3499

Technical Committee 101 - Session II /

Comité technique 101 - Session II

relative density (I

D

= 70%). The sand was deposited in two

layers, being the geosynthetic placed between them. Figure 5

presents a reinforced sand specimen already placed on the

simple shear device.

Figure 5. Geosynthetic reinforced sand specimen for simple shear test.

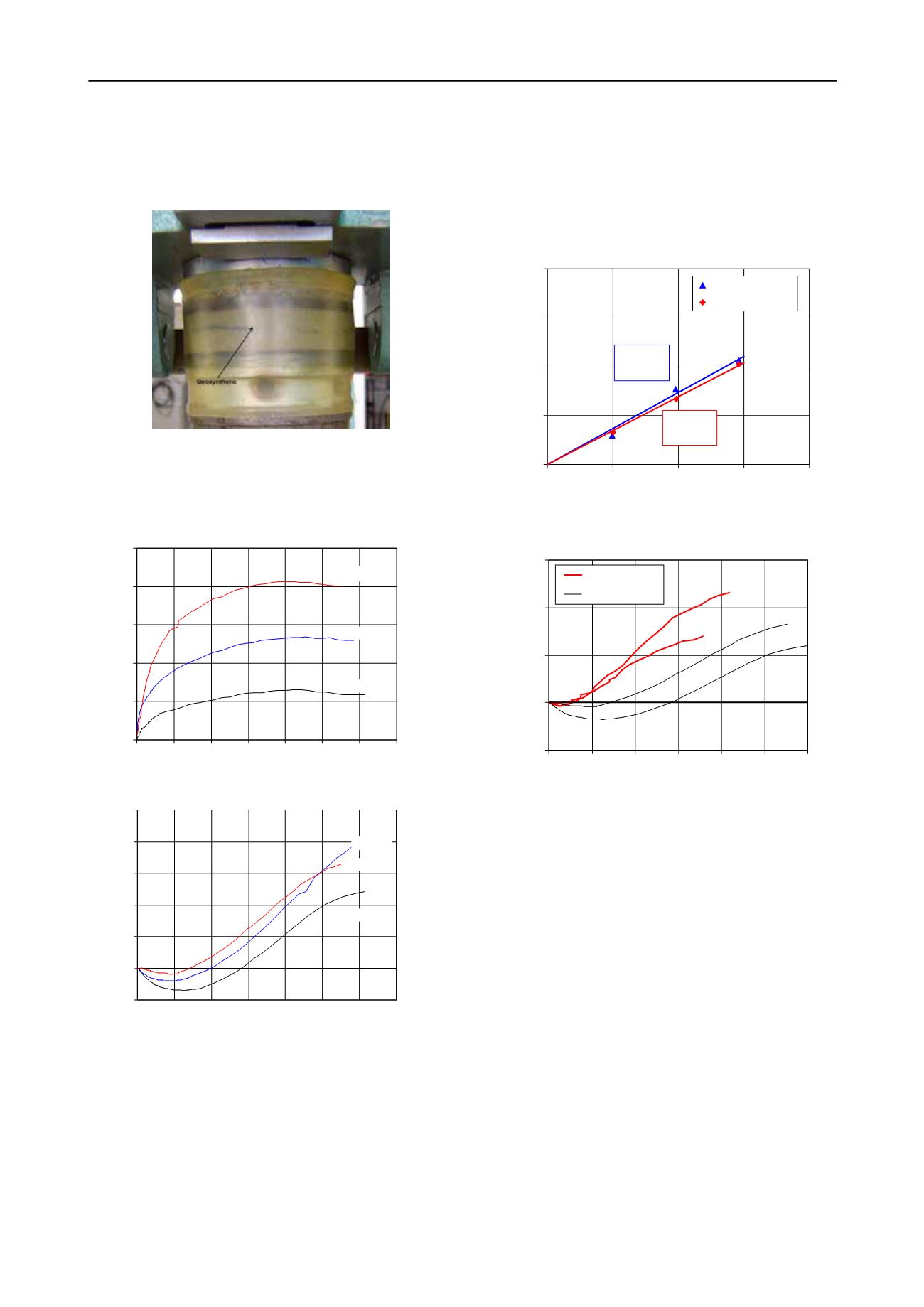

Figure 6 illustrates the shear stress

versus

shear strain

behaviour, as well as, the vertical displacement of the reinforced

sand specimen during shear.

0

25

50

75

100

125

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

δ

h

/H

0

Shear stress (kPa)

50 kPa

100 kPa

150 kPa

(a)

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

δ

h

/H

0

Vertical displacement (mm)

50 kPa

100 kPa

150 kPa

(b)

Figure 6. Simple shear tests results for reinforced sand: (a) shear stress-

shear strain behaviour; (b) vertical displacements during shear.

The maximum shear strengths for the three values of the

confining pressure and the failure envelopes for unreinforced

and reinforced sand are compared in Figure 7. Unexpectedly,

the shear strength of the reinforced sand tended to be lower than

the shear strength of the unreinforced sand. This evidence is

probably justified by the fact that the presence of the

reinforcement led to a looser layer of sand over the

geosynthetic, due to the damping caused by its presence during

the deposition process of the sand.

Figure 8 confirms the hypothesis above-mentioned. When a

reinforcement layer is placed within the specimen, greater

settlements (positive values of the vertical displacements) were

recorded and the dilatant phase had less significance. To

simplify the figure, it was decided to present only the vertical

displacements related to the tests performed with the highest

and lowest value of the normal stress.

τ

= 0.7381

σ

R

2

= 0.9757

τ

= 0.6932

σ

R

2

= 0.9961

0

50

100

150

200

0

50

100

150

200

Normal stress (kPa)

Shear stress (kPa)

Unreinforced sand

Reinforced sand

Figure 7. Comparison of the failure envelopes for unreinforced and

reinforced sand.

-0.6

-0.4

-0.2

0

0.2

0

0.05 0.1 0.15 0.2 0.25 0.3

δ

h

/H

0

Settlement (mm)

Unreinforced sand

Reinforced sand

150 kPa

50 kPa

150 kPa

50 kPa

Figure 8. Comparison of vertical displacements of the specimen in

simple shear tests on unreinforced and reinforced sand .

5 COMPARISON OF THE RESULTS

Prior to the comparison of the results achieved with the

developed large scale direct shear device and those obtained

with simple shear tests, it will be analyzed the scale effect of the

direct shear box on the sand-geotextile interface shear strength.

Regarding the influence of the dimensions of the shear boxes

on the test results, contradictory opinions can be found in the

literature. Palmeira (1988) stated that the scale effects do not

affect the peak value of the friction angle obtained from direct

shear tests. Hsieh and Hsieh (2003) found that, in general, the

shear strength obtained in shear boxes with large dimensions is

greater than that obtained with smaller shear boxes.

Notwithstanding the fact that the conventional direct shear

device can only accommodate small size specimens, which

might impose serious limitations in terms of reproducing real

conditions, direct shear strength for several interfaces obtained

with the developed device were compared by Vieira (2008) with

results achieved in a small (60 mm

×

60 mm) conventional

direct shear apparatus. Figure 9 presents the evolution of the

shear stress with the shear displacement, normalized by the

length of the box, obtained with the large scale and the

conventional direct shear devices for the interface under

analysis in this work.