278

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

particles that are initially hidden in larger shells come loose

after manipulation.

Figure 6a and 6b. S2-sand after wetting and drying in the oven.

Even though crushing is most often evaluated through

granulometric distribution of equivalent grain diameters,

microscopic analysis of the sand grains is a useful addition to

fully quantify the effects of crushing as well as less invasive

abrasion and polishing. Microscopy allows for exact

measurement of grain dimensions, as opposed to a system of

sieves that is based on the assumption that particles are perfectly

spherical.

On a sample scale, Scanning Electron Microscopy might be a

useful tool for viewing the sand matrix and the intergranular

contacts, thus offering more insight in the effective stresses.

4 DEDUCTION OF SOIL MECHANICAL PROPERTIES

Findings from the laboratory tests must finally be translated to

geotechnical situations with crushable sand. On site conditions

are generally different from the laboratory: The very angular

shape of the grains causes an anisotropic behaviour; water and

temperature environment will be different; there is the scale

effect of the small-scale samples; ageing can cause cementation

that is hard to simulate in the lab. Crushing is a time effect and

therefore has more time to establish in the field than in the lab.

Corresponding to a continuous creep with time, the behaviour of

crushable sands also depends on the strain rate (Nutt and

Houlsby 1991), i.e. the possibility to form new structures

without crushing.

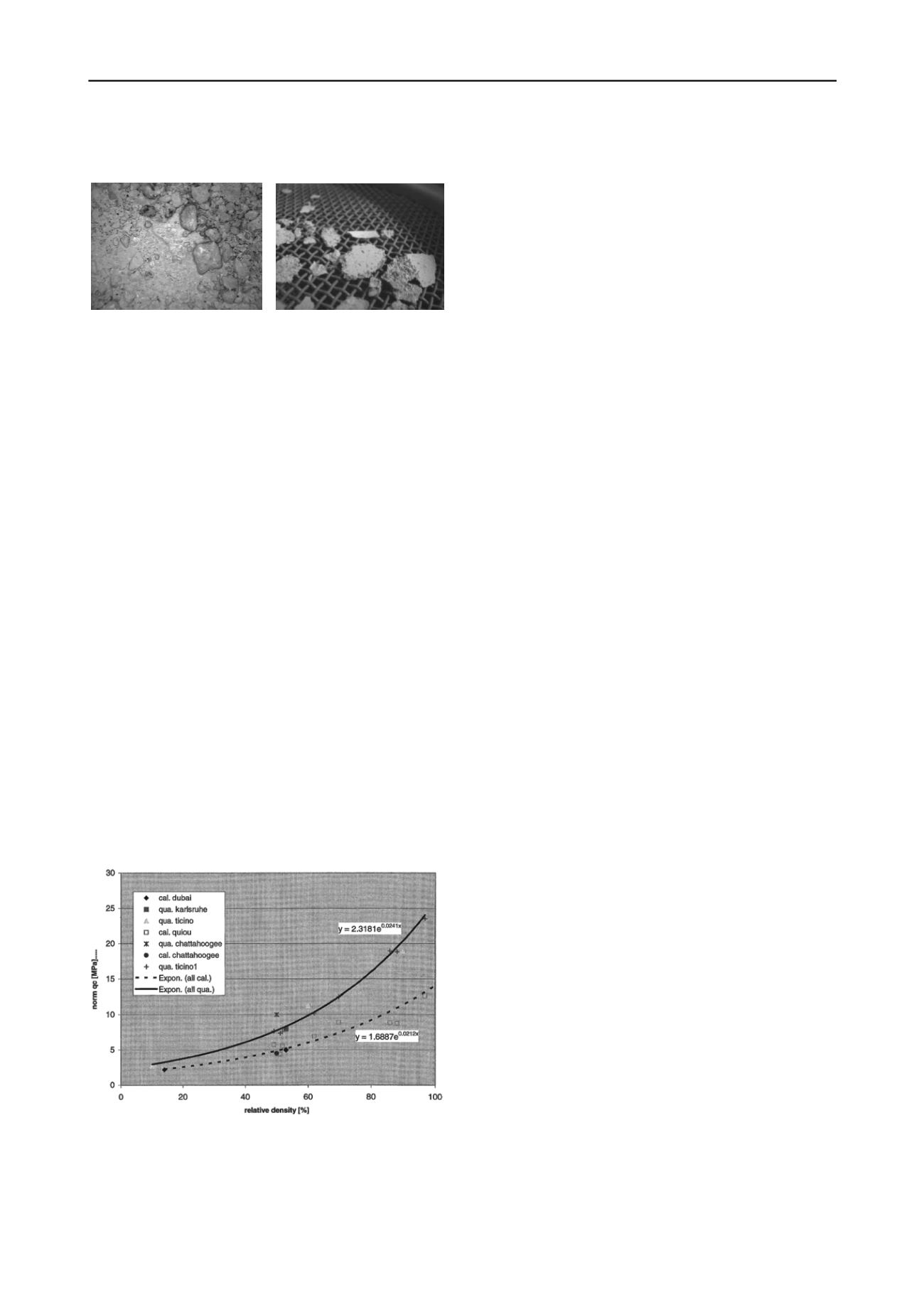

Correlations between geotechnical parameters that are based on

in situ experience with non-crushable sands, omit the specific

behaviour of crushable materials. As a solution, Wehr (2005)

links the differing best-fits between cone resistance and relative

density for silica and calcareous sand, through a “shell

correction factor” – without however revising the entire

correlation.

Figure 7. The correlations between relative density and cone resistance

for quartz and calcareous sands can be related through a “shell

correction factor” that depends on the relative density (Wehr 2005).

5 CONCLUSIONS

Just as research on sand differs from research on clay, crushable

sands also need a different approach from non-crushable,

cohesionless sands. Sample preparation, test procedure and

interpretation need revising to accommodate for the crushability

and the angularity of the grains. The phenomenon of crushing,

which causes the sand-grains and sand-structure to alter

significantly during a test, complicates testing and the used sand

should be closely monitored throughout.

Usage of a crushable sand causes grain degradation, which

manifests as erosion or breakage, anyhow altering the minimum

and maximum density of the sand. Consequently, unlike silica

sands, geotechnical parameters of crushable sands cannot be

derived through correlations with the calculated “relative

density”, which is sensitive to errors in the limit density

determinations and which has no real meaning for crushable

sand. By the same token, crushing cannot be evaluated through

sieving alone, a closer look at the grain morphology by means

of microscopy is required to fully understand the structure and

thus, the behaviour of crushable sands.

6 ACKNOWLEDGEMENTS

The authors acknowledge the Belgian Dredging company

DEME, for providing the sands used in this study.

7 REFERENCES

ASTM Standard D4254, 2000, “Standard Test Methods for Minimum

Index Density and Unit Weight of Soils and Calculation of Relative

Density,” ASTM International, West Conshohocken, PA, 2006,

DOI: 10.1520/D4254-00,

.

ASTM Standard D425, 2000 (2006), “Standard Test Methods for

Maximum Index Density and Unit Weight of Soils Using a

Vibratory Table,” ASTM International, West Conshohocken, PA,

2006, DOI: 10.1520/D4253-00R06,

.

ASTM Standard D2435, 1996, “Standard Test Methods for One-

Dimensional Consolidation Properties of Soils,” ASTM

International, West Conshohocken, PA, DOI: 10.1520/D2435-96,

.

ASTM Standard D422, 1963 (1998), “Standard Test Method for

Particle-Size Analysis of Soils,” ASTM International, West

Conshohocken, PA, DOI: 10.1520/D0422-63R98,

.

Hardin B.O. 1985, Crushing of Soil Particles,

Journal of Geotechical

Engineering

, ASCE, 111(10), 1177-1192.

JIS A 1224 Standard, 1992 (2009), Test Method for Minimum and

Maximum Densities of Sands, Japanese Geotechnical Society,

(in Japanese).

Ladd R.S. 1978. Preparing Test Specimens Using Undercompaction,

Geotechnical Testing Journal

, ASCE, 1(1), 16-23.

Nutt N.R.F. 1993, Development of the Cone Pressuremeter, DPhil,

University of Oxford.

Nutt N.R.F., Houlsby G.T. 1991, Calibration Tests on the Cone

Pressuremeter in Carbonate Sand,

Proceedings of the First

International Conference on Calibration Testing

, Potsdam, New

York, 265-276.

Semple R.M. 1988. The mechanical properties of carbonate soils

.

Proceedings of the International Conference on Calcareous

Sediments

, Perth, Australia, Vol. 2, 397-406.

Wehr J. 2005. Influence of the Carbonate Content of Sand on Vibro

Compaction,

Proceedings of the 6th International Conference on

Ground Improvement Techniques

, Coimbra, Portugal, 625-632.

Youd T.L. 1973. Factors Controlling Maximum and Minimum

Densities of Sands,

Evaluation of Relative Density and Its Role in

Geotechnical Projects Involving Cohesionless Soils

, ASTM STP

523, American Society for Testing and Materials, 98-112.