268

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

foundation punch-through failure depends on the operative

friction angle and associated dilation angle, both of which

reduce with increasing stress level.

This paper reports the results from a series of basic

characterisation tests conducted on reconstituted samples of

carbonate sand to understand its behaviour. Centrifuge tests

were also carried out on spudcan foundations penetrating four-

layer deposits, with an interbedded carbonate or silica sand

layer for direct comparison.

Table 1. Values of

Q

and

crit

derived from triaxial compression tests

(after Randolph et al. 2004, InSafeJIP 2010).

Sand

Mineralogy

Q

crit

Reference

Ticino

Siliceous

10.8

33.5

Toyoura

Quartz

9.8

32

Hokksund Siliceous

9.2

34

Jamiolkowski

et al. (2003)

Mol

Quartz

10

31.6

Yoon (1991)

Kenya

Calcareous 8.5

40.2

Quiou

Calcareous 7.5

41.7

Jamiolkowski

et al. (2003)

2 STRESS-STRAIN BEHAVIOR

Simple shear tests with a Berkeley type apparatus were

performed on uncemented skeletal carbonate sand recovered

from the seabed of Australian North-West Shelf (NWS).

Particles smaller than 75 μm and larger than 2.36 mm were

removed by washing and sieving prior to testing. The achieved

median grain size and coefficient of uniformity were

d

50

= 0.22

mm and

C

u

=

2.3, respectively. The high grain angularity and

intra-particle void resulted in a high void ratio with minimum

and maximum value of 0.91 and 1.36 respectively.

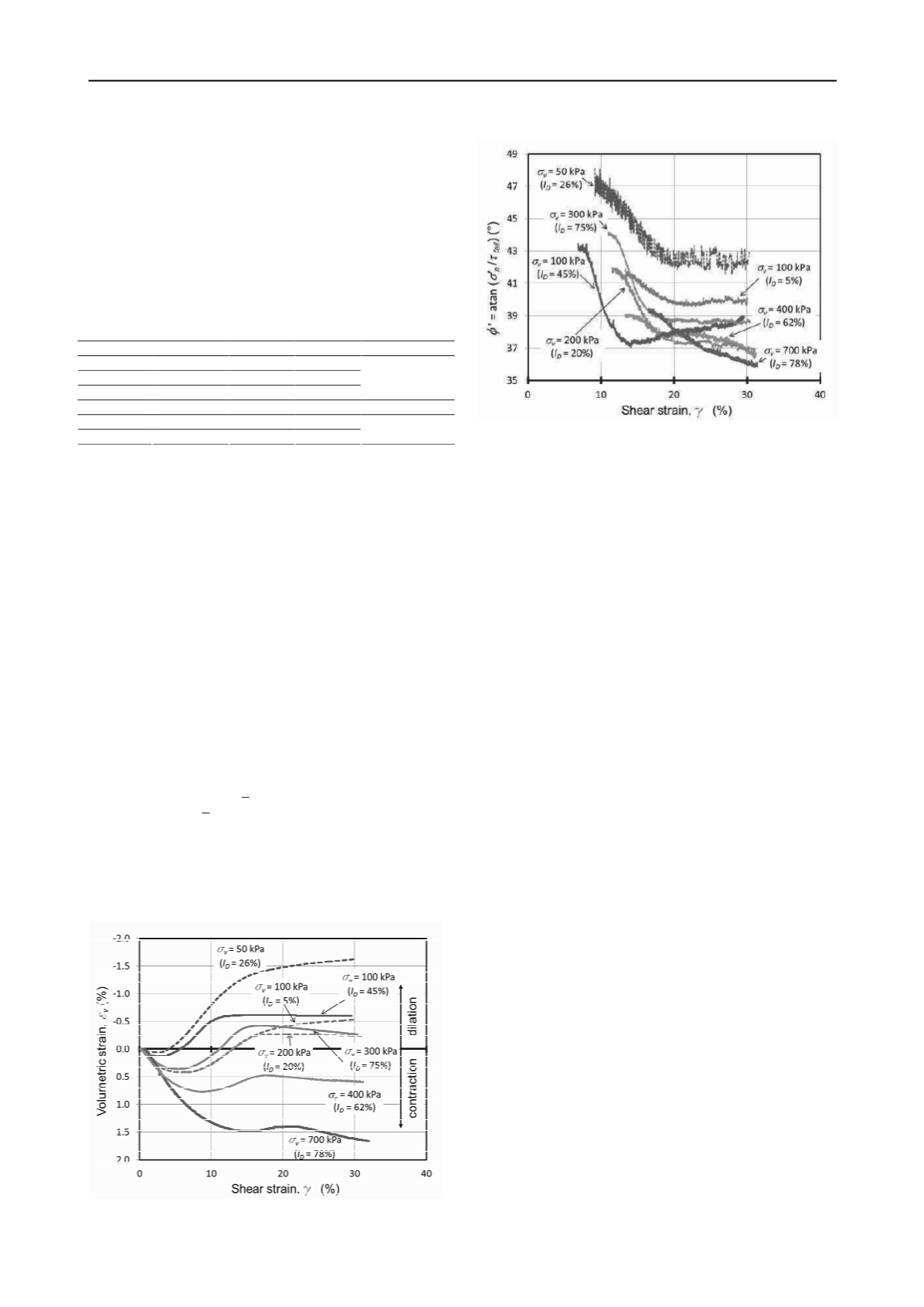

Drained tests with a lateral stress ratio

K

= 0.4 were

performed on loose and medium dense sand to obtain the stress-

strain behaviour. The results are shown in Figures 1 and 2,

highlighting a strong dependency of the volumetric dilatancy on

the confining stress. The values of relative densities (

I

D

) shown

in the figures represent the condition just before shearing.

Dilative volume change occurred even in loose sand at a vertical

stress

v

= 200 kPa (see Figure 1). This dilative response is not

unusual owing to the particle angularity and interlocking. For

most tests, shearing ended in dilative volume state, except two

at higher stresses with

v

> 400 kPa. Interestingly, for dense

sand subjected to

v

> 300 kPa, dilative response at intermediate

strains turned to contraction close to the end of shearing,

indicating the influence of continual particle breakage. A

transient dilation at the highest stress of

v

= 700 kPa was also

noticed at shear strain levels of 15 to 20%.

The transition from dilative to contractive behaviour

occurred at a lower stress level,

v

< 400 kPa or mean stress

p

< 240 kPa, compared to silica sand.

Figure 1. Volumetric change of carbonate sand in drained simple shear

test with lateral stress ratio

K

= 0.4.

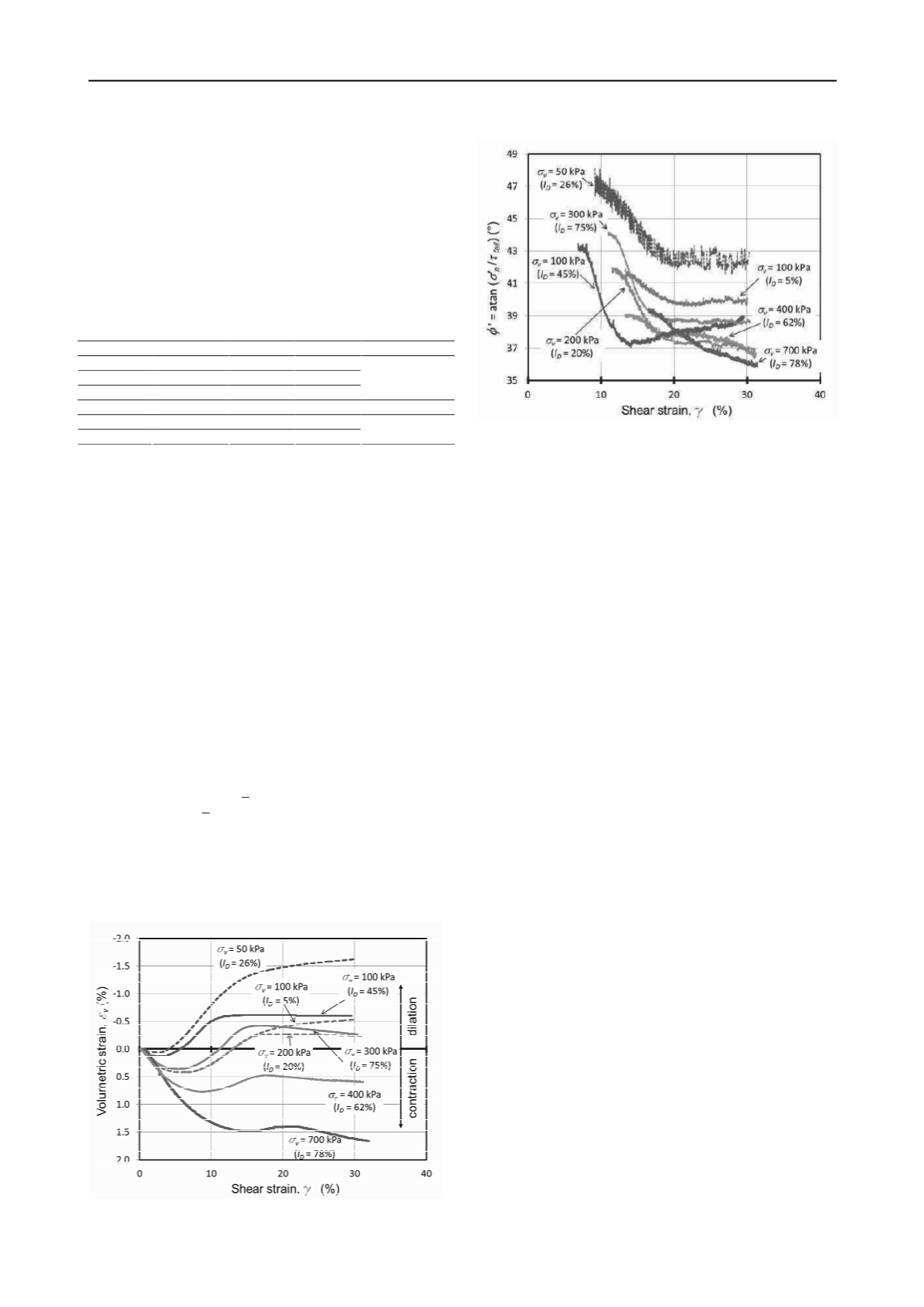

Figure 2. Effective friction angle of carbonate sand in drained simple

shear test with lateral stress ratio

K

= 0.4 (post-peak condition only).

Peak dilation angle

peak

can be estimated using Bolton’s

(1986) empirical correlation

R

peak

crit

peak

mI

8.0

(1)

1

ln

p Q I

I

D R

(2)

where

m

is a constant, taken as 3 for failure under triaxial or

general loading conditions and 5 under plane-strain conditions,

and

I

R

is the relative dilatancy. Some reported values for

Q

for

siliceous grains range from 9.2 to 10.8, while lower values of

7.5 to 8.5 are reported for calcareous grains (see Table 1).

Assuming that the dilation angle of the NWS carbonate sand

turned to zero at a mean stress

p

= 240 kPa, a value for

Q

can

be calculated as 5.5.

The friction angle was interpreted using the AG method

(Joer et al. 2011) by considering the actual observed shear

plane. The normal and shear stresses were calculated for the

diagonal shear plane and used to determine the friction angle.

This method gave more realistic values compared to the

traditional interpretation, which assumes a complementary shear

stress on the vertical sample boundary. The calculated peak

friction angle

'

peak

ranges from 39.5° to 48°, while the residual

friction angles

'

res

from 35.8° to 42.9° (see Figure 2). No

uniform steady state can be identified, rather a tendency of

decreasing

'

res

with increasing confining stress is evident.

3 EFFECT OF PARTICLE DEGRADATION

In carbonate sands, high crushability and compressibility are led

by the high intra-particle porosity, as discussed previously.

Datta et al. (1980) reported the effect of grain crushing during

shearing and found direct correlations between crushing and

reduction of maximum principal effective stress ratio, change

from dilative to contractive behaviour, more plastic stress-strain

relation, and increase of failure strain.

Golightly and Hyde (1988) performed comprehensive

isotropic drained triaxial (CID) tests on three different skeletal

carbonate sands, all with a relative density of 97%. They

reported results in terms of friction angle

f

, calculating

according to

f

=

peak

-

, as shown in Figure 3. The dilation

angles of the tested carbonate sands were found lower than

those of the silica sand. The critical confining stress at which

dilation was suppressed was also shown to be very low

compared to silica sand. For instance, the dilation angle of Dogs

Bay sand, which is mainly composed of skeletal mollusc

fragments, decreased to zero at a confining stress of only 370

kPa. The siliceous Leighton Buzzard sand, on the other hand,

has a constant dilation angle of around 9° to 10° for all tested

confining stresses (< 1000 kPa).