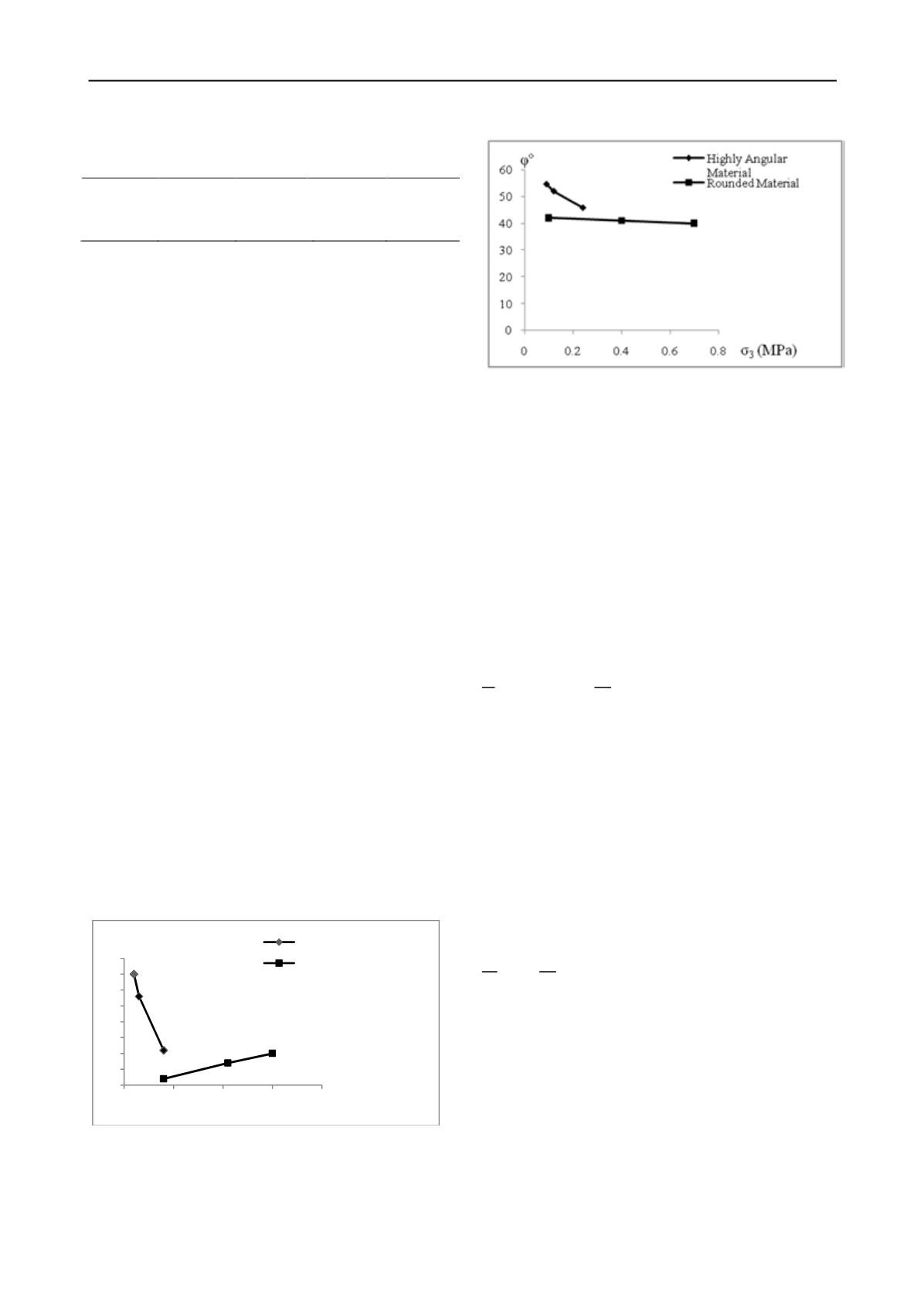

Figure 3 shows the variations of E

i

with

σ

3

while shown in

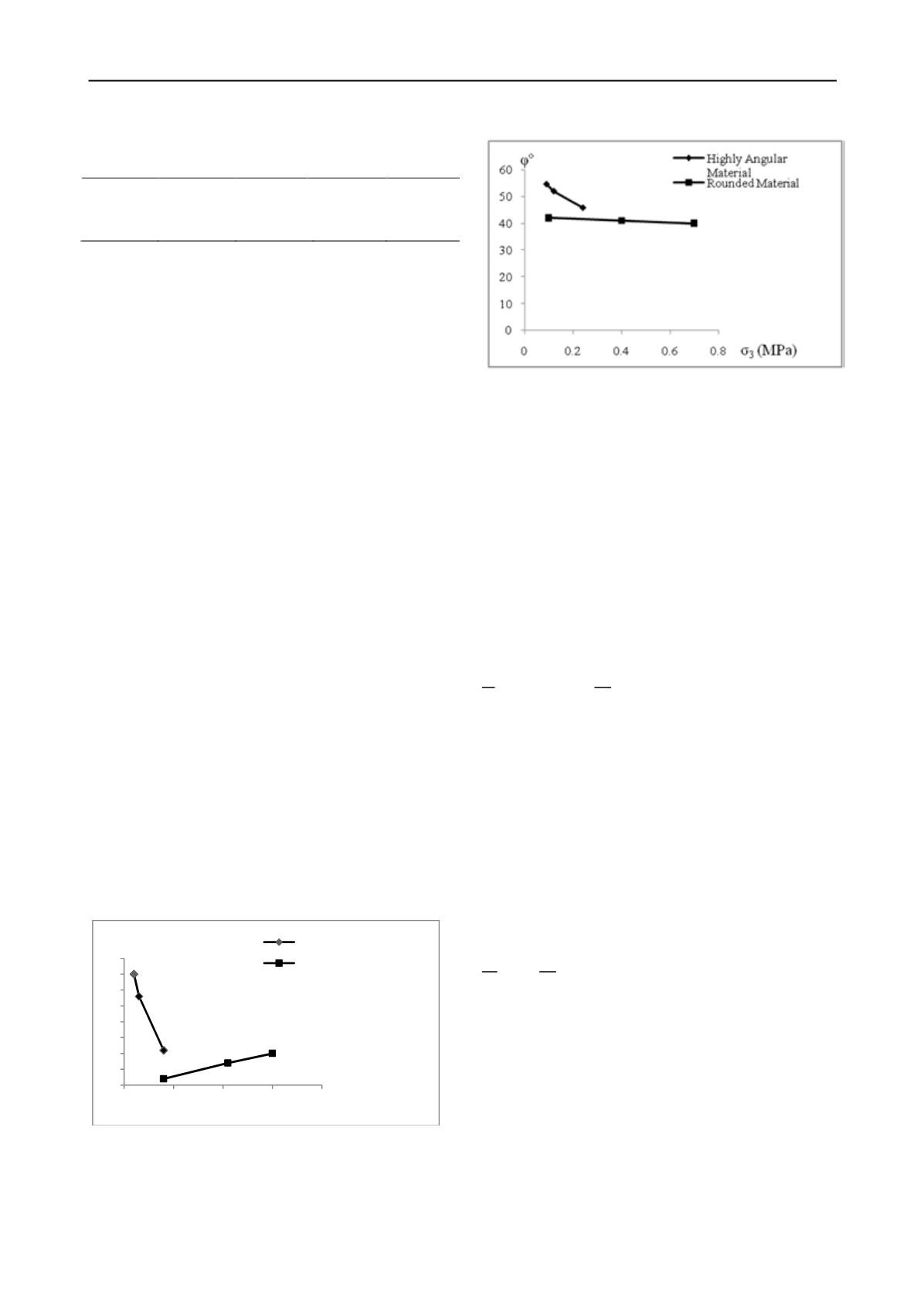

Figure 4 is the variations of

φ

with

σ

3

for one of the highly

angular and one of the rounded materials which are studied in

this paper. As Figure 3 shows, because of massive particle

breakage, the increasing of

σ

3

has resulted in the reduction of E

i

for the highly angular rockfill material, while E

i

has increased

with a gentle slope with the increase of

σ

3

for the rounded

rockfill material. Moreover, the rate of reduction of

φ

with the

increase of confining pressure is much more for the highly

angular material than for the rounded material, as presented in

Figure 4.

The above trends of variations were obvious more or less in

the behavior of the rest of the materials. Our studies on the

behavior of the materials showed that the following factors have

major effects on the rate of particle breakage:

- Shape of particles: angular particles undergo more

breakage.

- Mineralogy: particles of weaker materials break more.

- Size of particles: coarse particles are more vulnerable to

breakage.

- Coefficient of Uniformity (C

u

): A lower C

u

, causes a higher

rate of particle breakage.

Figure 3. Variations of E

i

with

σ

3

for typical rounded and highly angular

rockfill materials

Figure 4. Variations of

φ

with

σ

3

for typical rounded and highly angular

rockfill materials

It should be mentioned that according to Equation 4, the

particle breakage phenomenon affects the tangential

deformation modulus (E

t

) of rockfill materials by both "n" and

"φ "

.

The above conclusions strongly suggest that the variations of

deformation modulus of rockfill materials with confining

pressure should be taken into account in deformation analyses

of rockfill structures.

5 CORRELATION BETWEEN E

i

AND

φ

WITH

σ

3

This study on the triaxial testing results of the rockfill materials

led to two correlations between E

i

and

φ

with

σ

3

. They are as

follows:

∆

0

α log

1

∆

3

3 0

(5)

where

∆φ

= reduction of internal friction angle;

φ

0

= internal

friction angle corresponding to

σ

30

;

σ

30

= initial confining stress,

which is usually the minimum confining stress in triaxial

testing;

∆σ

3

= confining pressure increase; and

α

= a coefficient

depending on shape of particles, coefficient of uniformity (C

u

),

and confining pressure increment ratio (

∆σ

3

/

σ

30

).

Considering the studied rockfill materials,

α

ranges between

0.051 and 0.59 for the relatively angular materials and between

0.046 and 0.42 for the relatively rounded materials.

It implies that

α

for the rounded materials are generally less

than that for the angular ones; this represents the lower particle

breakage potential for the rounded materials.

The relationship for variation of E

i

with

σ

3

is suggested, as

follows:

∆

0

β

∆

3

3 0

(6)

where

∆

E

i

= changes in initial elasticity modulus; E

i0

=initial

elasticity modulus corresponding to

σ

30

; and

β

= a coefficient

depending on particle shapes, uniformity coefficient (C

u

), and

∆σ

3

/

σ

30

in triaxial compression shearing.

For the relatively angular materials,

β

was calculated as

-2.65

≤

β ≤

3.71 and for the relatively rounded materials as

-1.14

≤

β ≤

5.50. It is observed that the range of positive values

of

β

, which implies the increase of E

i

with

σ

3

, for the relatively

angular materials are smaller than the similar range for the

rounded materials (3.71 versus 5.50). For the range of negative

values of

β

, which implies the decrease of E

i

with

σ

3

, the trend

is opposite (-2.65 versus -1.14). The above observation is

logical concerning comparatively higher particle breakage and

its reductive effect on E

i

in the relatively angular materials.

0

50

100

150

200

250

300

350

400

0

0,5

1

1,5

2

Highly Angular Material

Rounded Material

E

i

(MPa)

σ

3

(MPa)