346

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

based on the USCS. Bentonite was composed of 0% sand, 50%

silt and 50% clay. The specific gravity was 2.63. The liquid and

plastic limits were 106% and 60%, respectively. It was

classified as inorganic clay of high plasticity (CH).

The clay paste was passed through 2-mm sieve for removal

of shell pieces and other bigger size particles, if present. The

water content was adjusted to (2-5) times liquid limit. This

intentional increase in water content is to simulate the clay

slurry with high flow ability for pumping into the construction

sites. Even with very high water content up to 5 times liquid

limit, all tested clays still have viscosity with low magnitude,

indicating that the sorting of the grain size does not occur. The

clays were mixed with air foam to attain air contents,

A

c

,

between 10 and 100% by volume of the clay-water-air mixture.

This mixture was then thoroughly mixed with cement for 10

min. The cement content,

C

, was varied from 150 to 400 kg/m

3

of the mixture. To verify the

V

/

C

as a prime parameter, the

cement content and air content were varied to attain the

V

/

C

values of 30 and 10. Such a uniform paste was transferred to

oedometer rings as well as to cylindrical containers of 50 mm

diameter and 100 mm height, taking care to prevent any air

entrapment. After 24 hours, the cylindrical samples were

dismantled. All the cylindrical samples and oedometer samples

were wrapped in vinyl bags and they were stored in a humidity

room of constant temperature (20

2

C) until lapse of different

curing times as planned. Oedometer tests were carried out after

14 days of curing. Unconfined compression (UC) tests were run

on samples after 7 and 14 days of curing. The rate of vertical

displacement in UC tests was 1 mm/min. Both tests were

performed according to the American Society of Testing and

Materials (ASTM) standards.

3 VOID/CEMENT RATIO,

V

/

C

In cement admixed clay, the clay-water/cement ratio hypothesis

(Horpibulsuk and Miura, 2001; Horpibulsuk et al., 2005; and

Miura et al., 2001) is stated as follows:

"For given cement admixed clay, age and curing

conditions, the strength is determined exclusively by the

ratio of clay-water content to the cement content in the

mix. Strength is independent of clay-water content and

cement content in the mix."

As an analogy, the parameter that can be identified for

lightweight cemented clays is void/cement ratio,

, which is

the volume of void to the volume of cement in the mix. The

parameter can be simply determined using four phase diagram

of soil, water, air and cement (Horpibulsuk et al., 2012b). To

obtain the same value of

for a particular clay water

content, it is possible to vary the amount of air foam or cement

or both as the case might be. In order to examine up to what

extent the applicability of

is valid, the air foam content is

varied over a wide range (

A

c

= 10-50% of clay volume) in this

study.

/

V C

/

V C

/

V C

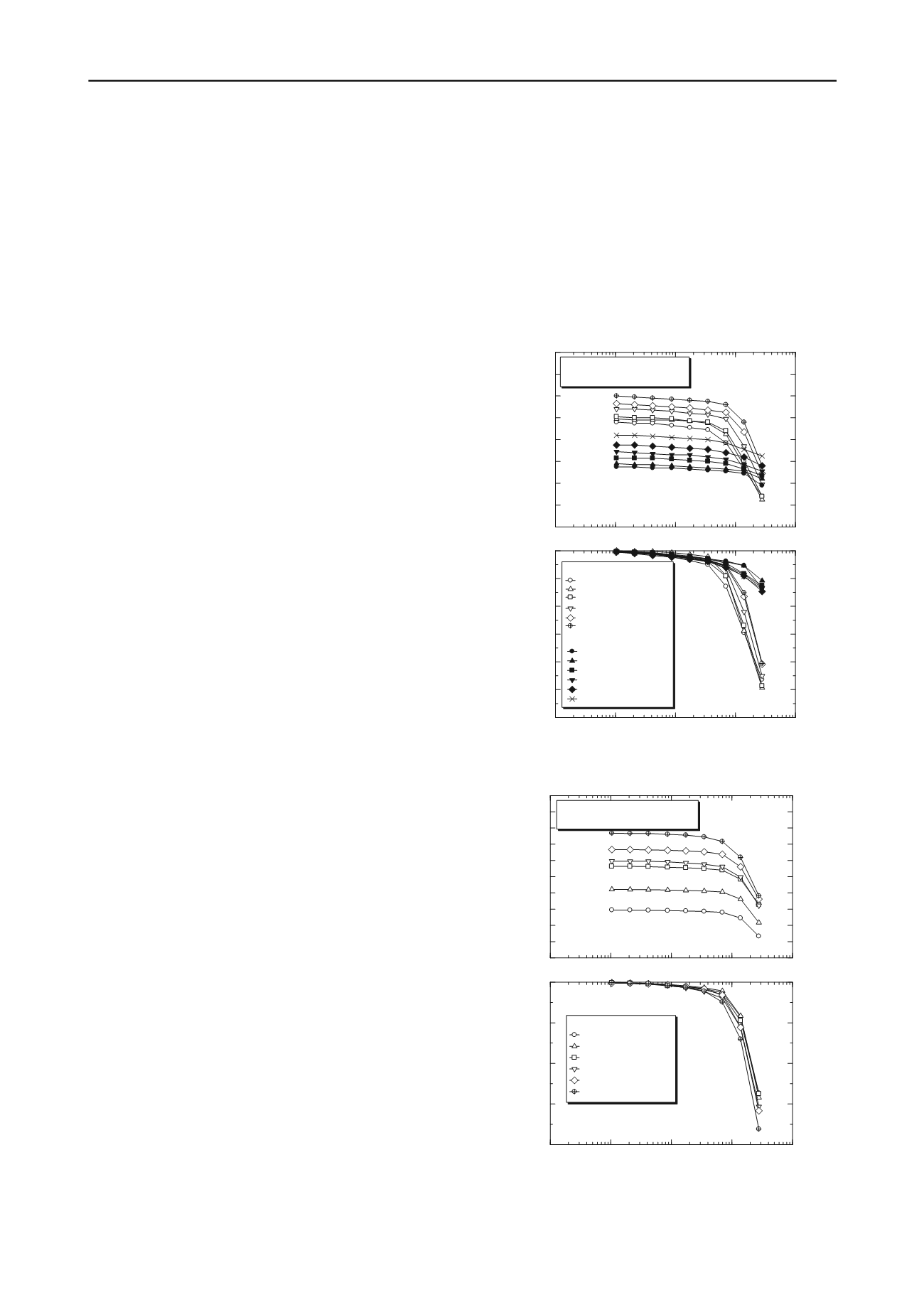

4 TEST RESULTS

The role of

V/C

on the compressibility is shown in Figures 1

and 2 for lightweight cemented kaolin and bentonite samples

with the same

V/C

values but with different combinations of

cement content and air content. The samples were made up

from six conditions of air content namely, 0, 10, 20, 30, 40 and

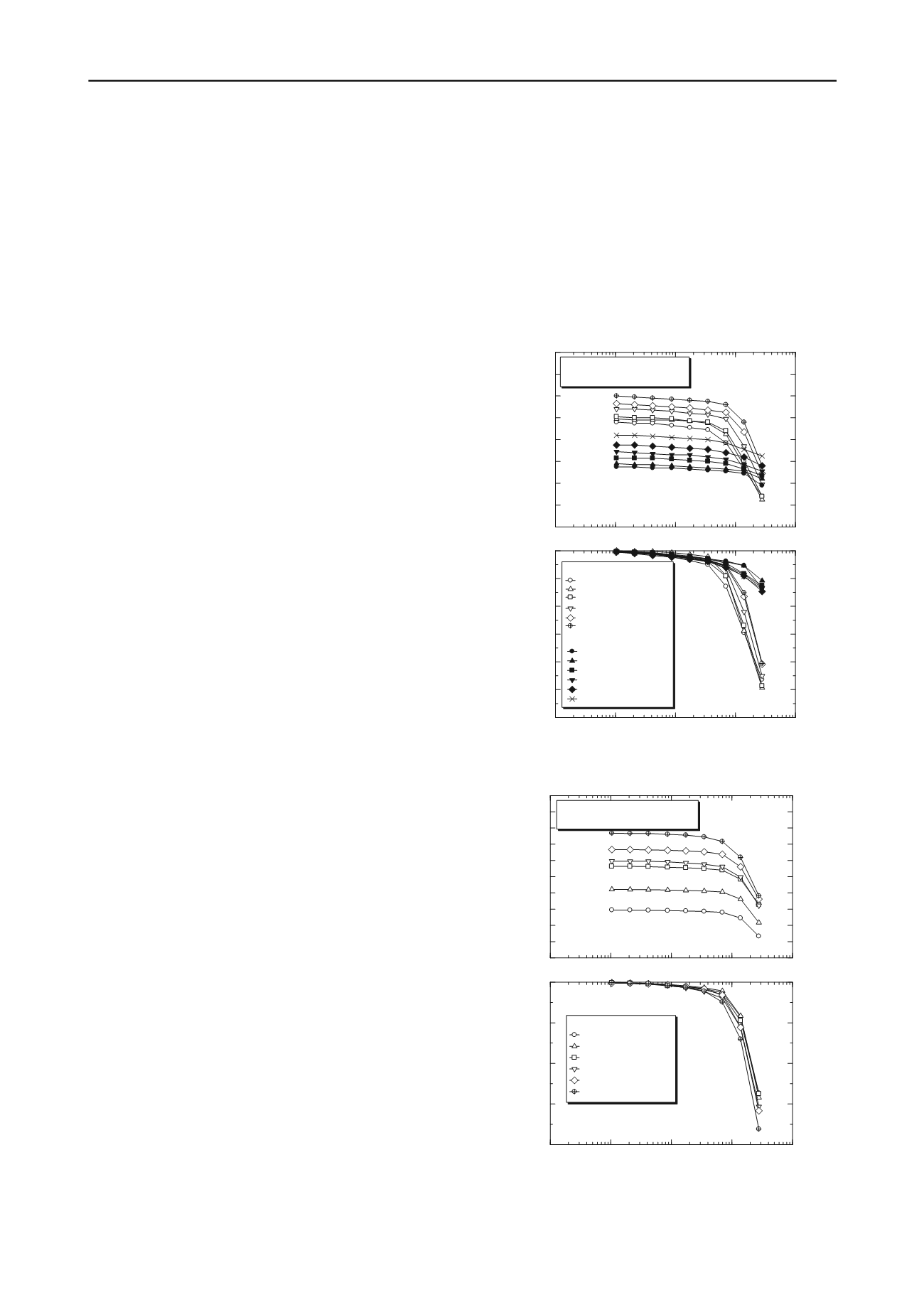

50%. Figure 1 shows the compressibility of lightweight

cemented kaolin at water content of 88%. Figure 2 shows the

compressibility of lightweight cemented bentonite at water

content of 280%. They show the (

e

, log

v

) and (

v

, log

v

)

relations of the samples at

V/C

values of 30 and 10 after 14 days

of curing. The resistance to compression prevails up to a certain

stress level beyond which the sample experiences increase in

compression. This stress level is identified as yield stress

(Horpibulsuk et al., 2005). It does not represent pre-

consolidation pressure because the cemented clay was not being

subjected to any stress history. The (

v

, log

v

) relationship is

plotted so as to take care of the effect of the difference in void

ratio for the vertical stresses less than the yield stress. For a

certain water content, the yield stress and the deformation

behavior in pre-yield stress of all samples with identical

V/C

values are practically the same. This implies that

V/C

is a prime

parameter governing the compressibility in pre-yield state. The

yield stress increases as the

V

/

C

value decreases. The samples

with higher air content are stable at higher void ratios. Beyond

the yield stress, drastic compression occurs as vertical pressure

increases due the breakup of cementation bond (Horpibulsuk et

al., 2004a, Horpibulsuk et al., 2010; Liu and Carter, 1999, 2000

and 2002; and Suebsuk et al., 2010 and 2011).

10

0

10

1

10

2

10

3

10

4

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

Lightweight cemented kaolin

w

=88%

Void ratio,

e

Effective vertical stress,

'

v

(kPa)

10

0

10

1

10

2

10

3

10

4

0

5

10

15

20

25

30

Volumetric strain,

v

(%)

A

c

=10%, C =76.4 kg/m

3

A

c

=20%, C =79.5 kg/m

3

A

c

=30%, C =82.7 kg/m

3

A

c

=40%, C =85.8 kg/m

3

A

c

=50%, C =89.0 kg/m

3

A

c

=0%, C =219.7 kg/m

3

A

c

=10%, C =229.2 kg/m

3

A

c

=20%, C =238.6 kg/m

3

A

c

=30%, C =248.0 kg/m

3

A

c

=40%, C =257.4 kg/m

3

A

c

=50%, C =266.9 kg/m

3

A

c

=10%, C =73.3 kg/m

3

V/C =30

V/C =10

Figure 1. Compressibility of air-cement-admixed kaolin at

w

= 88%.

10

0

10

1

10

2

10

3

10

4

2

3

4

5

6

7

8

9

10

11

12

Lightweight cemented bentonite

w

=280%

Void ratio,

e

Effective vertical stress,

'

v

(kPa)

10

0

10

1

10

2

10

3

10

4

0

10

20

30

40

Volumetric strain,

v

(%)

A

c

=10%, C =93.0 kg/m

3

A

c

=20%, C =94.3 kg/m

3

A

c

=30%, C =95.6 kg/m

3

A

c

=40%, C =96.9 kg/m

3

A

c

=50%, C =98.2 kg/m

3

A

c

=0%, C =91.8 kg/m

3

V/C =30

Figure 2. Compressibility of air-cement-admixed bentonite at

w

=

280%.