3498

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

displacement controlled cyclic tests was designed (Vieira et al.

2013).

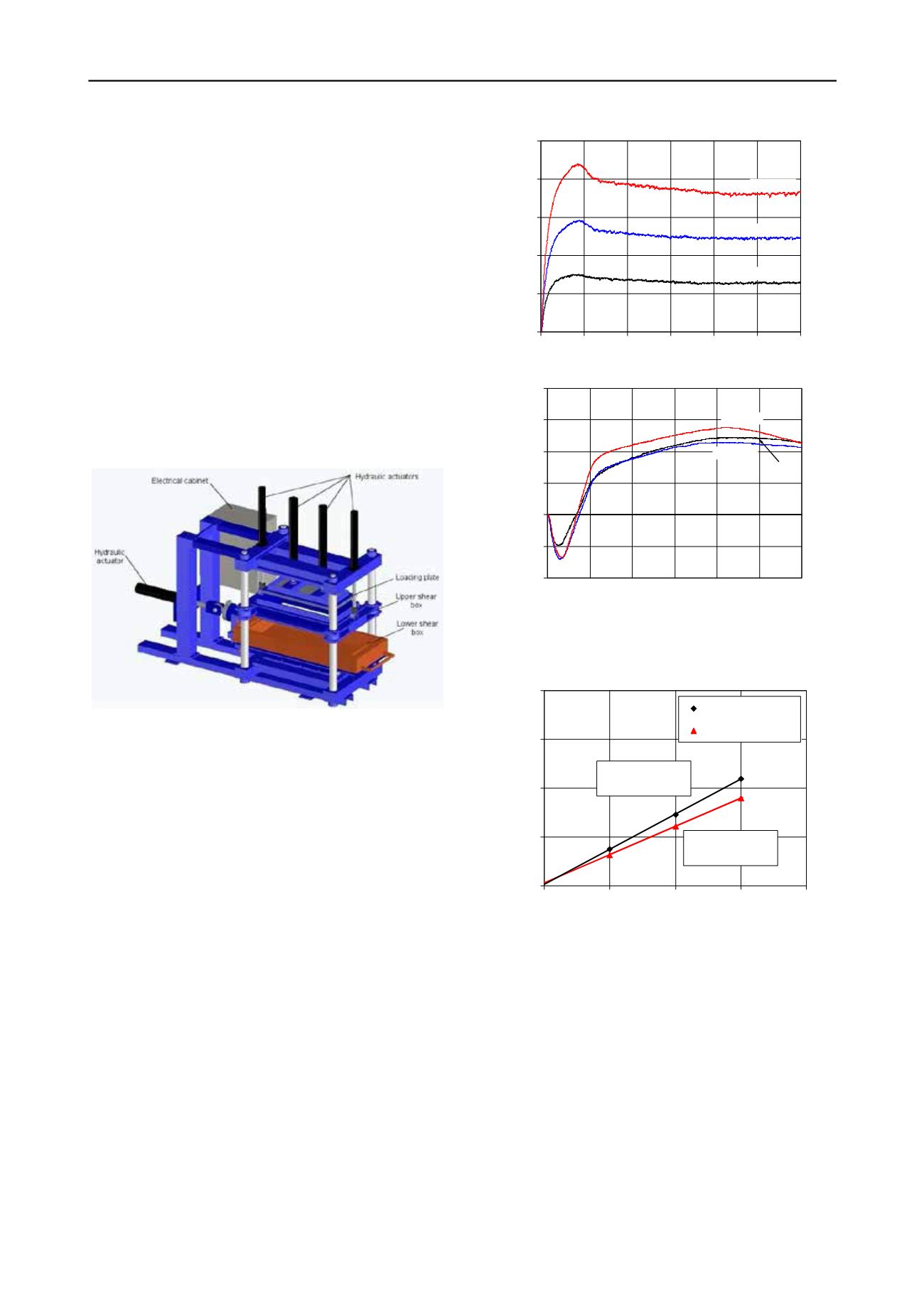

The developed large scale direct shear device is based on a

hydraulic actuation with closed loop command computer

control. The apparatus consists of the shear box, a support

structure, five hydraulic actuators and respective fluid power

unit, an electrical cabinet, internal and external transducers and

a computer. Figure 2 shows a schematic view of the apparatus.

The shear box comprises an upper box, fixed in the

horizontal directions, with dimensions of 300 mm × 600 mm in

plant and 150 mm height, and a lower box, with dimensions of

340 mm × 800 mm in plan and 100 mm height, rigidly fixed to

a mobile platform running on low friction linear guides. More

details can be found in Vieira

et al.

(2013).

The direct shear tests were performed with a rigid base

placed on the lower box (constant contact area tests). The sand

was placed inside the upper shear box, at its air-dried water

content, with relative density (I

D

) of 70%. It was compacted in

two thick layers with 25 mm height to the target unit weight.

The tests were conducted with a constant displacement rate of

1 mm/min at normal stresses of 50, 100 and 150 kPa.

Figure 2. Schematic view of the direct shear test apparatus.

3.2

Direct shear tests results

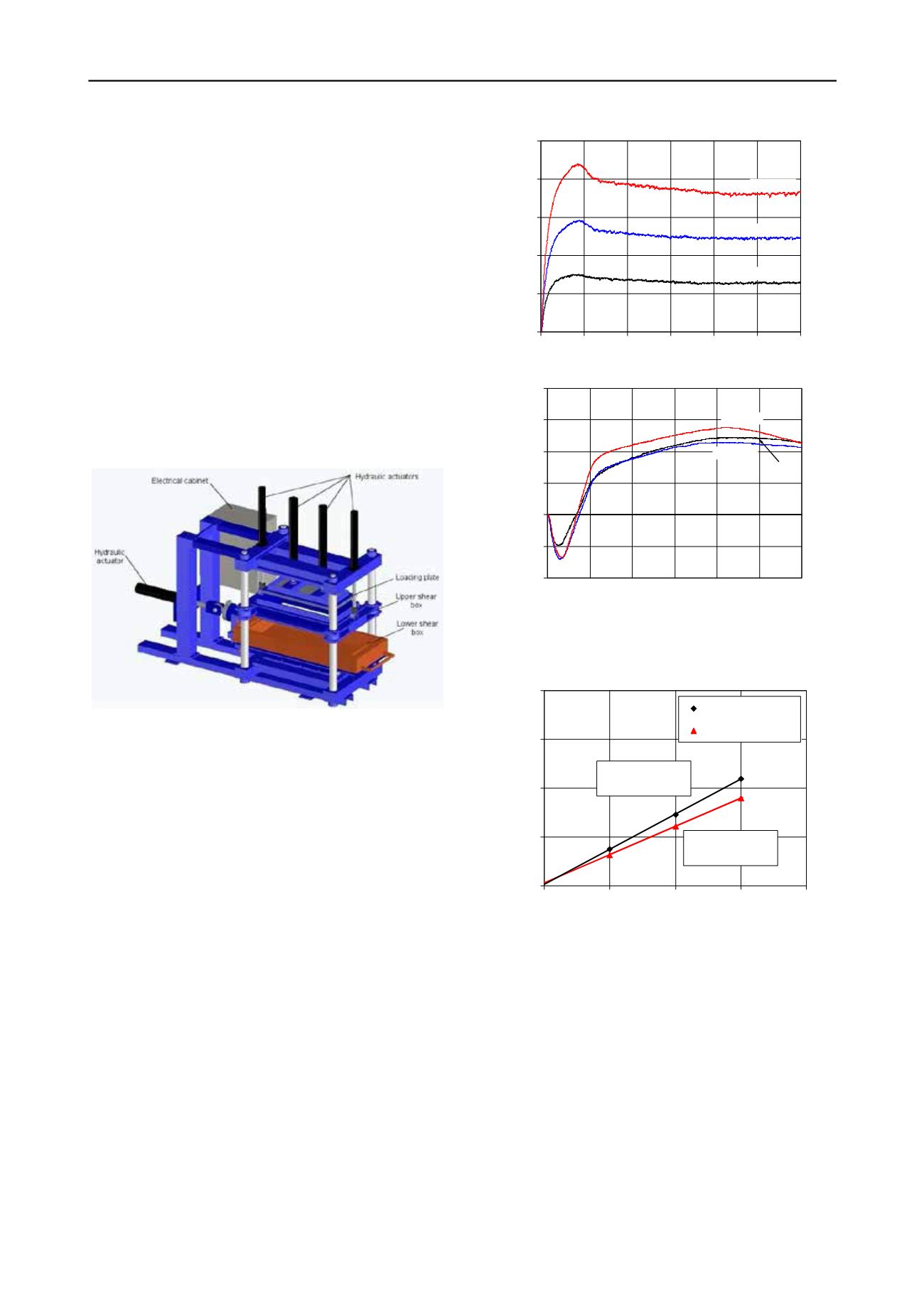

The evolution of the shear stress and the vertical displacement

of the rigid plate centre, as function of the shear displacement,

for the sand SP49/geocomposite GC100 interface is shown in

Figure 3.

The shear stress-shear displacement curves (Figure 3a) show

a well-defined peak shear strength, which was recorded for

shear displacements that increased with the confining pressure.

As expected, initially, the sand exhibited a contraction followed

by a dilating phase (Figure 3b). After reaching the peak of the

interface shear strength, the vertical displacement progress

during shear for confining pressure of 100 kPa is similar to the

one observed for the lower stress (50 kPa).

Figure 4 presents the peak and the large displacement shear

strengths for the three values of the confining pressure (50 kPa;

100 kPa, 150 kPa), as well as the corresponding linear best fits.

Following Coulomb failure criterion, the SP49/GC100 interface

presented an apparent adhesion c

a,p

= 1.4 kPa and a peak friction

angle

δ

p

= 35.8º. The large displacement strength can be defined

by an apparent adhesion c

a,cv

= 3.0 kPa and friction angle

δ

cv

= 30.2º. The failure envelopes show an apparent adhesion

for the sand/geotextile interface due to the nonlinearity of the

relationship between the shear strength and the normal stress at

lower confining stresses. Even so, the values for this parameter

can be considered without great significance.

Notice that, the apparent adhesion has also been reported by

other authors for sand/geosynthetic interfaces (Ling

et al.

2002;

Liu

et al.

2009).

0

25

50

75

100

125

0.0 10.0 20.0 30.0 40.0 50.0 60.0

Shear displacement (mm)

Shear stress (kPa)

50 kPa

150 kPa

100 kPa

(a)

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.0 10.0 20.0 30.0 40.0 50.0 60.0

Shear displacement (mm)

Vertical displacement (mm)

50 kPa

100 kPa

150 kPa

(b)

Figure 3. Direct shear tests results for different normal stresses (50, 100

and 150 kPa): (a) shear stress-shear displacement; (b) vertical

displacement-shear displacement.

τ

= 0.5814

σ

+ 2.9838

R

2

= 0.9999

τ

= 0.7208

σ

+ 1.4161

R

2

= 0.9998

0

50

100

150

200

0

50

100

150

200

Normal stress (kPa)

Shear stress (kPa)

Peak

Large displacement

Figure 4. Peak and large displacement shear strengths as a function of

the applied normal stress.

4 CHARACTERIZATION OF GEOSYNTHETIC

REINFORCED SAND BY SIMPLE SHEAR TESTS

In this work a simple shear device Norwegian Geotechnical

Institute type, model Geonor h-12 was used. It is a linear simple

shear apparatus, which differs from the conventional direct

shear devices since tilting elements delimit the vertical

boundaries of the specimens, allowing a more uniform

deformation of the soil and the rotation of principal stresses.

Besides the failure planes are not imposed.

The specimens are cylindrical, with a height of 16 mm and a

diameter of about 80 mm, enclosed in a wire-reinforced

membrane. In the tests of reinforced sand the thickness of

geosynthetic was deducted from the height of specimen to

determine the amount of sand corresponding to the desired