264

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(Chow and Airey 2011) and Statnamic pile tests (Brown and

Hyde 2008) where the pile is displaced at rates of the order of 1

m/s. In these cases, rate effects cause the capacities derived

from the tests to exceed static values; an issue which is usually

dealt with by the inclusion of damping co-efficients in the

analyses. (Brown and Powell 2013) These damping co-

efficients are not always uniform throughout each test, but may

vary with strain level. This highlights the importance of

understanding the strain level dependence of rate effects in

order to improve the accuracy of dynamic testing in the field.

2 MATERIAL TESTING AND PROCEDURES

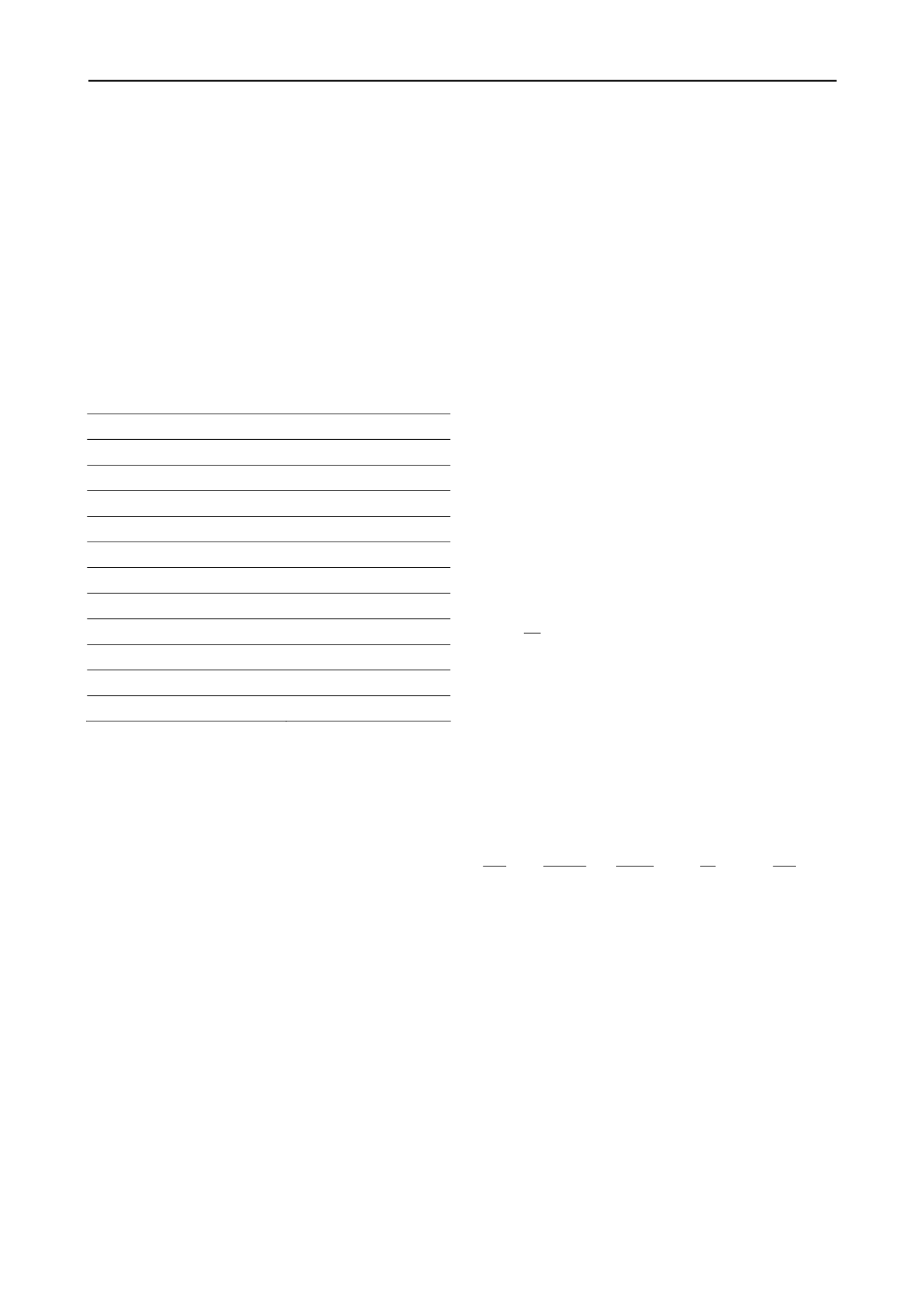

The tests were carried out on reconstituted speswhite kaolin, the

properties of which are shown in Table 1.

Table 1. Properties of the speswhite kaolin used

Property

Value

Plastic limit, w

P

(%)

32.5

Liquid limit, w

L

(%)

65.0

Plasticity index, PI (%)

32.5

Clay fraction (%)

80

Activity (%)

40.6

Specific surface area (m

2

/g)*

36.7

Permeability, k (mm/s)

#

1.17 x 10

-6

c

v

(m

2

/year)

+

23.52

MCSL

0.9

λ

0.101

N

2.678

* Determined from methylene blue spot testing

#

Determined at an effective stress of 300 kPa

+

Determined for a 100 kPa stress increment

The samples were first prepared as slurry with a moisture

content of 120 % using de-aired, de-ionised water before being

one dimensionally consolidated to an effective stress of 180 kPa

for three days. These were then trimmed to 200 mm length and

100 mm diameter to create triaxial samples. Once installed in

the triaxial apparatus, the sample was saturated to an effective

stress of 50 kPa at a back pressure of 300 kPa and then

reconsolidated to an effective stress of 300 kPa to restore

isotropic conditions. Sample drainage was facilitated by using

vertical filter paper drains on the surface of the sample,

connected to both the top and bottom drainage valves. These

were required as the use of lubricated end platens in the testing

meant that conventional drainage was not possible, and had the

additional benefit of significantly reducing consolidation times.

2.1

Testing apparatus

The tests were carried out in a GDS advanced

electromechanical dynamic triaxial rig specially modified to

carry out high speed monotonic tests. The rig is capable of axial

displacement rates of 100 mm/s, and during high speed testing it

is controlled by a GDS digital system capable of controlling the

axial displacement within a time interval of 0.1 milliseconds.

Both the back and cell pressures were provided by GDS

pressure controllers. Lubricated end platens of a similar design

to those proposed by Rowe and Barden (1964) were used in

order to minimise the inhomogeneity caused by end restraint

conditions. As these can introduce errors into the measurement

of small strains using external methods, these were measured

using Hall effect transducers, two axial and one radial, mounted

directly on the sample providing a resolution of 1×10

-6

% strain.

Pore pressures were monitored using a mid-height pore pressure

transducer mounted on the surface of the sample.

2.2

Testing programme

The testing programme consisted of triaxial tests at shear strain

rates from 0.333 to 60,000 %/hr in order to investigate strain

rate effects over as large a range as possible. These were carried

out at a comparatively low effective stress of 300 kPa as

previous studies have shown that greater rate effects are

observed at higher moisture contents. (Bea 1982, Brown and

Hyde 2008, Chow and Airey 2011) Throughout the testing

programme, the samples were allowed to drain through the filter

paper drains in order to allow rate effects due to consolidation

to be investigated.

3 RESULTS AND DISCUSSION

3.1

Observed rate effects and their modelling

The rate effects observed at the various strain rates are shown in

Figure 2, with a shear strain rate of 100 %/hr taken as the

reference rate. In order to allow comparison with other studies

using differing materials and sample sizes, the strain rates have

been converted into the normalised dimensionless velocities

used by Randolph and Hope (2004) as shown in Equation 1.

v

c

vd V

(1)

where

V

is the normalised dimensionless velocity,

v

is the

strain rate applied (in m/year),

d

is the sample diameter (in m)

and

c

v

is the co-efficient of consolidation in m

2

/year. As can be

seen, the curve follows the behaviour expected with time for

consolidation effects dominating up to

V

= 11, after which

undrained viscous effects are significant.

In order to quantitatively assess the data, the rate effects

model proposed by Randolph and Hope (2004) shown in

Equation 2 has been fitted to the data using least mean square

regression.

0

ref

1

0

1

d

ref

V

V

sinh

V

V sinh

)10(ln

λ

1

cV 1

b 1

q

q

(2)

where

b

,

c

, and

d

are curve fitting parameters used to model

the time for consolidation effects and

λ

is the rate effect per log

cycle increase in strain rate used to model viscous effects.

V

ref

is

the normalised velocity associated with chosen reference rate

and

V

0

is the point after which time for consolidation effects are

negligible. This process was also repeated for the measured rate

effects at selected strains to identify the variation in rate effects

at different strain levels as shown in Figure 3. The parameters

obtained from the curve fitting process are shown in Table 2.

The fitting parameters at peak strength (which occurs at

varying strain levels) show that the rate effect per log cycle was

found to be 22.5% which is higher than previous studies. This

highlights the need to develop a framework to predict rate

effects based on the current soil state and properties of the

material in question.