347

Technical Committee 101 - Session II /

Comité technique 101 - Session II

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

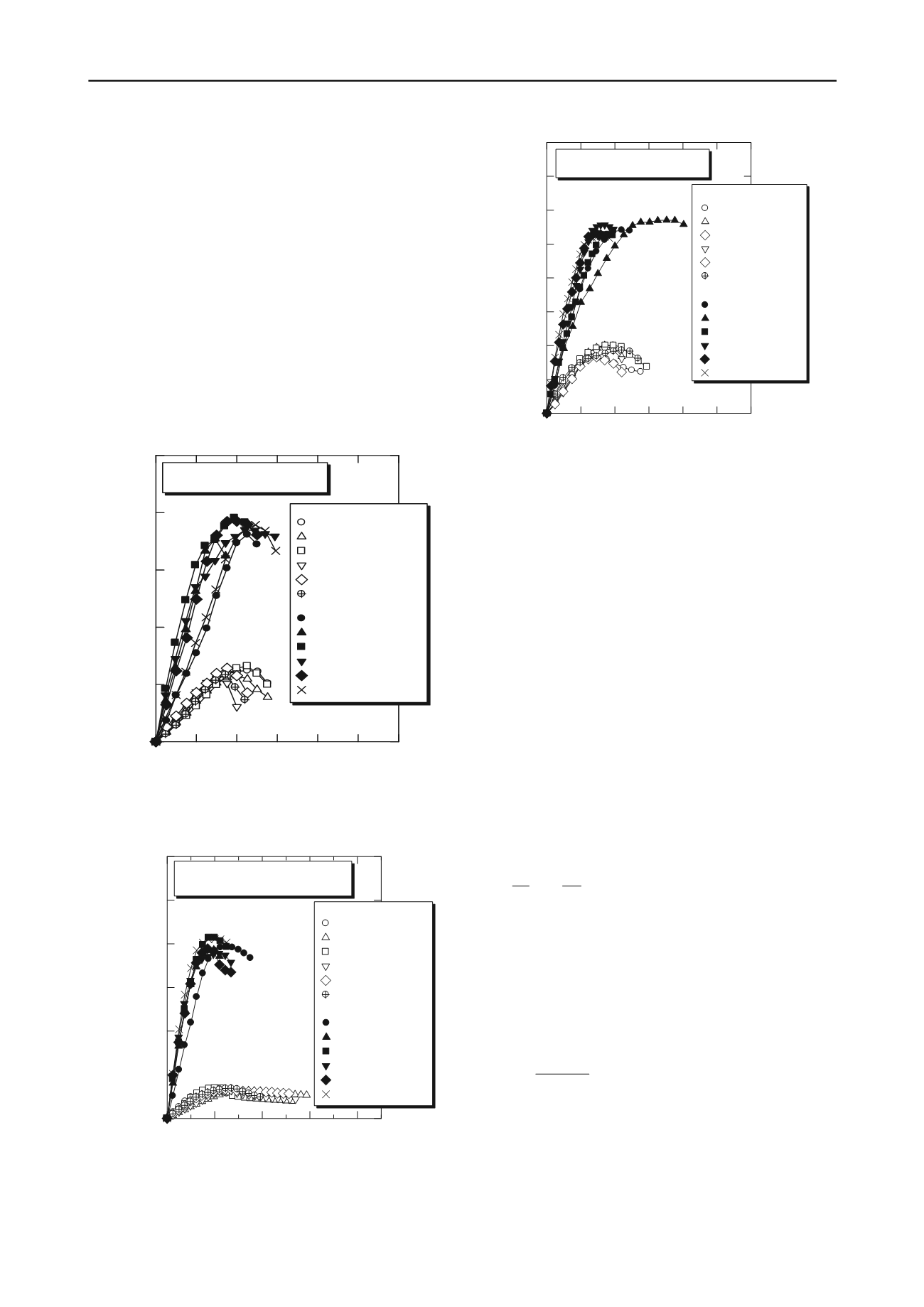

Figures 3 to 5 show the stress~strain relationships in

unconfined compression tests of samples with different air

contents and cement contents but with the same

V

/

C

values of

30 and 10, at 14 days of curing. Figure 3 is for the lightweight

cemented kaolin at water content of 88%. Figure 4 is for the

lightweight cemented Bangkok clay at water contents of 136%.

Figure 5 is for the lightweight cemented bentonite at water

contents of 170%. It is noted that as

V

/

C

decreases, the

cementation bond strength increases and hence strength. The

lightweight cemented samples with the same void/cement

exhibit the similar stress-strain behavior. To conclude, the

V

/

C

controls compressive strength and compression characteristic in

pre-yield state for a particular water content, while the unit

weight does not, which is different from natural clays. The

fabric (arrangement of clay particles, clusters and pore spaces)

reflected from both air foam content and water content is taken

into consideration by the void volume while the inter-particle

forces (levels of cementation bond) are governed by the input of

cement (cement volume).

0 0.5 1.0 1.5 2.0 2.5 3.0

0

200

400

600

800

1000

A

c

=0%,C =73.3 kg/m

3

A

c

=10%,C =76.39 kg/m

3

A

c

=20%,C =79.5 kg/m

3

A

c

=30%,C =82.7 kg/m

3

A

c

=40%,C =85.8 kg/m

3

A

c

=50%,C =88.96 kg/m

3

A

c

=0%,C =219.7 kg/m

3

A

c

=10%,C =229.2 kg/m

3

A

c

=20%,C =238.6 kg/m

3

A

c

=30%,C =248.0 kg/m

3

A

c

=40%,C =257.44 kg/m

3

A

c

=50%,C =266.9 kg/m

3

V/C =30

V/C =10

Lightweight cemented kaolin

w

=88%

Axial stress (kPa)

Axial strain (%)

Figure 3. Stress-strain relationship of air-cement-admixed kaolin at

w

=

88%.

0

1.0

2.0

3.0

4.0

0

500

1000

1500

2000

2500

3000

A

c

=0%,C =81.9 kg/m

3

A

c

=10%,C =84.2 kg/m

3

A

c

=20%,C =86.4 kg/m

3

A

c

=30%,C =88.7 kg/m

3

A

c

=40%,C =91.0 kg/m

3

A

c

=50%,C =93.3 kg/m

3

A

c

=0%,C =245.6 kg/m

3

A

c

=10%,C =252.4 kg/m

3

A

c

=20%,C =259.3 kg/m

3

Axial stress (kPa)

Lightweight cemented Bangkok clay

w

=136%

Axial strain (%)

A

c

=30%,C =266.1 kg/m

3

A

c

=40%,C =273.0 kg/m

3

A

c

=50%,C =279.8 kg/m

3

V/C =30

V/C =10

Figure 4. Stress-strain relationship of air-cement-admixed Bangkok clay

at

w

= 136%.

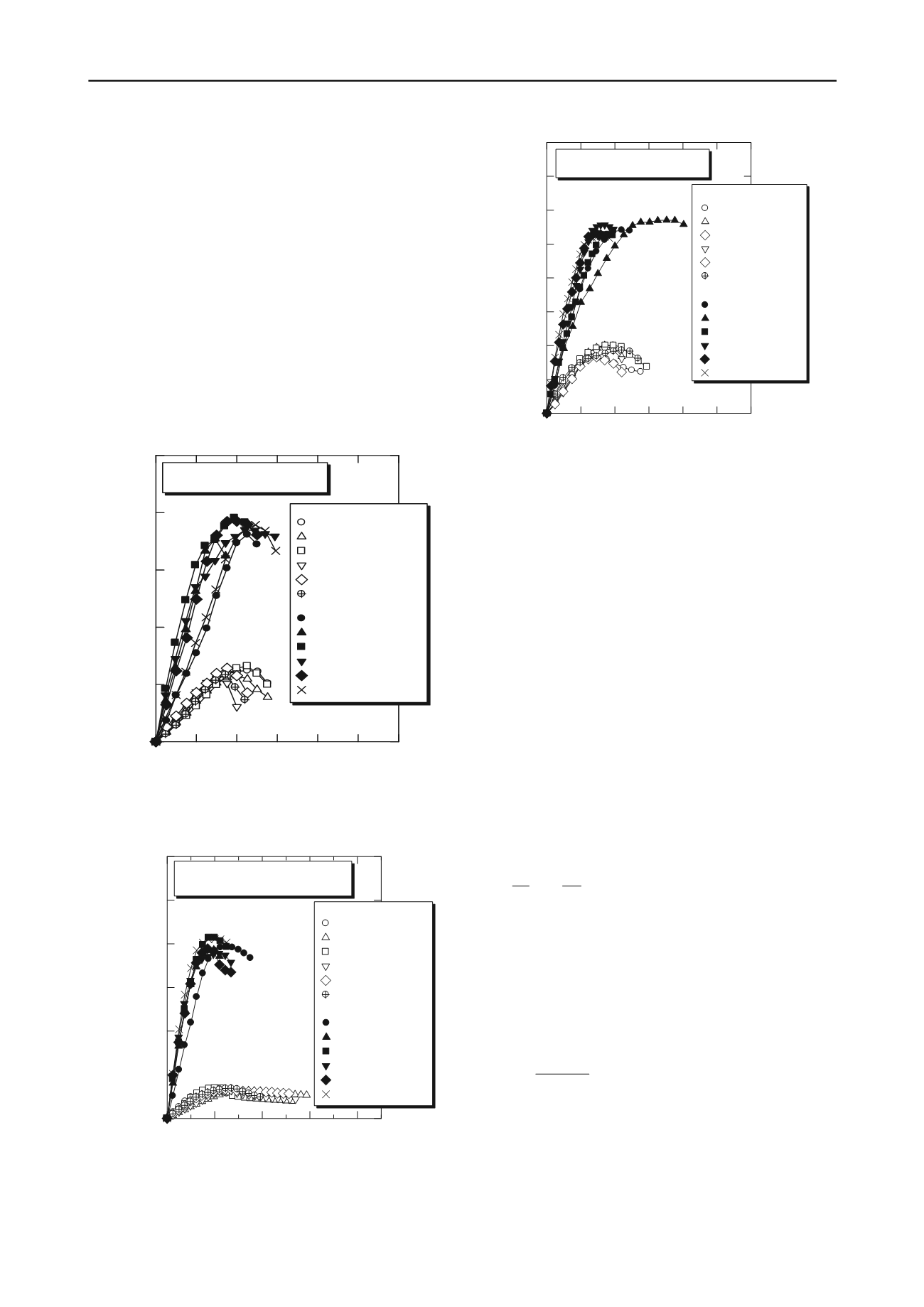

0 0.5 1.0 1.5 2.0 2.5 3.0

0

500

1000

1500

2000

2500

3000

3500

4000

A

c

=0%,C =85.1 kg/m

3

A

c

=10%,C =87.0 kg/m

3

A

c

=20%,C =89.0 kg/m

3

A

c

=30%,C =91.0 kg/m

3

A

c

=40%,C =92.9 kg/m

3

A

c

=50%,C =94.9 kg/m

3

A

c

=0%,C =255.2 kg/m

3

A

c

=10%,C =261.1 kg/m

3

A

c

=20%,C =266.9 kg/m

3

Axial stress (kPa)

Lightweight cemented bentonite

w

=170%

Axial strain (%)

A

c

=30%,C =272.8 kg/m

3

A

c

=40%,C =278.7 kg/m

3

A

c

=50%,C =284.6 kg/m

3

V/C =30

V/C =10

Figure 5. Stress-strain relationship of air-cement-admixed bentonite at

w

= 170%.

Figures 1 to 5 show the advantage of using air form to

produce the lightweight cemented clay. The strength reduction

is observed when the void increase by air form due to the

increase in contact area per cementation bond. However, the

role of air content on the strength development is less

significant than that of cement and water. This is because the

hydration is strongly depended on the water/cement ratio in the

mix. In other words, by using the air form, the unit weight is

significantly reduced with less strength reduction.

Because the

V

/

C

is the prime parameter governing the

engineering properties in elastic range (at low effective

confining stress), it is possible to develop a relationship

between strength and

V

/

C

for a particular curing time. Figure 6

shows the relationship between strength and

V

/

C

at 7 days of

curing of the lightweight cemented Bangkok clay as an example

to guarantee the applicability of the

V/C

. The unique

relationship between strength and

V/C

can be found for a given

initial water content at different cement contents and air

contents. Based on the experimental observations (5 <

V

/

C

< 40

and 7 days of curing), it is possible to advance the following

identity:

1

2

1

2

Constant

V V

C C

(1)

Once the void/cement ratio is fixed in the field, if the air

content (void volume) is changed to achieve the required unit

weight, the cement content can be estimated from Eq.(1) to

attain the same strength and compressibility characteristics. For

a mix design purpose, the relationship between strength and

V/C

at a certain water content is advanced on the basis of Abrams’

law (1918):

/

u

B

A q

V C

(2)

where

q

u

is the unconfined compressive strength,

V/C

is the

void/cement ratio, and

A

and

B

are constants. This equation

when

A

c

= 0 yields the same equation proposed by Horpibulsuk

et al. (2011a, b and 2012a). The

A

-value is dependent upon the

clay type, curing time and air content. As the water content

increases, the

A

-value decreases. The

B

-value is practically

constant and equal to 1.26 to 1.29, which is the typical values