281

Technical Committee 101 - Session I /

Comité technique 101 - Session I

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

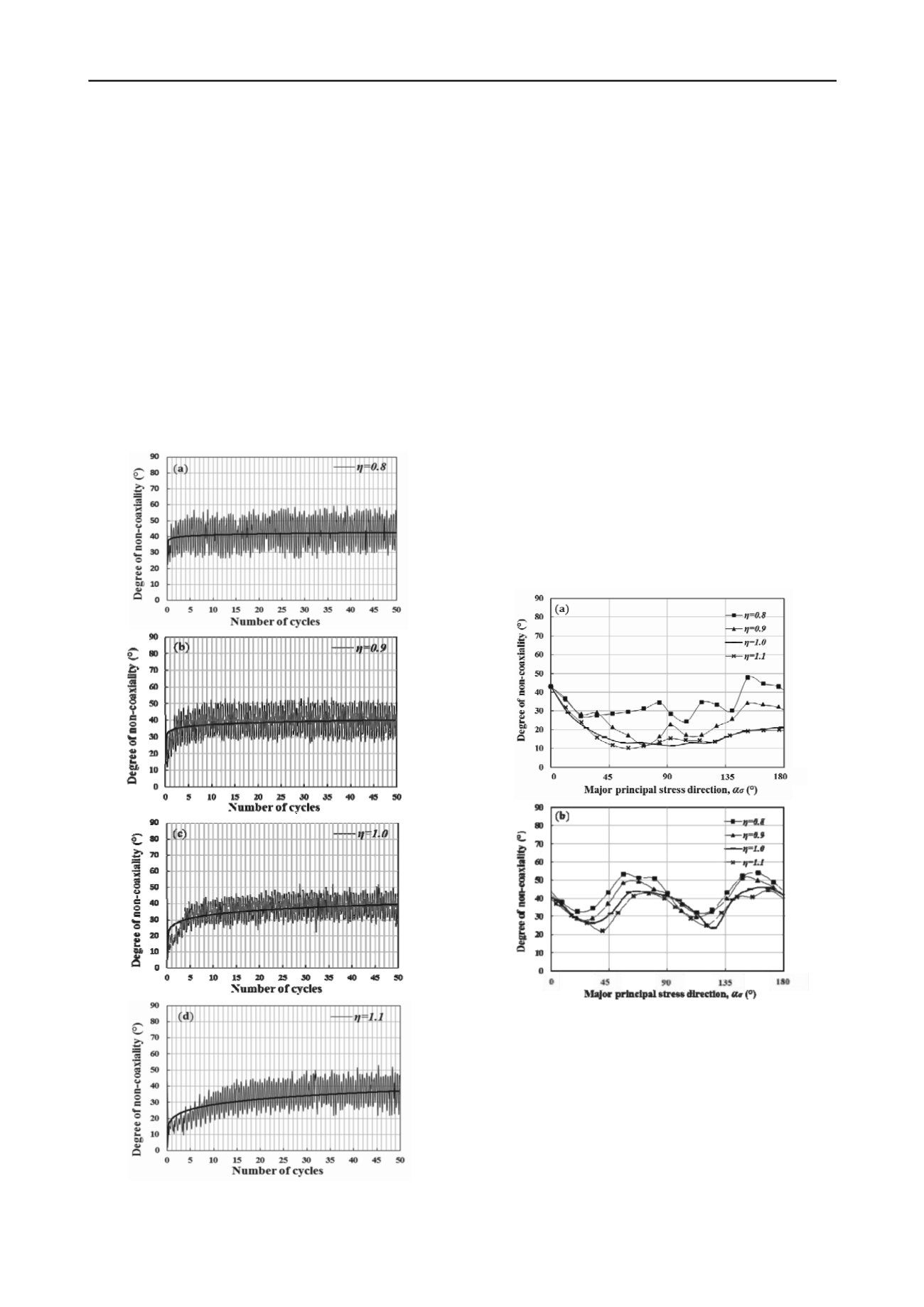

oaxiality as measured by the deviation

cipal stress direction and the principal

3.2

Non-coaxiality

The degree of non-c

between the major prin

strain increment direction, (

α

d

ε

-

α

σ

) for tests with different stress

ratios are plotted in Figure 4(a) - (d). As elastic strain increment

takes a much smaller proportion in the total strain increment

compared to that of the plastic strain increment (Gutierrez et al.

1991), the total strain increment instead of the plastic strain

increment is used in the following analysis. In general, the

variation trend of the non-coaxiality degree shows an obvious

oscillation during the tests. Lower degrees of non-coaxiality are

observed in the first few cycles. When the rotational shear

continues, the strain increment direction becomes closer to the

stress increment direction and higher degrees of non-coaxiality

are observed. After about 20 rotation cycles, the variation of the

non-coaxiality degree appeared to be stabilized. It is clear that

the increasing trend of the non-coaxiality degree at the initial

stage is more obvious for tests with higher stress ratios.

Figure 4. Degree of non-coaxiality against number of cycles for test

with: (a)

η

=0.8; (b)

η

=0.9; (c)

η

=1.0; (d)

η

=1.1.

atio (

η

=0.8), (

α

dε

-

α

σ

)

The black solid lines in Figure 4 are the trend lines of the

non-coaxiality degree. With a lower stress r

is closer to 45°, indicating the strain increment direction is

closer to the stress increment direction. At the same number of

cycles, the degree of non-coaxiality decreased with the increase

of the stress ratio. This observation agrees well with the

laboratory results presented by Gutierrez et al. (1991) and

numerical results obtained by Li and Yu (2009) based on DEM

simulations.

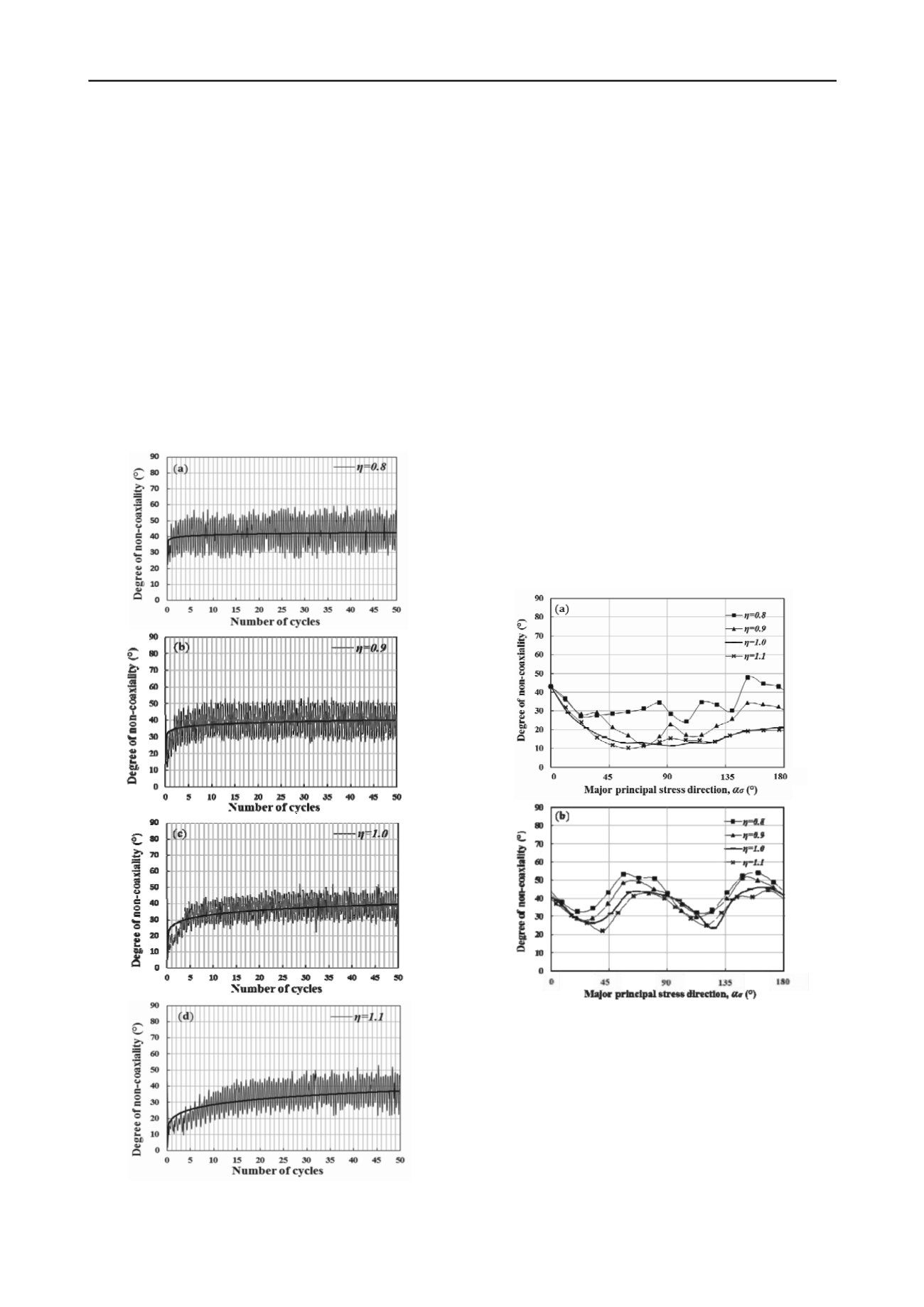

As described above, the variation trend of the non-coaxiality

degree shows an obvious periodicity during the tests. To have a

better view, the relationship of the non-coaxiality degree with

the major principal stress direction

α

σ

at the cycle numbers

N

=1

and

N

=20 are presented in Figure 5(a) and 5(b). Figure 6 shows

the corresponding stress paths and strain increments in these

tests. It is clear that the variation of the non-coaxiality degree

differs significantly at the two stages. At the initial stage when

N

=1 the degree of non-coaxiality lies approximately in the

range of 10 to 40°, as shown in Figure 5(a). It tends to decrease

when

α

σ

rotates from 0 to 90° and then increase during the latter

half cycle’s rotation. However, at

N

=20 (Figure 5b), the

fluctuation of the non-coaxial degree exhibits two periods of a

sine wave displaced at 180 degree intervals. Meanwhile, as

mentioned above, the stress ratio has a significant effect on the

non-coaxiality degree. The larger the stress ratio, the lower non-

coaxial degree between the directions of the strain increment

and stress is induced.

Figure 5. Degree of non-coaxiality for rotational shear tests at: (a)

N

=1;

and (b)

N

=20.

crements are gradually enlarged with the increase

As shown in Figure 6, for both

N

=1 and

N

=20, the directions

f the strain in

o

of the stress ratio. It is interesting to see that for

N

=20 the strain

increment differs significantly in different sections. When the

principal stress axes rotate along the stress paths of DA and BC,

which correspond to the major principal stress direction

α

σ

in

ranges of [45°, 90°] and [135°, 180°], the strain increment

direction almost coincides with the stress increment direction.

Similar results have been reported by Tong et al. (2010). For

lower stress ratios such as

η

=0.8 and 0.9 in Figure 6, several

arrows pointed inside the cycle, indicating the strain increment