269

Technical Committee 101 - Session I /

Comité technique 101 - Session I

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

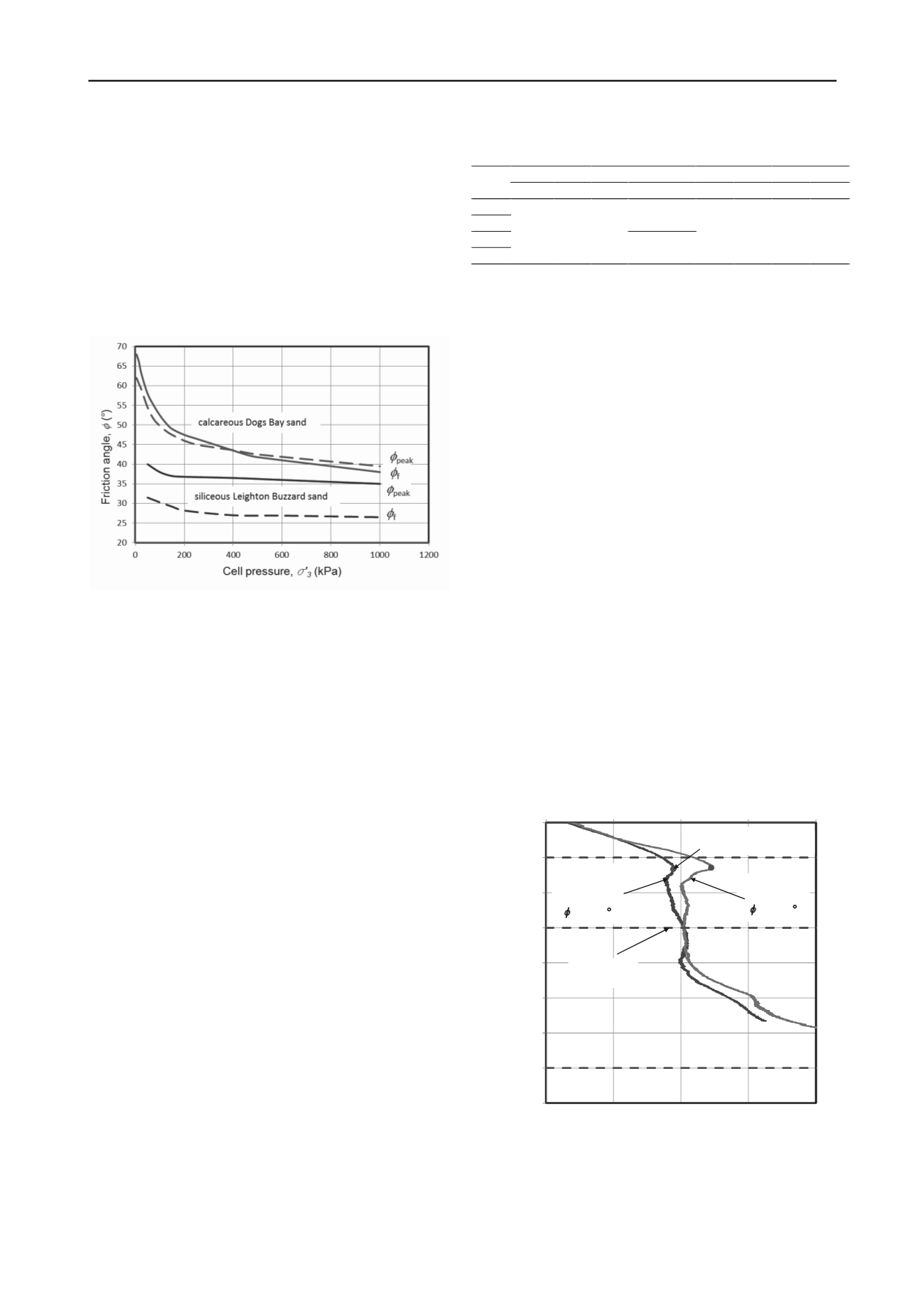

A similar tendency can be found from the experimental

results reported by Desrosiers and Silva (2002). A direct

comparison was made between the behaviour of carbonate sand

from South Australia and silica sand from the United Kingdom.

At steady state shearing, the carbonate sand was already in

contraction under 500 kPa confining stress, while the silica sand

was still in dilation under 1000 kPa. The early transition to

contractive behaviour attributes the fact of particle degradation

of carbonate sand. The low grain hardness caused the grain to

start crushing at relatively low stresses and hindered the

development of potential maximum dilation. This behaviour

agrees well with that observed on the NWS carbonate sand.

Figure 3. Comparison of dilative behaviour between calcareous and

siliceous sand under various cell pressures (Golightly and Hyde 1988).

4 PRACTICAL APPLICATION: SPUDCAN RESPONSE

In order to examine the influence of this disparate characteristic

of carbonate and silica sands on practical applications, model

tests were carried out on spudcan foundations penetrating

through four-layer soils, with a carbonate or silica sand layer

interbedded in soft clay. The experimental program was carried

out at 200 g in a drum centrifuge. The soil was confined within

a purpose designed strongbox to facilitate producing multi-layer

specimens, with the box mounted within the drum channel

(Hossain and Randolph 2012).

Spudcan penetration tests were performed using a half-

spudcan (HS) and a full-spudcan (FS) model of 60 mm (12 m

prototype) diameter. The models were made from duraluminium

and included a 13

shallow conical underside profile (included

angle of 154

) and a 76

protruding spigot. The half-spudcan

was designed to penetrate adjacent to the strongbox window,

permitting the soil deformation to be captured by a camera.

Separate full-spudcan penetration tests were performed away

from the edges of the box to measure the load-penetration

response, avoiding frictional resistance from the window.

Table 2 provides a summary of all centrifuge tests reported.

Four tests encompassed two different four-layer profiles: (i) soft

clay-carbonate sand-soft clay-stiff clay; (ii) soft clay-silica

sand-soft clay-stiff clay. These multi-layer clay samples were

prepared off the centrifuge. Two samples of uniform strength

were prepared by consolidating thoroughly mixed, and then de-

aired, kaolin slurry at 1 g in separate cells. Two different final

pressures were used to obtain comparatively strong and soft

samples. Each clay layer, as detailed in Table 2, was then cut to

size of the strongbox. The bottom two (3

rd

and 4

th

) clay layers

were amassed in the strongbox. A layer of water was poured

into the strongbox. Dry super fine silica sand (or carbonate

sand) was then air-pluviated into the strongbox on top of the

placed lower layers. A loose to medium dense layer was

deposited by raining the sand maintaining a relatively small

sand drop height of about 100 mm. The sand surface was

carefully levelled and the top clay layer was placed.

Table 2. Summary of centrifuge tests reported (

D

= 12 m).

Layer 1

Layer 2

Layer 3

Layer 4

Test

t

1

/

D

Soil

t

2

/

D

Soil

t

3

/

D

Soil

t

4

/

D

Soil

FS1

HS1

Carbonate

sand

FS2

HS2

0.25 Soft

clay 0.5

Silica

sand

0.96 Soft

clay 0.33 Stiff

clay

Commercially available kaolin clay and super fine silica

sand are commonly used for centrifuge model tests at UWA and

an abundance of reliable data exists regarding the geotechnical

properties (e.g. Stewart 1992, Cheong 2002). The carbonate

sand was dredged directly from the North-West Shelf of

Australia, as discussed previously. The critical state friction

angles of the silica and carbonate sands were 34

and 40

,

respectively.

The densities of the sand layers, which were determined by

measuring the total added sand weight and the volume formed

for all cases, corresponded to an average relative density,

I

D

, of

44%. For the clay beds, characterisation tests were carried out

using a T-bar penetrometer, of diameter 5 mm and length

20 mm (model scale).

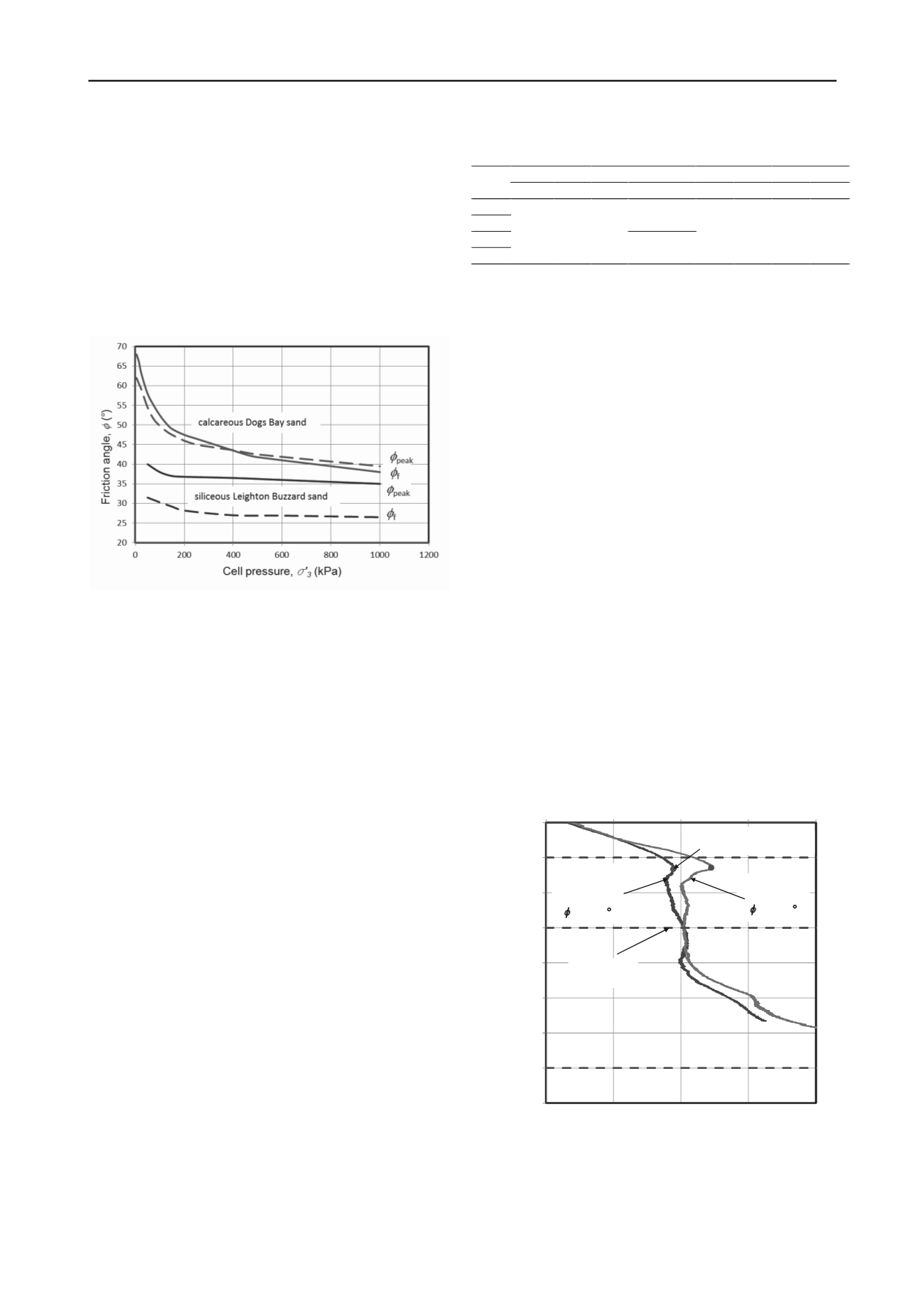

Figures 4 and 5 show the results from full-spudcan and half-

spudcan tests, respectively. The load-penetration responses (see

Figure 4) are presented in terms of ultimate bearing pressure,

q

u

=

P

/

A

(where

P

is the penetration resistance and

A

is the largest

plan area of the spudcan), as a function of normalised

penetration depth,

d

/

D

. The potential for punch-through failure,

with a local maximum in penetration resistance followed by

some reduction, occurred for all cases investigated. The severity

of failure is conventionally quantified by (a) the degree of post-

peak reduction in resistance and (b) the ‘additional penetration’

before the peak resistance is re-established. By comparing the

penetration resistance profiles for Test FS1 and Test FS2, on

identical soil profiles with identical sand relative density, the

measures of punch-through severity were significantly higher

for the sandwiched silica sand despite its lower friction angle

(

crit

= 34

compared to 40

). This is due to the behaviour of

carbonate sand, as discussed previously and also described

below.

0

0.25

0.5

0.75

1

1.25

1.5

1.75

2

0

100

200

300

400

Normalised penetration depth,

d

/

D

Vertical bearing pressure,

q

u

(kPa)

Soft clay

Soft clay

Carbonate

sand

I

D

= 38%;

crit

= 40

Silica sand

I

D

= 38%;

crit

= 34

Stiff clay

Punch-

through

Layer

interface

Figure 4. Effect of interbedded sand mineralogy on load penetration

response: severity of punch-through (Tests FS1 and FS2, Table 2).

The accompanying soil deformation patterns are shown in

Figure 5 by means of contours of the incremental absolute soil

flow velocity

v

normalised by the foundation speed

v

spud

. The

ratio

v

/

v

spud

of unity indicates that the soil moves with a speed