3511

Technical Committee 105 /

Comité technique 105

models (Yin & Graham 1994) and v is the specific volume.

From Eq. 1

ψ

/v can be expressed as,

'

0

'

0

1

0

0

ψ

ψ

=

v 1+ (

ψ

/

ε

)Ln[(t + t ) / t ]

(2)

Where

∆ε

1

is the limit creep strain,

ψ

0

΄

is the value of

ψ

/v at the

reference time. Eq. 2 dictates that

ψ

/v is not a constant and

decreases with creep time, and also it can be stated that

ψ

/v is

dependent on the stress level.

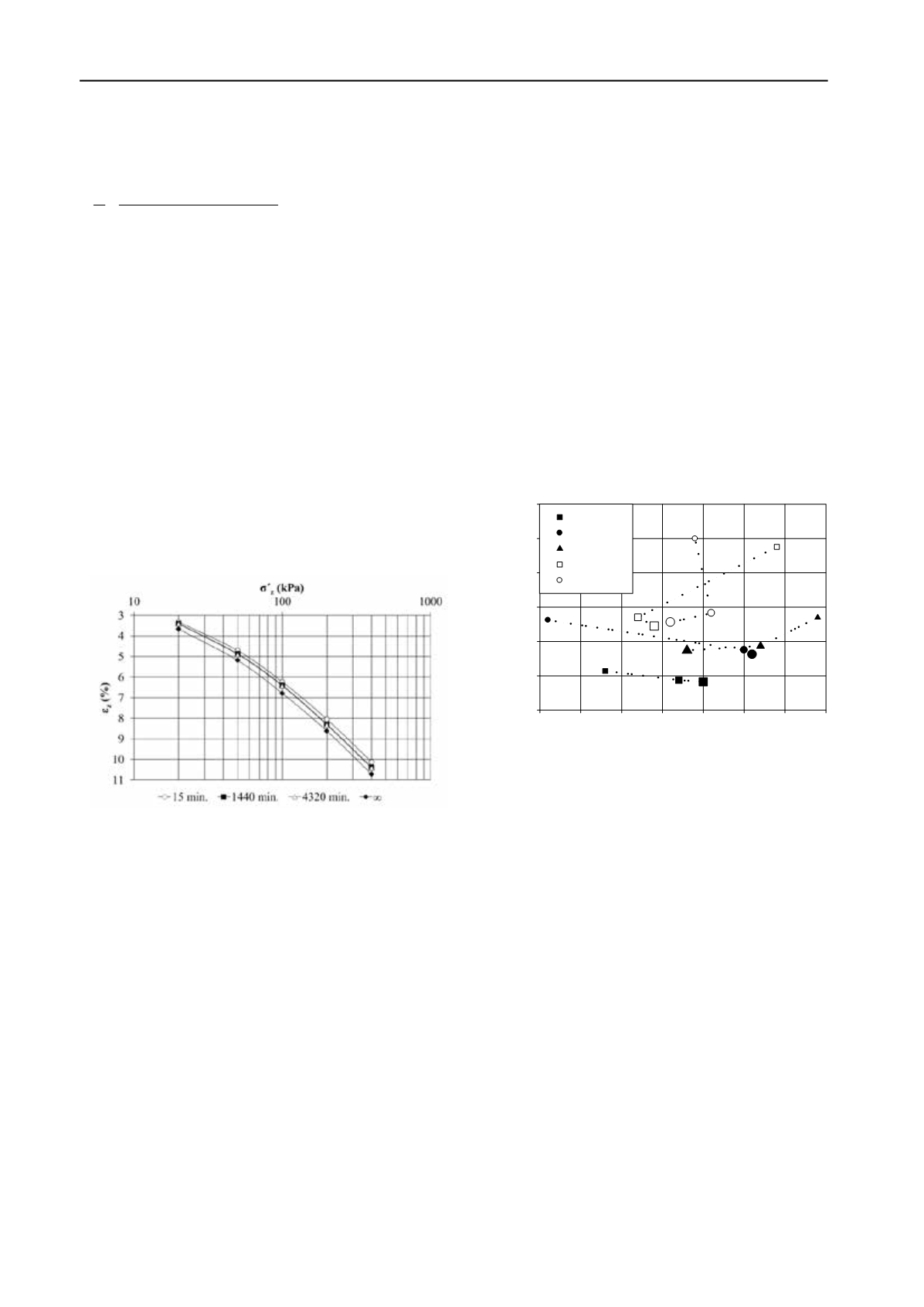

In this study, the creep function by Yin (1999) was used to

interpret the time-dependent creep behavior, prevalent in the 1-

D consolidation tests. Vertical strain-time relations were

configured into time lines by applying Yin (1999) approach. An

example of this application is given in Fig. 3 for the test

conducted up to the 400 kPa stress level and this load was kept

on the sample for 4320 minutes. Only creep phases of the

consolidation tests were considered in this study and the results

of the tests on the reconstituted kaolin clay specimens indicated

that end of primary consolidation times correspond to

approximately 15 minutes or less. The parameters,

ψ

0

΄

and

∆ε

1

,

and thus the time lines were calculated for all the test groups

with load applications up to 20, 50, 100 200 and 400 kPa stress

levels and 15, 1440 and 4320 minutes of duration. In

accordance with Yin (1999) approach, limit time lines were also

determined and displayed on the graphs.

Figure 3. Time lines for the 400 kPa test.

5

Ψ

/V AND PF RELATION

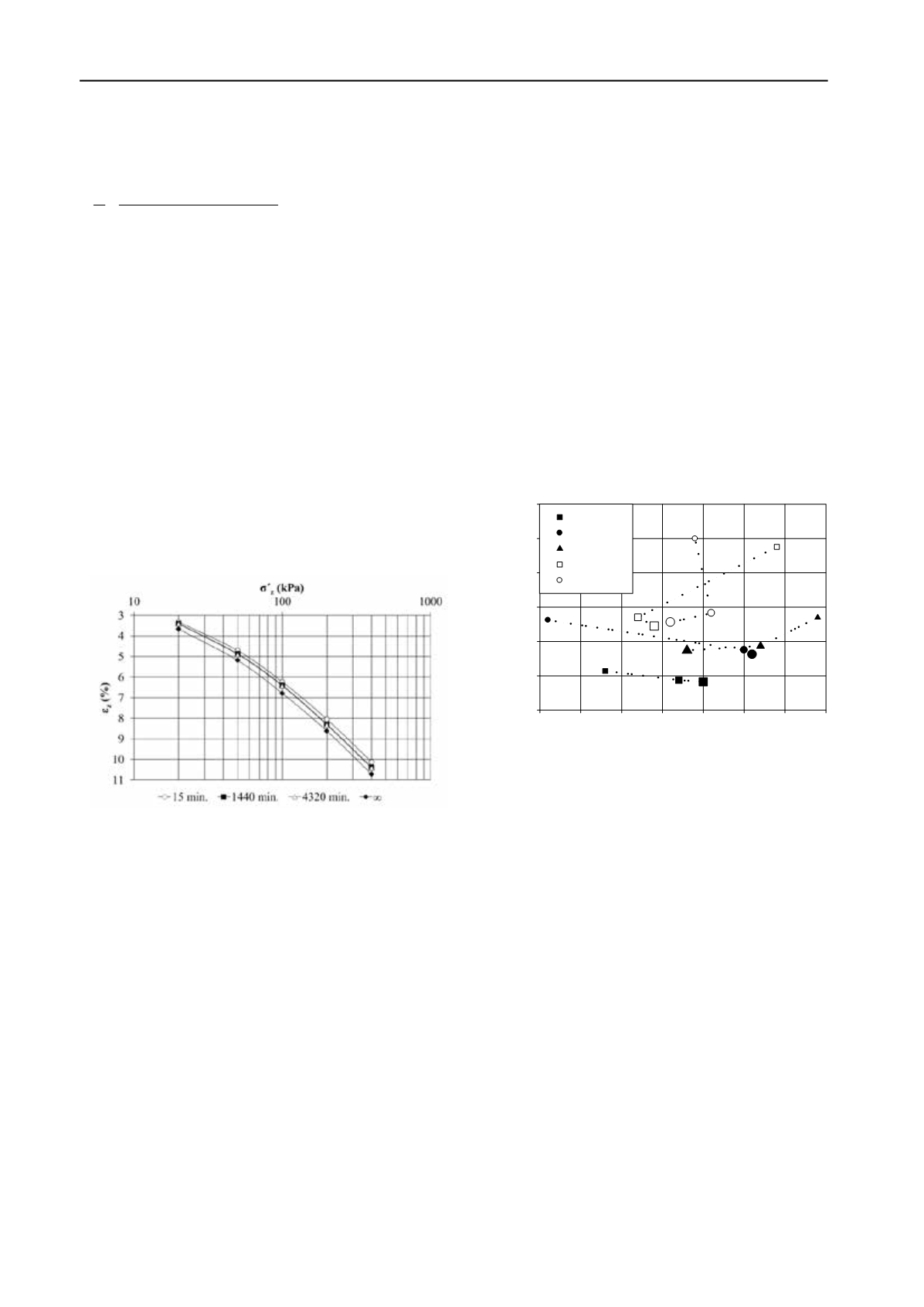

As stated before, Eq. 2 gives the creep parameter,

ψ

/v

decreasing with time. In the same sense, the gradation curves

given in Fig. 2 imply the variation of PF values with time, but

the variation may change its direction either towards size

enlargement or degradation. Therefore, it can be argued that a

correlation between

ψ

/v and PF may exist. Such a correlation

was searched for by comparing the results of the tests conducted

in the scope of this research programme. Some examples of test

results were presented in Figs. 2 and 3. The summary of the

results obtained with this approach are given in Fig. 4 which

shows

ψ

/v - PF relations for each load increment and all load

durations. In Fig. 4, the symbols depicting the data points along

a relationship corresponding to a load increment gets larger in

size as load duration gets longer (e.g. the smallest size

corresponds to 15 minutes and gets larger towards 1440 and

4320 minutes). The relationships displayed in Fig. 4 can be

interpreted either in terms of the tendencies of clump formation

or clump disintegration depending on the direction of variation

in PF values. It can be seen in Fig. 4 that, at low stress levels,

such as 20 and 50 kPa’s, PF increases as load duration

increases. As a matter of course, increases in PF correspond to

clump disintegration. In the scope of the findings presented in

Fig. 4 an opposite behavior seems to be present in case of

higher stress application, 100, 200, 400 kPa stress states. In case

of higher stress states PF values decrease as time proceeds;

implying structure reconfiguration accompanied by clump

formation. Referring to the creep rate parameter it can be stated

that,

ψ

/v decreases with time at all the stress levels. The

correlation between

ψ

/v and PF is negative at stress levels 20

and 50 kPa’s, but positive at stress levels 100, 200 and 400

kPa’s. If the variation of both of the parameters;

ψ

/v and PF

with respect to time was considered, it seems that, both of these

decreases as time proceeds. Moreover,

ψ

/v values are greater at

high stress levels compared to low stress levels, provided that

the load duration is the same for each test. In terms of the sign

of correlation between

ψ

/v and PF it can be stated that, the

stress level, 100 kPa acts as a threshold and at this stress state

and towards higher stress states, the correlation changes sign

from negative to positive. This argument is in accordance with

the findings of McConnachie (1974) who studied the changes in

the sizes of the domains against a large range of pressure; from

0.1 kPa to 100000 kPa’s. McConnachie pointed out the

possibility of occurrence of a fundamental change in the

mechanism of consolidation between the pressures 10 and 100

kPa”.

Percent Finer (%)

50 55 60 65 70 75 80 85

Ψ / ν

(x10 -4 )

0

2

4

6

8

10

12

20 kPa

50 kPa

100 kPa

200 kPa

400 kPa

Figure 4. Relations obtained for the tests at different stress levels.

6 CONCLUSIONS

A specifically designed testing programme was conducted to

investigate the interaction between macro and micro

mechanisms that occur during time dependent consolidation

process. The testing programme consisted five sets of 1-D

oedometer tests; each with a different maximum stress level.

Three duration periods were applied for each set of the tests.

Micrographs were taken at the end of all of the fifteen tests and

quantified in terms of the variation of clump sizes present at any

stress level and time. The results were presented by using an

approach similar to the construction of gradation curves. In

order to analyze the gradation curves, in terms of degree of

fineness, a parameter was defined which is called as Per cent

Finer (PF), to give the percentage of clusters finer than a

specific size that was chosen to act as a threshold. Macro

measurements made during the application of the oedometer

tests and micro measurements obtained through the

quantification process applied on the micrographs provided two

parameters; creep rate parameter,

ψ

/v and Per cent Finer, PF.

The possibility of existence of an interrelationship between

ψ

/v,

and PF was then searched for, as, both of these parameters vary

with respect to creep time. The results can be interpreted in

terms of the existence of a correlation. However, further

evidence supported by larger sets of data is required. Current

results can be summarized as; the creep rate parameter,

ψ

/v

decreases with time at all the stress levels. The correlation

between

ψ

/v and PF is negative at stress levels 20 and 50 kPa’s,