3500

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

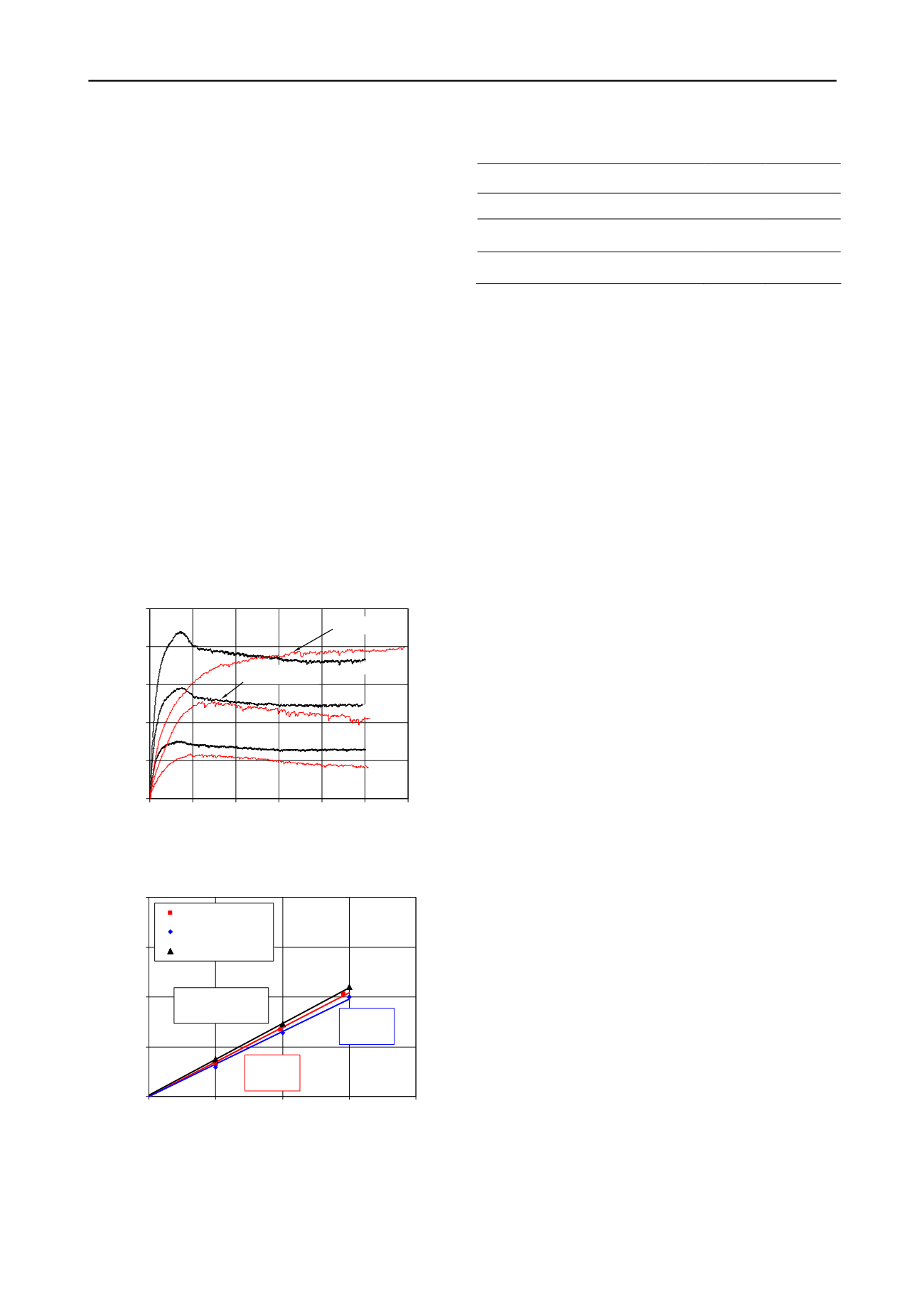

The shear stress-shear displacement curves obtained with the

large scale direct shear tests tend to exhibit peak shear strength,

not evident in the results achieved with the conventional

apparatus. The maximum shear strengths reached with two

devices are relatively close however they were achieved for

lower values of the normalized shear displacement in the larger

box.

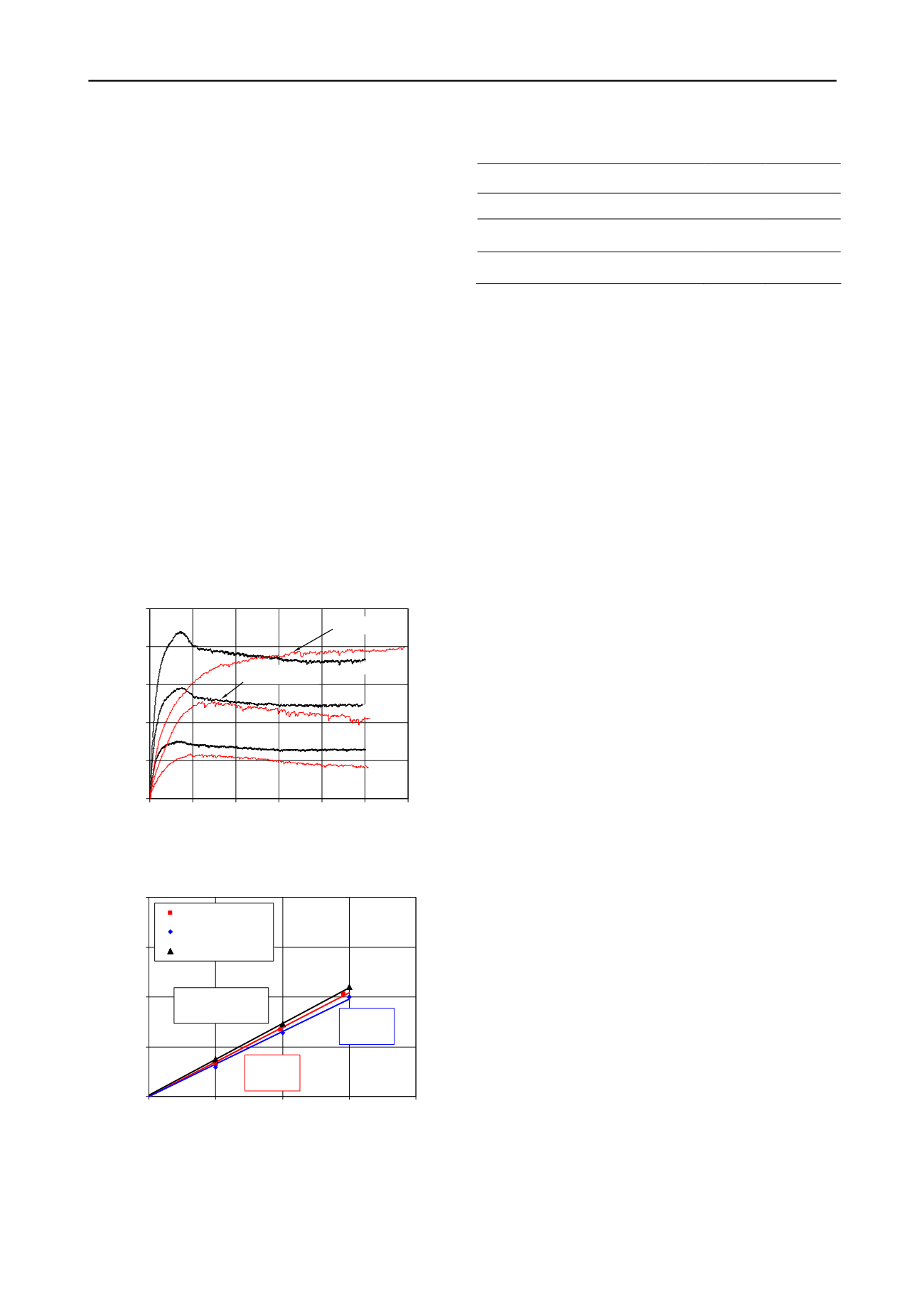

Figure 10 compares the failure envelope obtained with

simple shear tests for reinforced sand and the failure envelopes

achieved in the direct shear tests (DS) performed with both

devices (60 mm

×

60 mm and 300 mm

×

600 mm) to

characterize the interface between the sand and the geotextile.

It should be noted that, while the direct shear tests

characterize the interface between the two materials (sand and

geotextile), the simple shear tests analyze the behaviour of the

reinforced sand. Despite this difference, the analysis of Figure

10 shows that the shear strength of the reinforced sand

approaches the shear strength of the sand/geotextile interface.

Table 1 summarizes the values of the friction angle and

apparent adhesion relating to the failure envelopes for the direct

shear tests and simple shear tests (reinforced sand).

Comparing the interface shear strength (evaluated with direct

shear tests), it was found that it tends to be higher when large

scale apparatus was used. As mentioned previously, the shear

strength of the reinforced sand reached with simple shear tests

approaches the shear strength of the interface between the two

materials obtained with direct shear tests. The friction angle of

the reinforced sand is within the range of values achieved with

the two direct shear devices.

0

25

50

75

100

125

0 0.02 0.04 0.06 0.08 0.1 0.12

∆

shear

/L

Shear stress (kPa)

300mmx600mm

60mmx60mm

50 kPa

150 kPa

100

Figure 9. Comparison of shear stress-shear displacement curves

obtained with two direct shear test devices.

τ

= 0.6932

σ

R

2

= 0.9961

τ

= 0.6525

σ

R

2

= 0.9939

τ

= 0.7208

σ

+ 1.4161

R

2

= 0.9998

0

50

100

150

200

0

50

100

150

200

Normal stress(kPa)

Shear stress (kPa)

Simple Shear

DS 60mm x 60mm

DS 300mm x 600mm

Figure 10. Comparison of the failure envelopes of sand SP49 reinforced

with geosynthetic GC100 obtained with three shear devices.

Table 1. Comparison of the shear strength parameters reached with

different devices.

Test

adhesion

(kPa)

Friction

angle (º)

Direct Shear Test (300mm

×

600mm)

1.4

35.8

Direct Shear Test (60mm

×

60mm)

-

33.1

Simple Shear Test

-

34.7

6 CONCLUSIONS

Based on the analysis and interpretation of the results of direct

shear tests performed to characterize the interface between a

silica poorly graded sand and a high strength geotextile and the

results achieved by simple shear tests carried out with the sand

reinforced with one layer of geotextile, the following

conclusions can be drawn.

From the direct shear tests it was concluded that the large

scale device overestimates the shear strength of the soil-

geosynthetic interface comparatively to the results obtained

with the conventional direct shear apparatus. Notice, however,

that the large scale direct shear device should represent more

accurately the real behaviour of the interface. Nevertheless, the

differences between the results obtained with the two devices

are not significant.

Although the characterization reached by the simple shear

tests is distinct from that of the direct shear tests, it can be stated

that the shear strength of the anisotropic material (sand and

geosynthetic) approaches the shear strength of the interface

between the two materials.

The conclusions presented are also valid for interfaces

between other materials (Vieira, 2008).

7 ACKNOWLEDGEMENTS

The authors would like to thank the financial support of

Portuguese Science and Technology Foundation (FCT) and

FEDER, Research Project FCOMP-01-0124-FEDER-009750 -

PTDC/ECM/100975/2008.

8 REFERENCES

Evgin, E. & Fakharian, K., 1998, Cyclic Rotational Simple- Shear

Behaviour of Sand-Steel Interfaces. Soils and Foundations, 38(2):

191-199.

Hsieh, C. & Hsieh, M.-W., 2003, Load plate rigidity and scale effects

on the frictional behavior of sand/geomembrane interfaces.

Geotextiles and Geomembranes, 21: 25-47.

Lee, K. M. & Manjunath, V. R., 2000, Soil-geotextile interface friction

by direct shear tests. Canadian Geotechnical Journal, 37: 238-252.

Ling, H. I., Burke, C., Mohri, Y. & Matsushima, K., 2002, Shear

Strength Parameters of Soil-Geosynthetic Interfaces Under Low

Confining Pressure Using a Tilting Table. Geosynthetics

International, 9(4): 373-380.

Liu, C.-N., Ho, Y.-H. & Huang, J.-W., 2009, Large scale direct shear

tests of soil/PET-yarn geogrid interfaces. Geotextiles and

Geomembranes, 27(1): 19-30.

Palmeira, E. M., 1988, Discussion on direct shear tests on reinforced

sand. Geotechnique, 38(1): 146-148.

Uesugi, K. & Kishida, H., 1986, Fricional resistance at yield between

dry sand and mild steel. Soils and Foundations, 26(4): 139-149.

Vieira, C. S., 2008, Geosynthetic reinforced soil retaining walls and

slopes. Seismic behaviour and design methodologies, PhD Thesis,

Civil Engineering Department, University of Porto, 575 p (in

Portuguese).

Vieira, C. S., Lopes, M. L. & Caldeira, L. M., 2013, Sand-geotextile

interface characterization through monotonic and cyclic direct shear

tests. Geosynthetics International (accepted for publication, Vol.

20, No. 1).