3510

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2 EXPERIMENTAL METHOD

One dimensional consolidation tests were conducted with

commercial kaolinite. Reconstituted kaolin clay slurry

specimens were prepared at 26% water content, compared to the

liquid limit of 22%. The test programme was composed of 15

consolidation tests. These fifteen tests can be grouped into five,

according to the five different maximum stress levels that were

applied at the end of the tests, which were 20, 50, 100, 200 and

400 kPa’s. In addition to this grouping, three sub-groupings

were defined according to the duration of application of

maximum stress levels; which are 15, 1440 and 4320 minutes.

In each of these tests, starting with an initial stress level of 2.5

kPa, loading increments were increased with a ratio of 2, and

each was sustained for 24 hours. At the maximum vertical

pressure stage specific to the group, (the tests were ended

abruptly for sampling at different times (15, 1440 and 4320

minutes) for each of the five samples that constitute one test

group. Dimensions of the samples extracted at the end of these

durations is1cmx1cm. Retrieved vertical undisturbed specimens

were used in the ESEM analyses. Thus, there were 15

specimens to be used for observation of the micro behavior,

each having different “consolidation level-maximum

consolidation pressure” combinations. Three photographs were

taken from each of the specimens and thus in total there were 45

photographs to be analyzed. Image analyses were conducted to

investigate the implications of the influence of both the load

increments and consolidation degrees on the micromechanical

behavior.

3 IMAGE ANALYSIS

3.1

The Method

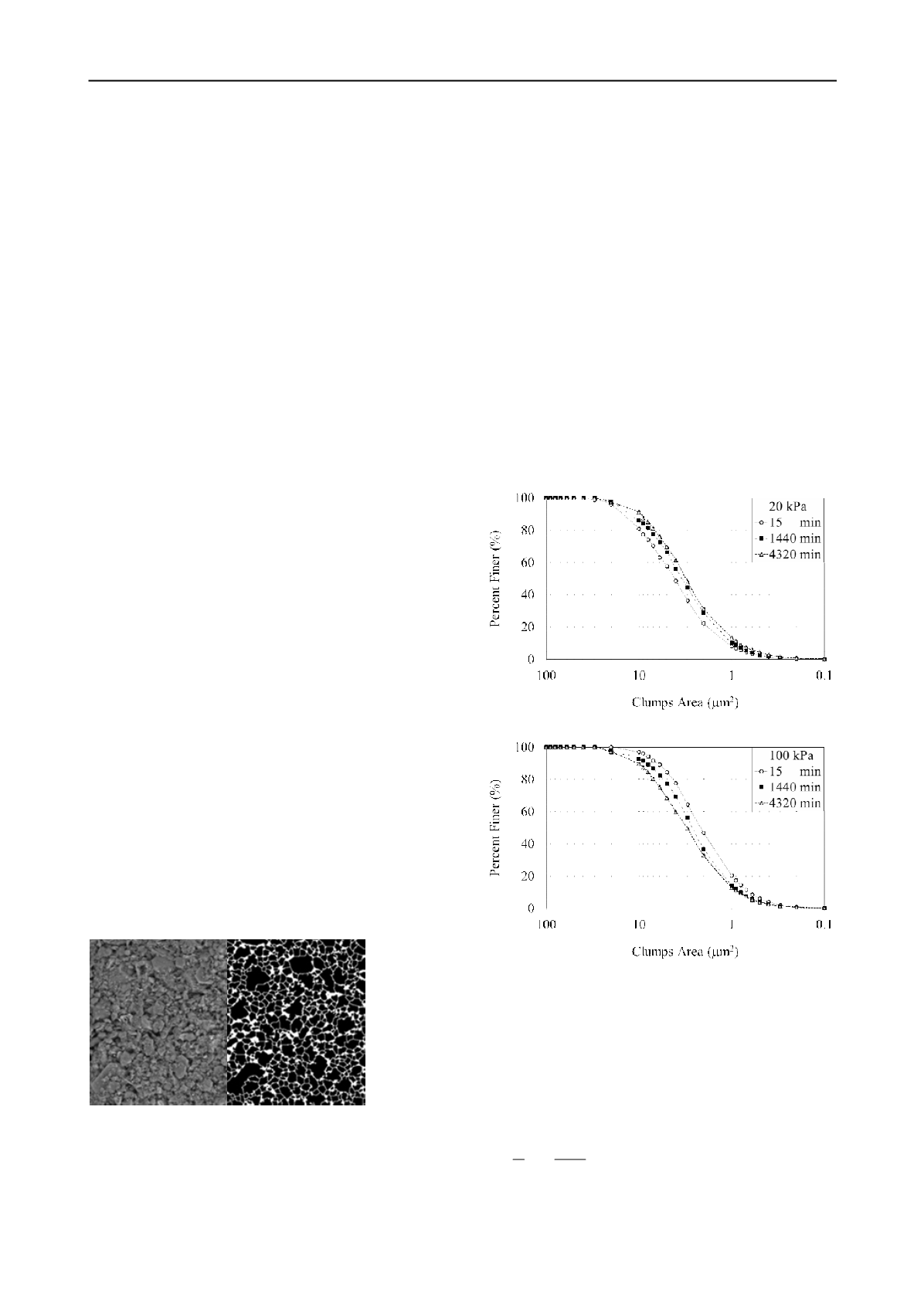

Image processing was conducted using the open source program

ImageJ (Rasband 2009). Isodata threshold algorithm of 256

grey level images was used to distinguish clay aggregates from

inter-aggregate voids. Brightness value of pixels above the

threshold was established as indicating clay aggregates. This

image was then converted to a binary image in which black and

white represents clay aggregates and inter-aggregate voids

respectively. The pixel size in the ESEM micrographs was

8.47*10

-2

µ

m which corresponds to a size in the range of large

enclosed pores within groups (macro voids). Binary images

were segmented by the watershed function. Using this analysis,

particles of all recordable sizes can be detected (Yigit 2010,

Yigit and Cinicioglu 2011). Photographs show the planes that

have normal, orthogonal to the loading direction, therefore

reflect the positioning of the particles on the vertical plane. A

raw photograph and its processed version are shown in Fig.1.

Figure 1. Raw (left hand side) and Processed Micrographs.

3.2

Interpretation of structure in terms of clump sizes

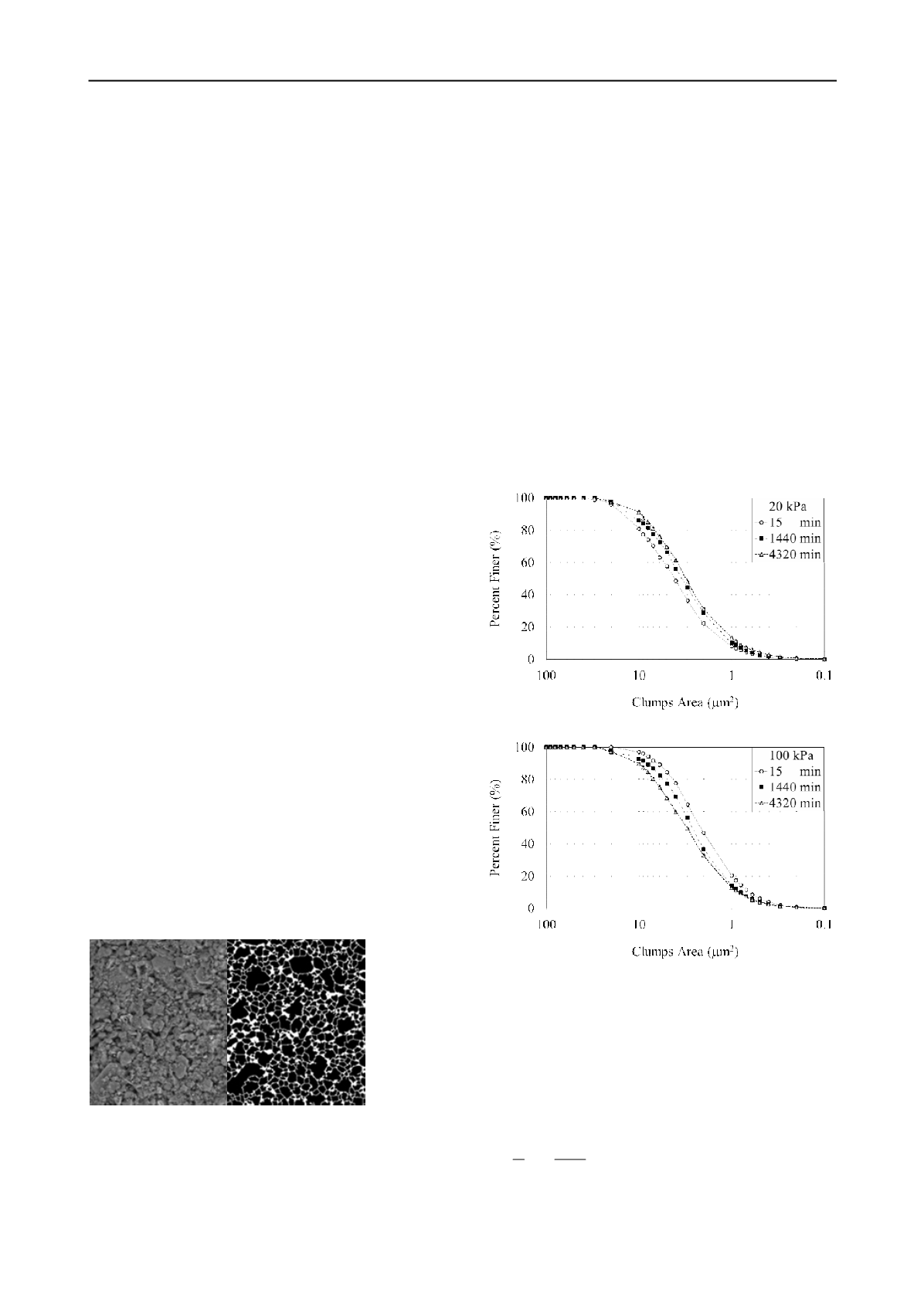

The gradation curves were found by applying a technique

similar to that used in the presentation of sieve analyses results,

but in this case the application was conducted on digitized

micrographs. In this context, discrete clusters were detected and

then grouped in the order of their areal sizes. The applied range

for particle areas is between 0.1-100

µ

m

2

. By dividing the total

area of each size group to the total area of the entire clusters,

“per cent retained” values were found and the cluster gradation

curves were drawn in terms of per cent passing against area

sizes in decreasing order, for a specific loading duration, as

shown in Figs. 2.a and 2.b for load durations of 15, 1440 and

4320 minutes.

In order to analyze the gradation curves, in terms of degree

of fineness, a threshold cluster size was chosen and the per cent

passing value corresponding to the chosen clump size was

defined as Per cent Finer (PF), to give the percentage of clusters

finer than the threshold. Therefore increases in PF values are

associated with disintegration into finer sizes and decreases are

associated with clump formation into larger sizes. Fig. 2.a and

2.b give two different tendencies in cluster size variation. For

load increment of 20 kPa in Fig. 2.a, clusters become finer with

increasing load duration but in Fig. 2.b, for 100 kPa load

increment, a reverse order is apparent; implying clump

aggregation as the time proceeds. It can be argued that, the

variation in cluster sizes is influenced by the stress state, time

and the initial structural state respecting to the starting state of

the current load increment.

Figure 2. Variation of clump gradation curves for (a) 20 kPa and (b) 100

kPa load increments with loading duration.

4 TIME DEPENDENT BEHAVIOUR

Yin (1999), suggested a non-linear creep function with a limit

creep strain. The function proposed by Yin (1999) and

reproduced in Eq. 1 is advantageous due to its ability to

represent nonlinear creep behavior of soils and its simplicity.

0

0

ψ

t + t

ε

= Ln

v

t

(1)

where,

∆ε

is the creep strain, t is the creep time for

∆ε

, t

0

is the

reference time,

ψ

/v is the creep parameter used in the 1-D EVP