280

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

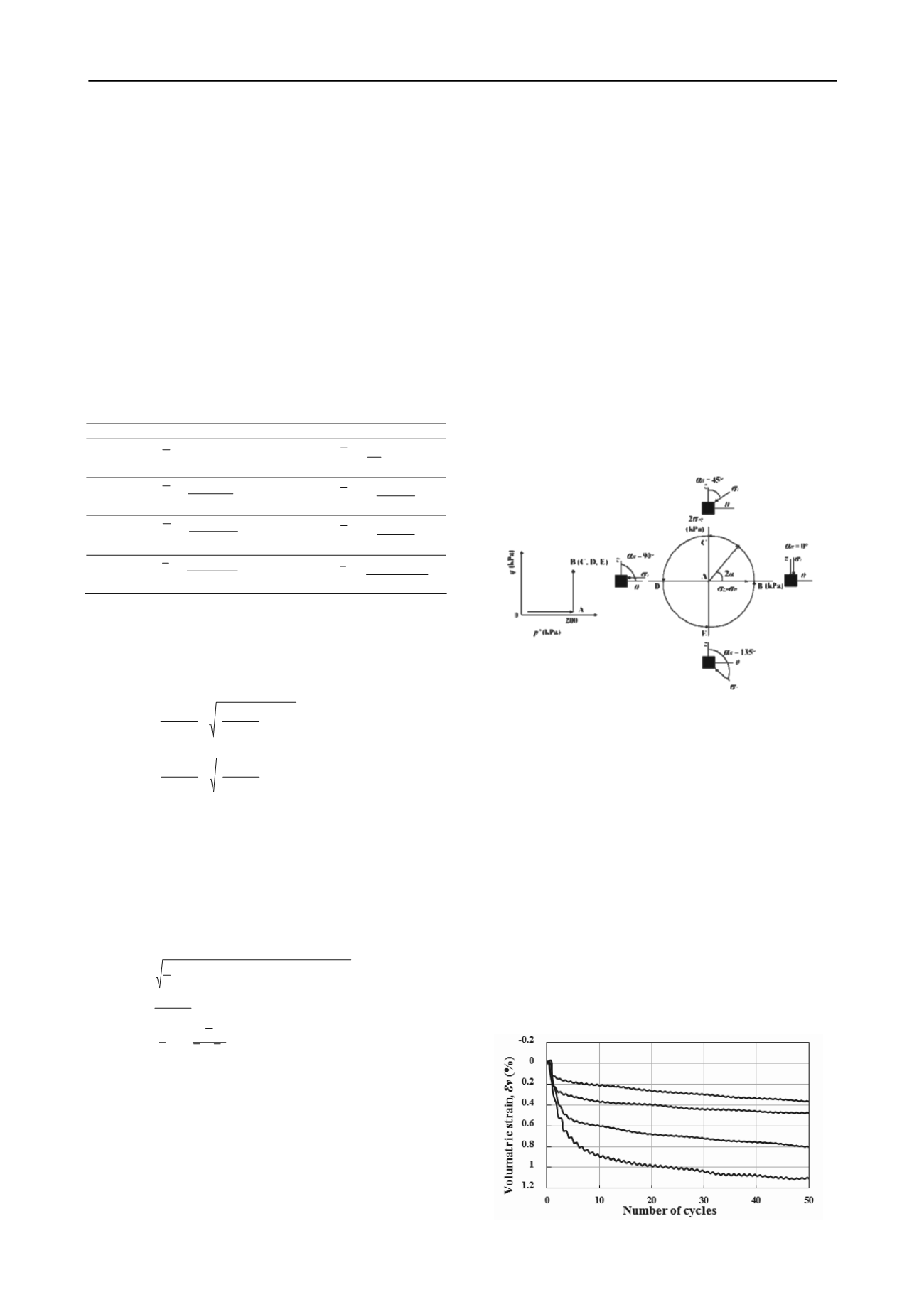

In this study, the HCA, developed by GDS Instruments Ltd, was

used. For the details of the testing system, see Cai (2010). The

hollow cylindrical specimen had an inner radius of 30 mm,

outer radius of 50 mm and height of 200 mm. As shown in

Figure 1, the loading of the specimen consisted of an axial load

W

, torque

M

T

, inner cell pressure

P

i

and outer cell pressure

P

o

.

The application of these stress components enables the control

of axial stress

σ

z

, radial stress

σ

r

, circumferential stress

σ

θ

, and

shear stress

σ

θz

, on an element in the wall of the hollow

cylindrical specimen.

Since the stresses are not uniformly distributed across the

sample wall especially with unequal inner and outer cell

pressures, it is necessary to compute average values. The

equations used to calculate the average stress and strain

components are listed in Table 1.

Table 1. Equations used to calculate stresses and strains (Hight et al.

1983)

r

o

: outer radius,

r

i

: inner radius,

H

: height of specimen,

w

: axial

displacement,

u

o

: outer radius displacement

u

i

: inner radius

displacement,

θ

: torsional angle.

The major principal stress, intermediate principal stress and

minor principal stress are calculated by using Eqs. (1a)-(1c).

2

2

1

2

2

z

z

z

r

2

2

2

3

2

2

z

z

z

The stress path in drained tests can be characterized by four

independent parameters, namely the mean principal effective

stress

p’

, deviatoric stress

q

, intermediate principal stress

parameter

b

and the angle

α

σ

between the major principal stress

σ

1

and the vertical direction. These parameters are defined in

Eqs. (2a)-(2d).

3

'

3

'

2

'

1

p

2

3

2

2

3

1

2

2

1

)

( )

( )

(

2

1

q

'

3

'

1

'

3

'

2

b

z

z

2

tan

2

1

1

2.2

Sample preparation method

The tests were performed on dense Leighton Buzzard (Fraction

B) sand, with an initial relative density of

D

ri

≈70%. Leighton

Buzzard sand is made up of sub-rounded particles and mainly

composed of quartz. It has a specific gravity of 2.65, mean

particle size of 0.62 mm, minimum void ratio of 0.52 and

maximum void ratio of 0.79 (Cai 2010). The water

sedimentation method was employed to prepare all the samples.

After saturation, with a Skempton's B value greater than 0.96,

specimens were consolidated isotropically under an effective

confining stress of

p’

=200 kPa.

2.3

Stress paths of drained rotational shear tests

The stress paths in

q

-

p’

and deviatoric stress planes are shown

in Figure 2. In the deviatoric stress plane, the vector from the

origin has a length equal to the magnitude of the deviatoric

stress

q

and makes an angle of 2

α

, which is twice the angle of

the major principle stress

σ

1

makes with the vertical direction.

During the tests, the samples were first subjected to monotonic

shearing in the vertical direction up to a specified stress ratio

(

η

=0.8, 0.9, 1.0, 1.1) while keeping the effective mean stress

p’

constant (A→B). After that the principal stress axes were

rotated counter clockwise (B→C→D→E→B) under drained

condition, while keeping the deviatoric stress constant and

maintaining the effective mean stress

p’

=200 kPa and the

intermediate principal stress parameter

b

=0. To ensure full

discharge of water from the specimen, the major principal stress

direction

α

σ

was rotated at a slow rate of 2°/min.

Figure 2. Stress paths for rotational shear test (Nakata et al. 1998).

3 TEST RESULTS AND DISCUSSIONS

3.1

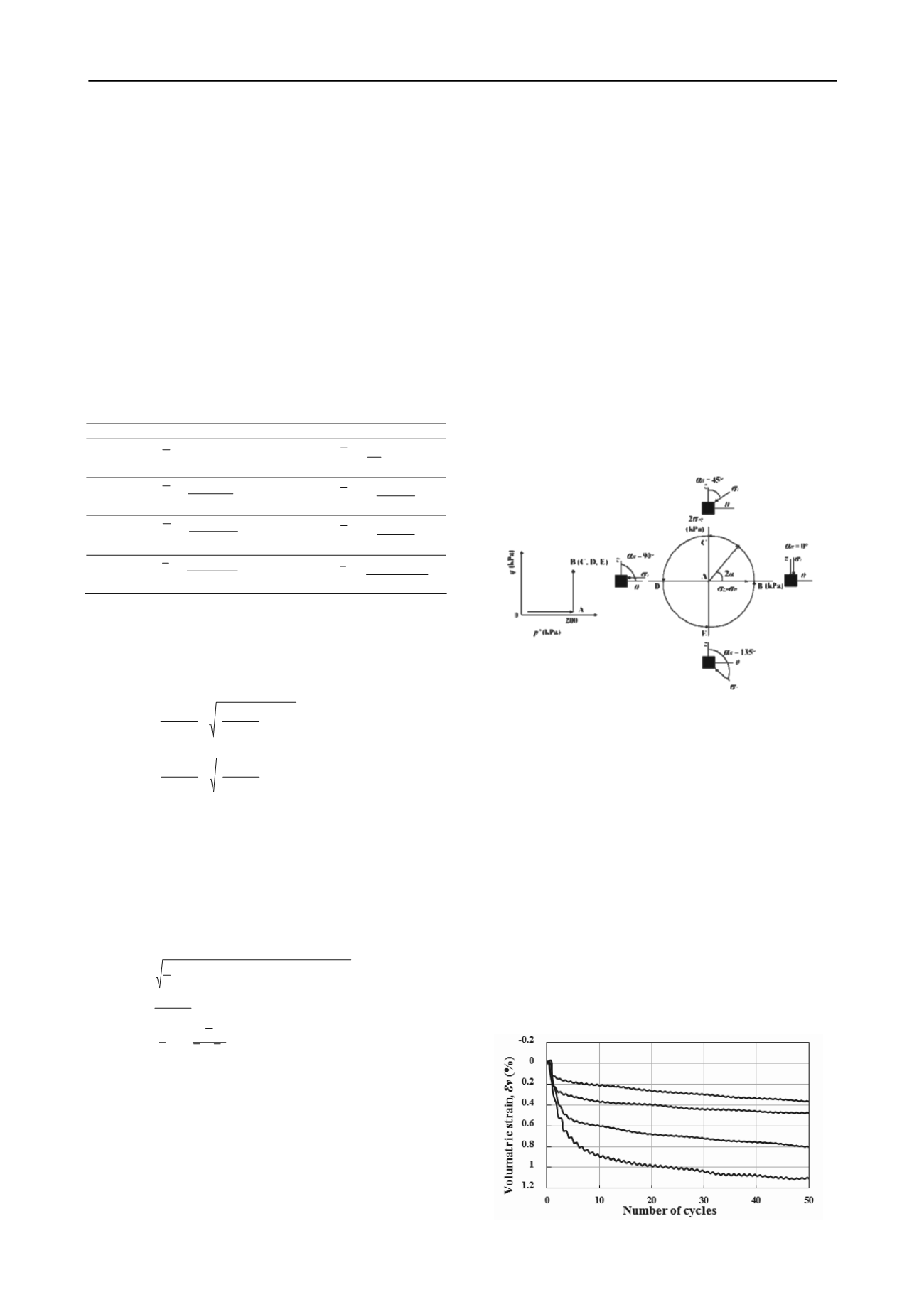

Development of volumetric strain

The evolutions of the volumetric strain

ε

v

with the increasing

number of cycles for rotational shear tests are shown in Figure

3. A positive value along the vertical axis indicates contraction

and negative indicates dilation. Although the magnitudes of

principal stresses were maintained constant during each test,

contractive volumetric strain accumulated due to the rotation of

principal stress directions. It can be observed that most of the

volumetric strain occurs during the first few cycles and its

accumulation rate tends to decrease as the number of cycles

increases. It is clear that the effect of stress ratio on the

development of the volumetric strain is significant under

otherwise identical conditions. For all the four tests, the amount

of the contractive volumetric strain at the same number of

cycles increases with the increase in the stress ratio

η

.

Direction

Stress

Strain

Vertical

2

2

2

2

2

2

)

(

i

o

i i

oo

i

o

z

r r

rP rP

r r

W

H

w

z

Circum-

ferential

i

o

i i

oo

r r

rP rP

i

o

i

r r

u u

0

Radial

i

o

i i

oo

r

r r

rP rP

i

o

i

r

r r

u u

0

Shear

)

(2

3

3 3

i

o

T

z

r r

M

)

(3

)

(2

2

2

3

3

i

o

i

o

z

r rH

r r

(1a)

(1b)

(1c)

(2a)

(2b)

(2c)

(2d)

η

=0.8

η

=0.9

η

=1.0

η

=1.1

Figure 3. Stress paths for rotational shear test.