286

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

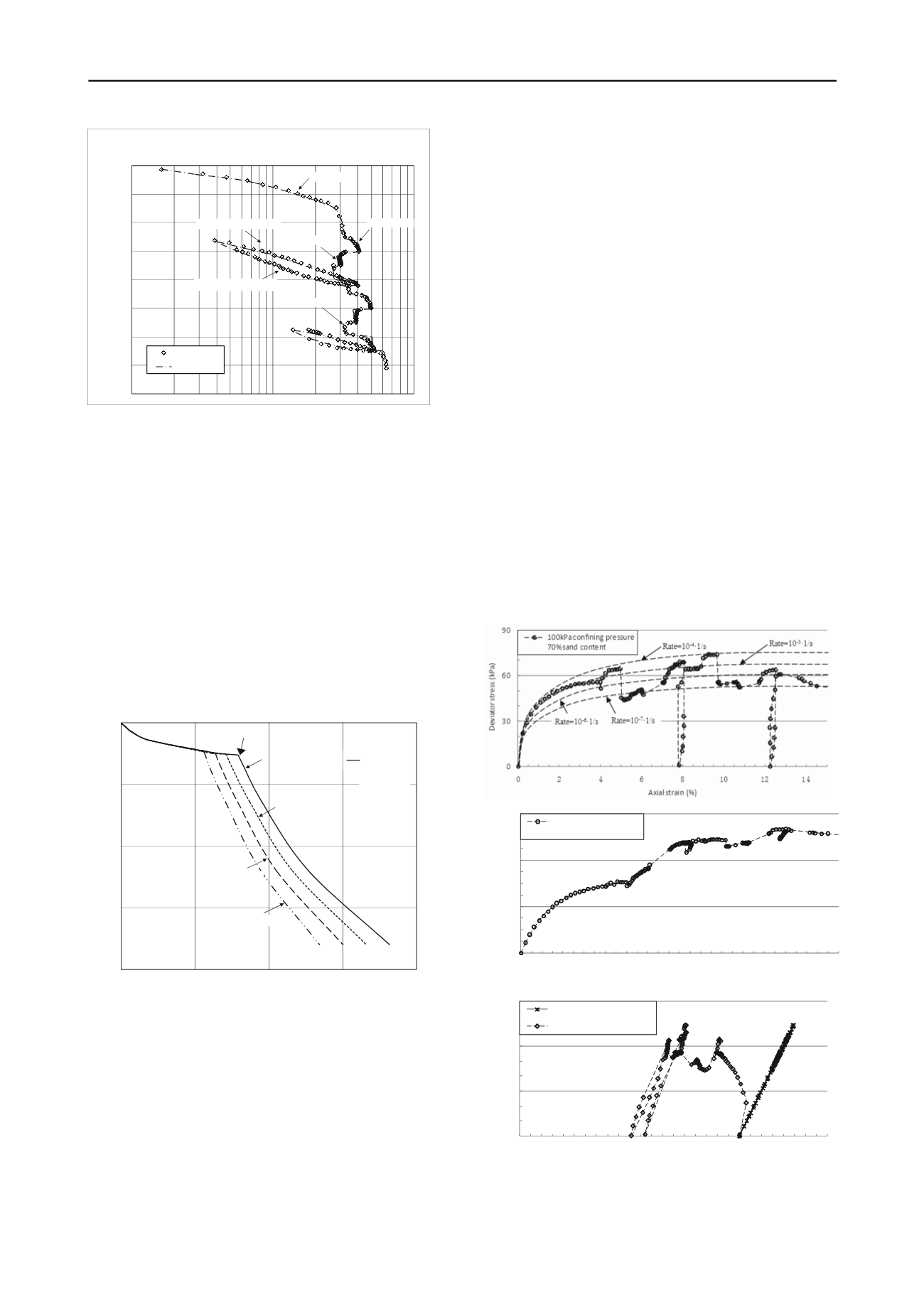

4. CONSOLIDATED UNDRAINED TRIAXICAL

CONPRESSION TESTS ON BENTONITE MIXED

WITH SAND AND RESULTS

The authors have done consoldated undrained triaixal tests on

the same bentonite mixted with different ratios of silicon sand

with effective confining pressure of 50 kPa, 100 kPa and

200 kPa. Curves of (a) deviator stress versus axial strain, (b) the

excess porewater pressure versus axial strain, and (c) the

deviator stress versus effective (or total) mean stress of a CU

test on bentonite mixed with 70% of sand and effective cell

pressure of 100 kPa are shown in Figure 6. It is seen from

Figure 6 that the effects of strain rates are very significant. The

unloading-reloading loops are also evident.

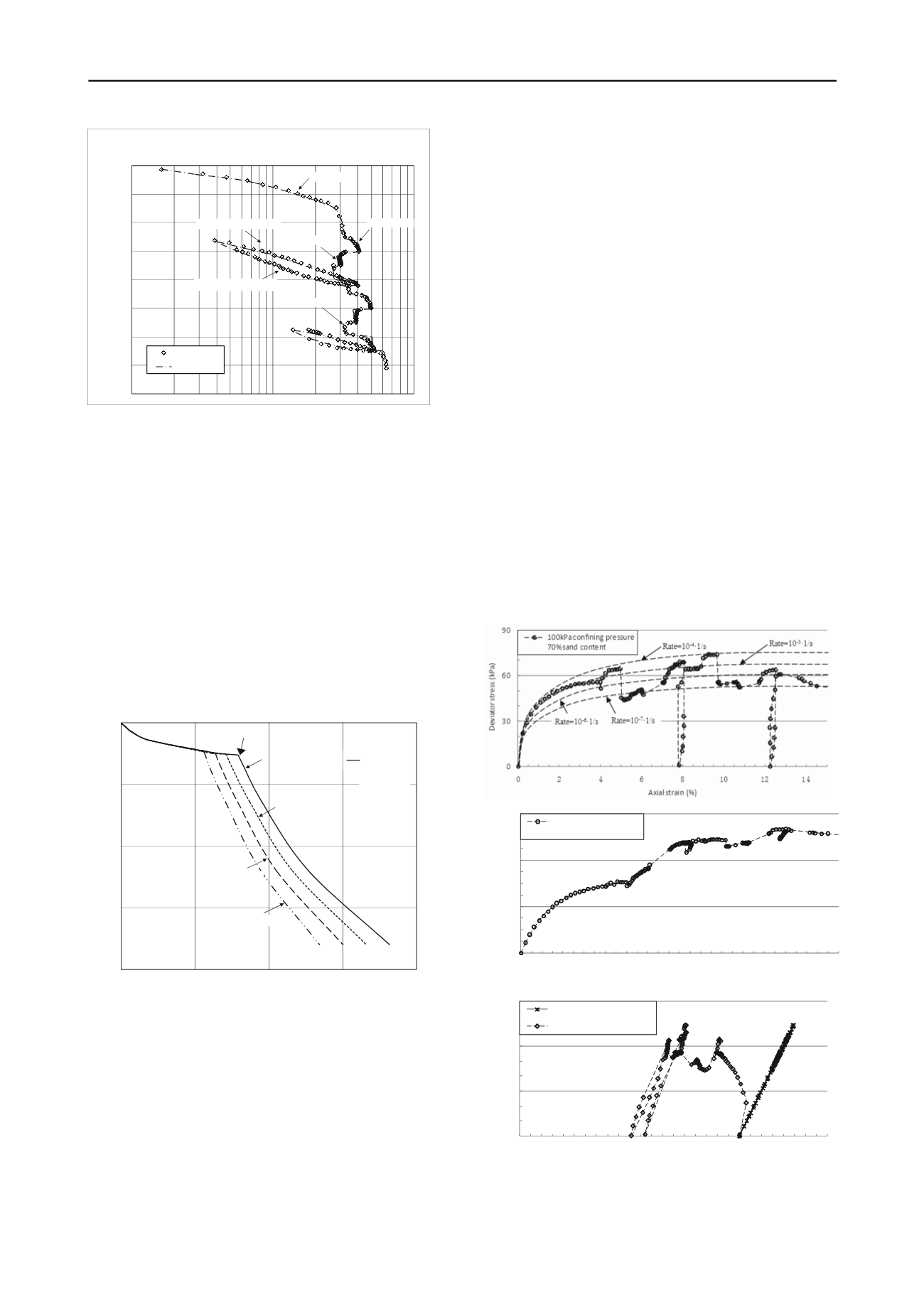

Figure 5. Simulation for strain rate dependent stress-strain behavior in

CSR tests using the EVPS model

5. CONCLUSIONS

From the above presentation and study, the following

conclusions can be drawn:

(a) The stress-strain behavior of a bentonite mixed with

different percentages of silicon sand exhibits strong

dependence on time and strain rate.

(b) Creep, swelling, relaxation and strain effects are clearly

observed and are significant.

(c) In 1D straining condition, there exists a creep region with

stress-strain state closer to the normal consolidaition line

(NCL) and a swelling region far awar from the NCL.

(d) The 1D EVPS model can re-produce well the time-

dependent stress-strain behavior of the soil including creep,

swelling, strain effects, relaxation, and unloading-reloading

loops in 1D straining condition.

0

2

4

6

8

10

12

14

16

1

10

100

VerticalStrain, ε

z

(%)

Vertical effectivestress (log scale), σ’

z

(kPa)

(e) The data from 2D consolidated undrained triaxial

compression tests on the bentonite-sand mixure also show

the strain effects and unloading-reloading loops.

6. ACKNOWLEDGEMENTS

Financial supports (G-U663 and G-YG60) by The Hong Kong

Polytechnic University are acknowledged.

7. REFERENCES

Yin, J.-H. and Graham, J. 1989. Visco-elastic-plastic modeling of one-

dimensional time-dependent behaviour of clays. Canadian

Geotechnical Journal, 26(3), 199-209.

Yin, J.-H. and Graham, J. 1994. Equivalent times and one-dimensional

elastic visco-plastic modeling of time-dependent stress-strain

behavior of clays. Canadian Geotechnical Journal, 31(2), 42-52.

Yin, J.-H. and Graham, J. 1999. “Elastic visco-plastic modelling of the

time-dependent stress-strain behavior of soils”. Canadian

Geotechnical Journal, 36(4), 736-745.

Yin, J.-H. and Tong, F. 2011. Constitutive modeling of the time-

dependent stress-strain behaviour of saturated soils exhibiting both

creep and swelling. Canadian Geot. J.l, 48(12), 1870-1885.Gibson

R.E. and Henkel D.J. 1954. Influence of duration of tests at

constant rate of strain on measured “drained” strength.

Géotechnique

4 (1), 6-15.

Tong, F and Yin, JH (2011). "Nonlinear Creep and Swelling Behavior

of Bentonite Mixed with Different Sand Contents under

Oedometric Condition". In the Journal of Marine Georesources

and Geotechnology, Volume 29

,

346~363.

0

5

10

15

20

0

20

40

60

8

Vertical Strain, ε

z

(%)

Vertical effectivestress, σ’

z

(kPa)

0

EVPS Modeling

=10

-5

1/sec

=10

-4

1/sec

=10

-6

1/sec

=10

-7

1/sec

ψ

c

/V=0.00801

ψ

s

/V=0.00704

The preconsolidation pressure increases with strain

0

20

40

60

0

2

4

6

8

10

12

14

Excess porewater pressure (kPa)

Axialstrain (%)

100kPaconfining pressure

70%sand content

0

30

60

90

0

20

40

60

80

100

120

140

Deviatorstress (kPa)

Meanstress (kPa)

TSP 100kPaconfining pressure

ESP 100kPaconfining pressure

Figure 6. (a) Deviator stress

versus

axial strain, (b) the excess

porewater pressure

versus

axial strain, and (c) the deviator stress

versus

effective (or total) mean stress – CU test on bentonite mixed with 70%

of sand and effective cell pressure of 100 kPa

(c)

(a)

(b)

CRS

EVPS Modeling

Rate=10

-5

1/sec

Rate=10

-4

1/sec

Rate=10

-6

1/sec

Rate=10

-7

1/sec

UnloadingRate=10

-5

1/sec

ReloadingRate=10

-5

1/sec

Figure 4. Comparison of modelling results with measured data from

a CRS test with step-changed strain rates and with unloading and

reloading