284

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

staged isotropic loading tests with unloading/reloading and with

creep and swelling, and (ii) step-changed constant rate of strain

consolidated undrained compression tests (CU tests) in triaxial

state. From these test data, creep, swelling, relaxation, and strain

rate effects are investigated and discussed.

Based on the 1D Elastic Visco-Plastic (1D EVP) models

developed by Yin and Graham (1989, 1994, 1999), the authors

have proposed a new 1D Elastic Visco-Plastic model

considering both creep and swelling (called 1D EVPS) (Yin and

Tong 2011). The data from the multi-staged oedometer tests are

used to calibrate the new 1D EVPS model. After this, 1D EVPS

model is used to simulate the step-changed constant rate of

strain compression tests in 1D straining and other types of tests

and make comparisons.

Unloading-reloading loop due to swelling-creep

Normal c

line (NCL)

onsolidation

2. OEDOMETER TESTS ON BENTONITE MIXED WITH

DIFFERENT SAND CONTENTS AND RESULTS

The authors have done a series of oedometer tests on a mixture

of bentone and silicon sand with silicon sand contents of 50%,

60%, 70%, 80% and 90%. Table 1 gives a simmay of basis

properties of the mixtue with 60%, 70%, and 80% (Tong and

Yin 2011).

Table 1 Basic properties for different bentonite-sand mixed samples

Sand proportion

50%

60%

70%

Water Content (%)

211.5

159.0

124.5

Liquid Limit W

L

(%)

146.0

106.0

82.6

Plastic Limit W

P

(%)

29.9

28.7

27.4

Plastic Index I

P

(%)

121.1

77.3

55.2

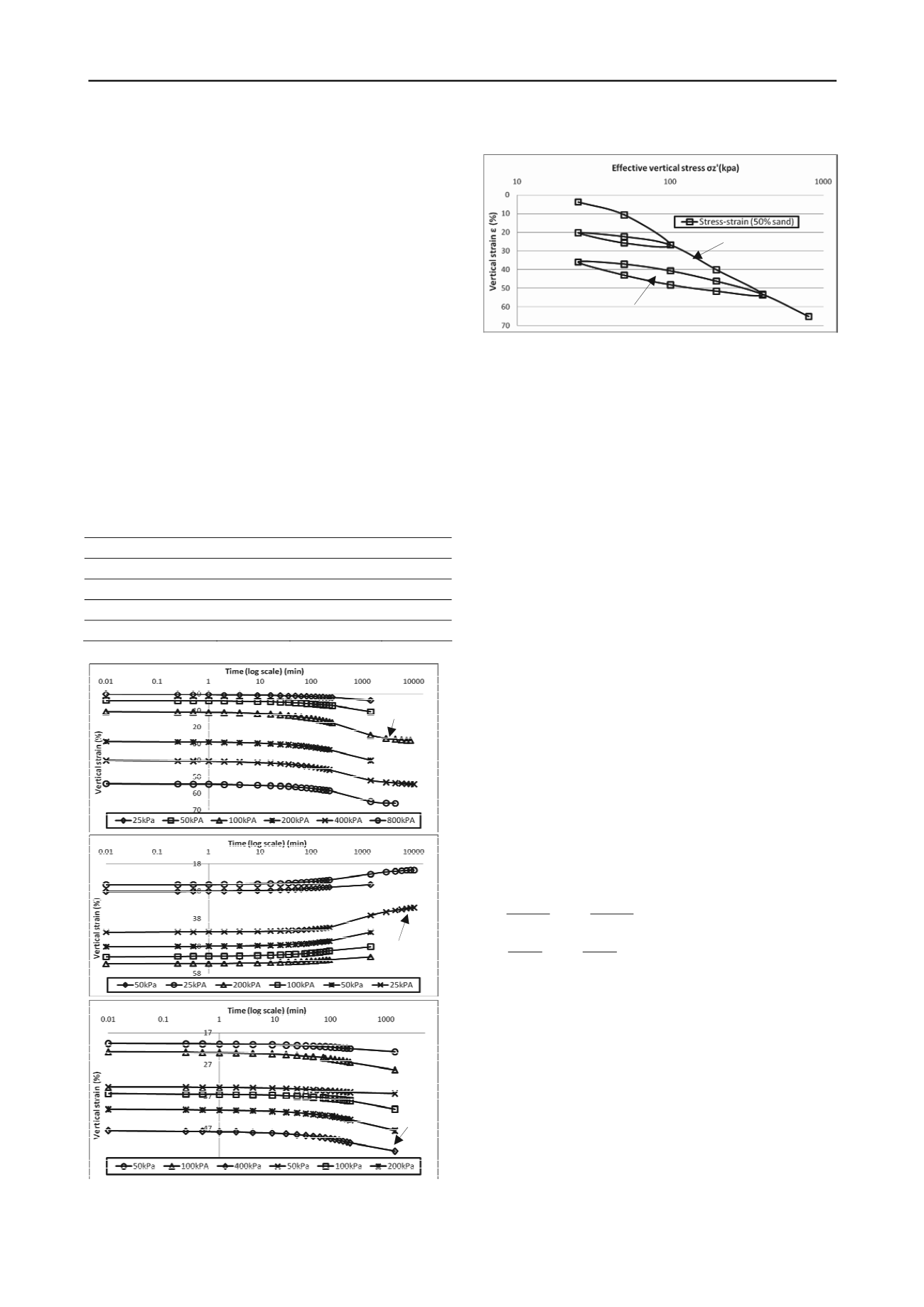

Figure 1. Vertical strain against time in log scale for 50% sand mixed

with 50% bentonite (a) loading, (b) unloading, and (c) reloading

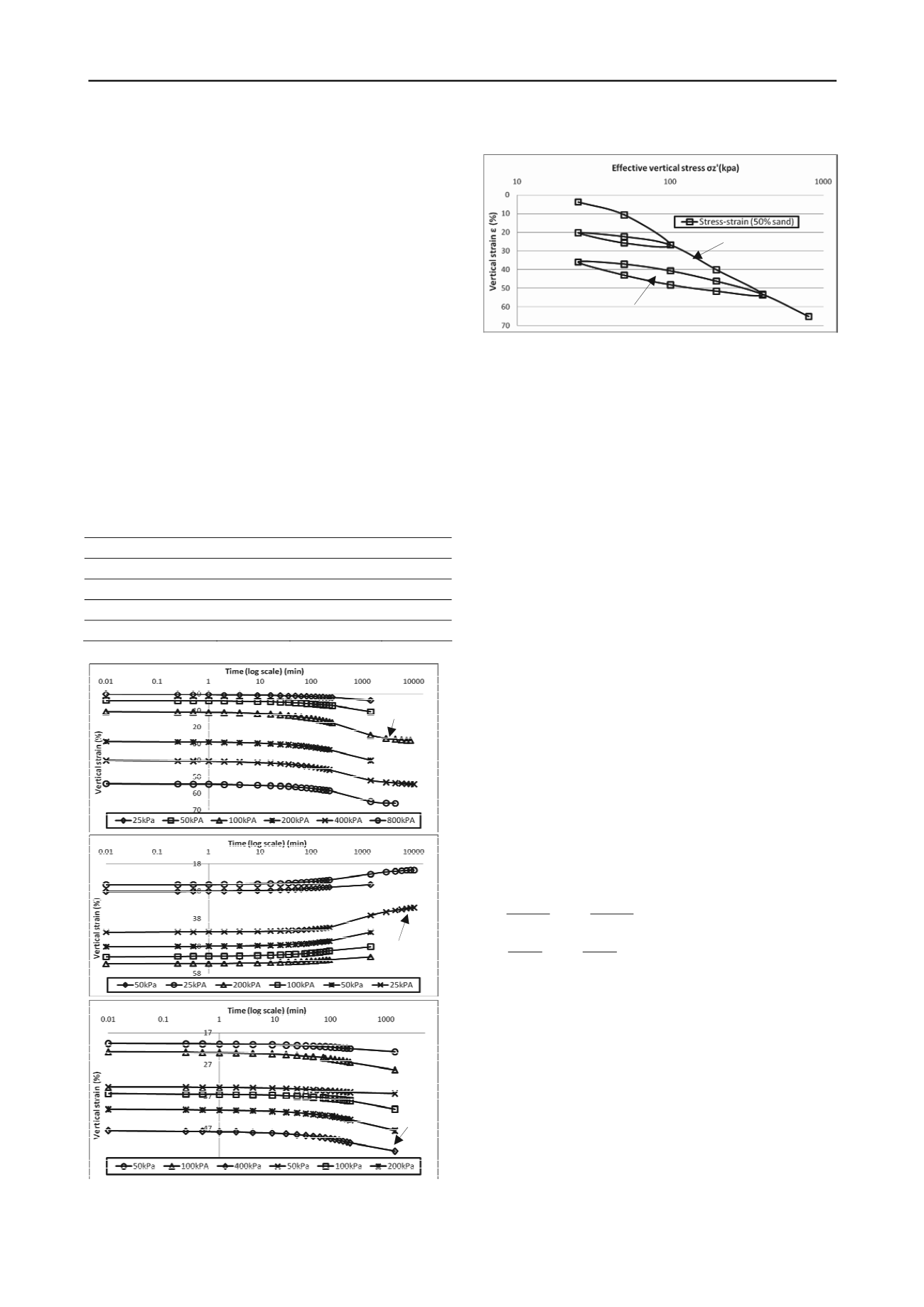

Figure 2. Vertical strain against vertical effective stress in log scale

from tests on bentonite-sand mixture (50% sand content)

The curves of log(time) and vertical strains for a mixture of

50% bentone and 50% sand are shown in Figure 1. The

oedometer test was carried out in stages and with unloading-

reloading.

It is clearly seen from Figure 1(a) and (b) that the mixture

exhibits both time-dependent creep and swelling. It is noted

that “swelling” here is neither the rebound due to unlading, or

the expansion of an unsaturated clay due to absorbing water.

Instead, the “swelling” here is defined expansion of a saturated

clay due to swelling potnetial of the clay udner a constant

vertical effective stress. The “swelling” here is oposite to teh

creep.

Figure 2 shows the curve of vertical strain against vertical

effective stress in log scale from tests on bentonite-sand mixture

(50% sand content) with duration of 24 hours for each loading.

It is seen from the figure that there are two unloading-reloading

loops. The authors belive that the swelling and creep contribute

to the loops. This is because that when the specimen is

unloaded to very stress-strain state far from the normal

consolidaiton line (NCL), the swelling poential of the mixture

has caused the clay to expand and caused the time-depepdeint

reduction of strain. When the specimen is re-loaded to the

stress-strain state closer to the NCL, the mixtuer will have creep

compression. The authors also consider that the partical

movements of the mixture may also contribute to the formation

of the loops.

It is noted that the curves of log(time) and vertical strains

and the curves of vertical strain against vertical effective stress

in log scale of other mixtures are similar to those in Figures 1

and 2. From all test data, the authors have detrmined values of

compression index

C

c

, rebound index

C

r

, creep coefficient

C

�

and swelling coefficient

C

s

. The definitions of those parameters

are:

(1)

Values of

C

c

,

C

r

,

C

�

and

C

s

are presented in Table 1. In Table 1,

the ratio of

c

and

r

s

are also given. The following

ovservations can be obtained grom Table 2:

CC

/

CC

/

Both the compression index

C

c

and recound index

C

r

decrease with the increase of the sand content. This means

that the more the sand content, the less compresssion of the

mixture.

In generally speaking, the creep coefficient

C

�

decreases with

the increase of the sand content. This means that the more the

sand content, the less creep of the mixture. In addition, the

coefficient

C

�

also decreases with the increase of the vertical

effective stress.

In generally speaking, the swelling coefficient

C

s

decreases

with the increase of the sand content. This means that the

more the sand content, the less swelling of the mixture. In

addition, the coefficient

C

s

increases with the decrease of the

vertical effective stress.

(b)

(c)

(a)

Creep

Swelling

Creep

t

e

C

t

e

C

e

C e

C

s

z

r

z

c

log

;

log

log

;

log

'

'