258

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

because the plastic strain increment does not related to the stress

increment as described before. The result of the proposed model

describes properly the strain rate effects known experimentally.

Figure 7 shows the results of (a) creep behavior after loading

with constant stress rate, and (b) stress relaxation behavior after

loading with constant strain rate (loading processes are

indicated in the interpolated diagram in each figure). Figure 8

shows the computed

e

-logt relation of conventional oedometer

test by 1D soil-water coupled finite element analysis. Here,

0

is

the initial stress, and

is the instantaneous stress increment.

It can be seen that the three models describe the well-known

consolidation behavior of normally consolidated clay including

the secondary compression.

4.2

Analysis of over consolidated clay and naturally

deposited clay by the proposed model

The non-satoionary flow surface model and the over-sress type

model described in the above section are applicable to normally

consolidated soil alone. On the ther hand, as can be seen from

the derivaton process, the proposed model is valid for over

consolidated soil and structured soil as well. In this subsection,

some applications of the poposed model to over consolidated

clay and structured clay are shown.

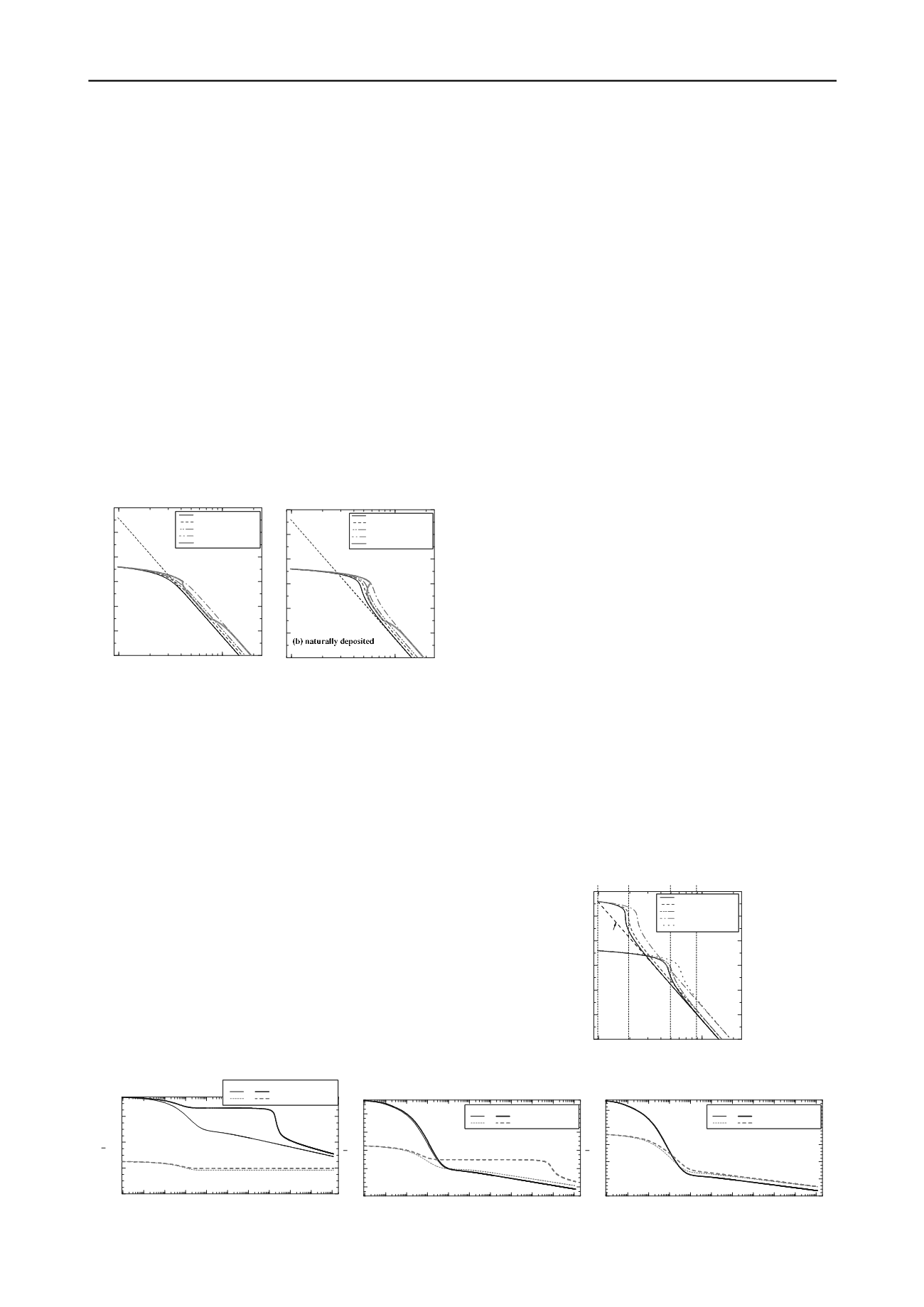

Figure 9 shows the results of one-dimensional compression

behavior of these clays in the same way as Figure 6. It can be

seen that the present model describe well the typical feature of

e

-ln

relation for these clays and the time effect such that the

quasi-yield stress becomes large with increasing strain rate and

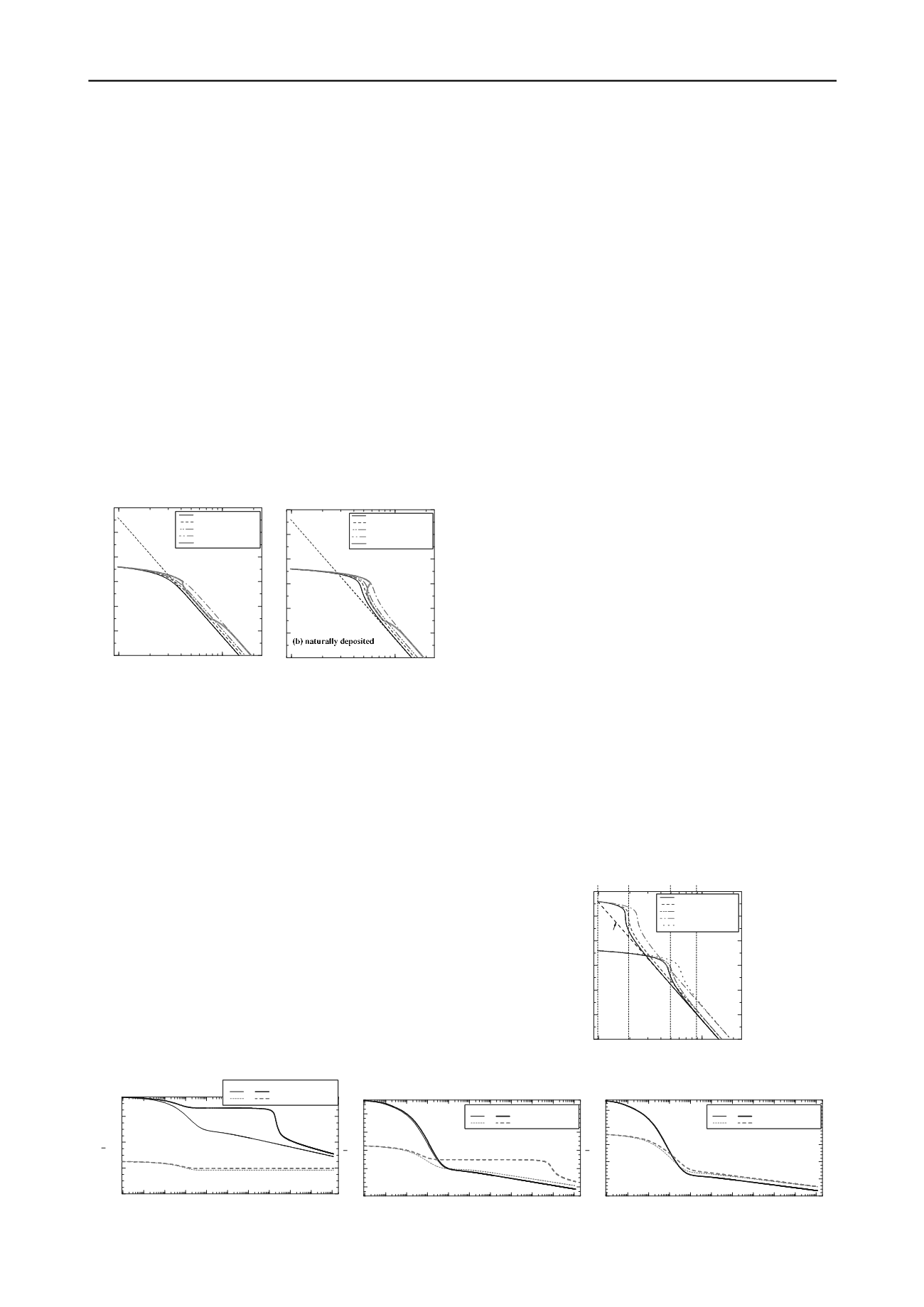

the phenomenon of isotache. Figure 10 shows the computed

results of oedometer tests on non-structured (

0

=0.0) and

structured (

0

=0.20) clays with two kinds of initial void ratios

(

0

=0.0 and 0.10), arranged with the same manner as Figure 8.

Here, thin curves and thick curves indicate ones without

bonding (

0

=0.0) and ones with bonding (

0

=0.20). Diagrams

(a), (b) and (c) shows the results of the ratio of stress increment

to initial stress:

/

0

=1, 4 and 8, respectively. It is seen from

diagrams (a) and (b) that although the behavior of the normally

consolidated structured clay (

0

=0.0) is different from that of

the normally consolidated non-structured clay under small stress

increment (

/

0

=1), there is not much difference between

them under large stress increment (

/

0

=4). On the other

hand, the behavior of over consolidated clays (

0

=0.10) is

highly influenced by the effect of structure (bonding) not under

small stress increment but under large stress increment. It is also

seen that from diagram (c) that when the stress increment is

extremely large (

/

0

=8), there is not much difference

between non-structured clay and structured clay regardless of

the initial void ratio. Figure 11 shows the stress strain relation

of these structured clays under large and small strain rate. The

delayed settlements of structured clays may occur when the

quasi-yield stress, which becomes small with decreasing strain

rate, moves through the stress of the corresponding element

(indicated by vertical dotted lines).

5 CONCLUSIONS

The feature of the ordinary viscoplastic models for clay are

explained in 1D condition for easy understanding. A new

approach to model without using ordinary viscoplasticiy is also

shown. The new model is applicable not only to normally

consolidated soil but also to over consolidated soil and naturally

deposited soil. The applicabity of these models are discussed

through the simulations of various time-dependent behavior of

clays. Using the

t

ij

concept (Nakai and Mihara 1984), the

present 1D model can be extended to 3D one (see Nakai et al.

2011b, Nakai 2012).

6 REFERENCES

Adachi T. and Oka F. 1982. Constitutive equation for normally

consolidated clays based on elasto/viscoplasticity.

Soils and

Foundations

, 22(4), 57-70.

Bjerrum L. 1967. Engineering geology of Norwegian normally

consolidated marine clays as related to settlements of buildings,

Geotechnique

, 17(2), 81-118.

Hashiguchi K. 1980. Constitutive equation of elastoplastic materials

with elasto-plastic transition.

Jour. of Appli. Mech., ASME

, 102(2),

266-272.

Mimura M. and Sekiguchi H. 1985. A review of elasto-viscoplastic

models with particular emphasis on stress-rate effect.

Proc of 20

th

Annual Meeting of JGS

, 1, 403-406 (in Japanese).

Nakai T. and Mihara Y. (1984): A new mechanical quantity for soils

and its application to elastoplastic constitutive models,

Soils and

Foundations

, 24(2), 82-94.

Nakai T., Shahin H.M., Kikumoto M., Kyokawa H., Zhang F. and

Farias, M.M. 2011a: A simple and unified one-dimensional model

to describe various characteristics of soils.

Soils and Foundations

,

51(6), 1129-1148.

Nakai T., Shahin H.M., Kikumoto M., Kyokawa H., Zhang F. and

Farias, M.M. 2011b. A simple and unified three-dimensional model

to describe various characteristics of soil.

Soils and Foundations

,

51(6), 1149-1168.

Nakai T. 2012.

Constitutive Modeling of Geomaterials: Principles and

Applications

. CRC Press.

Perzyna P. 1963. The constitutive equations for rate sensitive plastic

materials,

Quart. Appli. Math.

, 20(4), 321-332.

Sekiguchi H. 1977. Rheological characteristics of clays.

Proc. of 9

th

ICSMFE

, Tokyo, 1, 289-292.

10

2

10

3

0.55

0.6

0.65

0.7

0.75

0.8

0.85

no creep

0.002%/min

0.02%/min

2.0%/min

2.0 - 0.002 - 2.0%/min

Ideal - Drained

e

=0.0030

0

=0.10

0

=0.0

(kPa)

(a)

10

2

10

3

0.55

0.6

0.65

0.7

0.75

0.8

0.85

no creep

0.002%/min

0.02%/min

2.0%/min

2.0 - 0.002 - 2.0%/min

Ideal - Drained

e

=0.0030

0

=0.10

0

=0.20, b=40

(kPa)

Figure 9. Simulations of strain rate effect

10

-3

10

-2

10

-1

1 10 10

2

10

3

10

4

10

5

10

6

10

7

0.68

0.72

0.76

0.8

0

=0.0

0

=0.20

0

=0.000 (OCR=1.00)

0

=0.100 (OCR=2.90)

e

t (min)

H=1cm

=98kPa

=98kPa

=0.0030

b=40

(a)

10

-3

10

-2

10

-1

1 10 10

2

10

3

10

4

10

5

10

6

10

7

0.64

0.68

0.72

0.76

0.8

0

=0.0

0

=0.20

0

=0.000 (OCR=1.00)

0

=0.100 (OCR=2.90)

e

t (min)

H=1cm

=98kPa

=392kPa

=0.0030

b=40

(b)

10

-3

10

-2

10

-1

1 10 10

2

10

3

10

4

10

5

10

6

10

7

0.55

0.6

0.65

0.7

0.75

0.8

0

=0.0

0

=0.20

0

=0.000 (OCR=1.00)

0

=0.100 (OCR=2.90)

e

t (min)

H=1cm

=98kPa

=784kPa

=0.0030

b=40

(c)

Figure 10. Simulations of oedometer tests on non-structured and structured clays with different initial void ratios

10

2

10

3

0.55

0.6

0.65

0.7

0.75

0.8

0.85

e

=0.0030

0

=0.20, b=40

(kPa)

NCL

no creep

0.002%/min(

0

=0.0)

0.002%/min(

0

=0.1)

2.0%/min(

0

=0.0)

2.0%/min(

0

=0.1)

Figure 11. Stress-strain behavior of structured clays