3303

Technical Committee 210 + 201 /

Comité technique 210 + 201

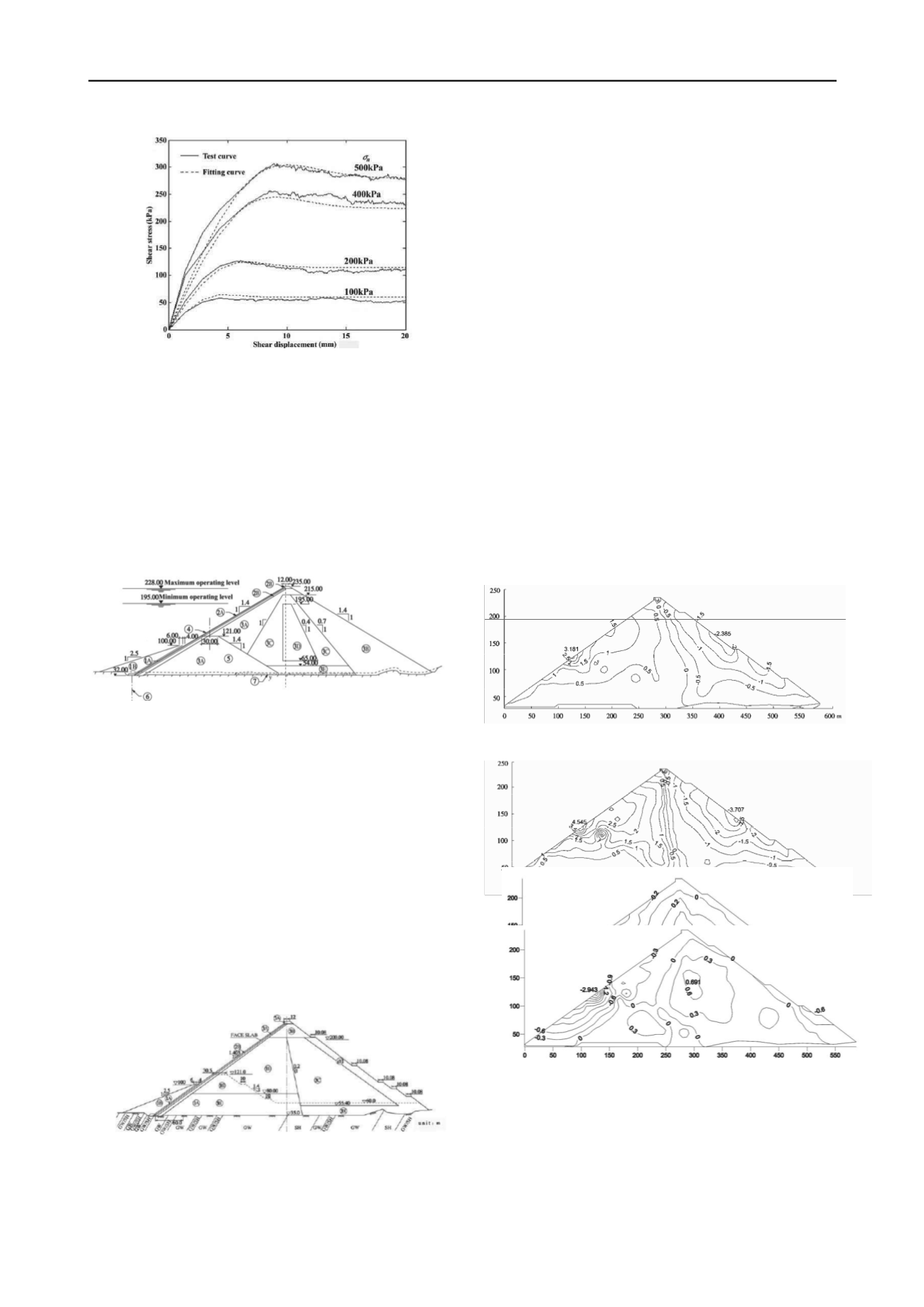

Figure1. Effectiveness of fitting contact surface model to contact

surface test result for Houziyan Dam

3. APPLICATION OF DEORMATION COORDINATION

DESIGN CONCEPT

The deformation coordination design concept has been applied

in Bakun Dam. Bakun Dam is located on Balui River, Sarawak

Malaysia. Bakun Dam is the second highest completed CFRD

in the world with its height 202m. The former design of Bakun

Dam was completed by H.S.Choi, Germany. The former dam

zoning of Bakun Dam is shown in Figure 2.

Figure 2 Zoning of Bakun Dam designed by empirical method (unit:

m)

Bakun CWZ-Main Civil works tender had been obtained by

Malaysia-China Hydro Joint Venture (MCH JV) in 2002.

Bakun Dam design has been completed by China Hydro

Northwest Investigation Design &Research Institute. Bakun

Dam filling material test and 3D FEM analysis has been

completed by Nanjing Hydraulic Research Institute. Based on

deformation coordination design concept a new dam zoning for

Bakun Dam has been put forward as shown in Figure 3.

The main difference between the former design and new

deformation coordination design are as follows: The dry mass

density of compacted rockfill is 2.09 g/cm

3

for the former and

2.22g/cm

3

for the latter. The water-stop of vertical joint of

concrete face slab is bituminizing plate for the former and

deformable Pulai Plate for the latter.

Figure 3 Zoning of Bakun Dam designed by new deformation

coordination concept (unit: m)

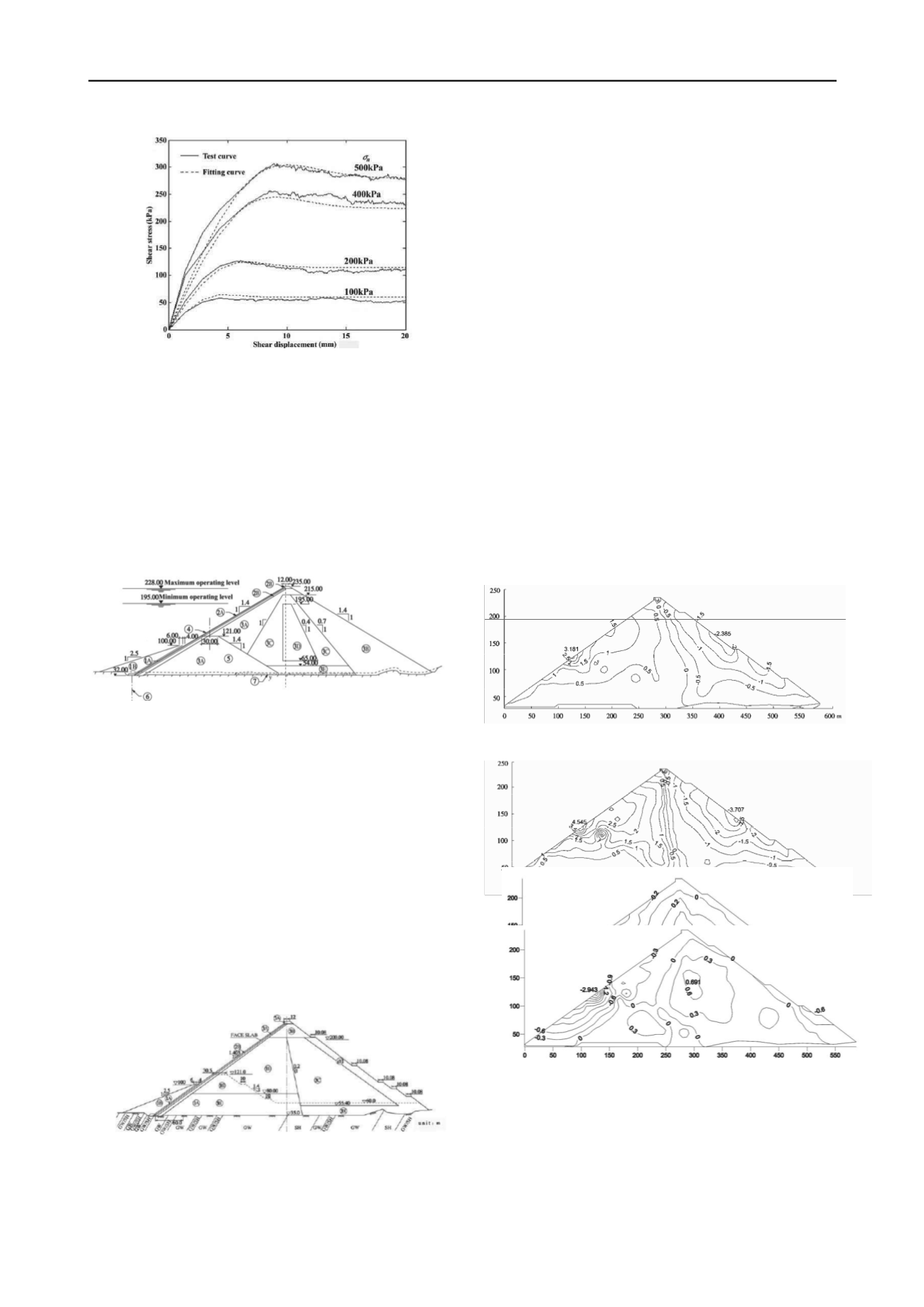

The results of 3D FEM analysis and the comparison of dam

behavior and deformation coordination level between the

former design and new design are shown in Figure 4 to Figure

6.

The maximum settlement of dam body at completion is

376.4cm for the former and 230.6cm for the latter. The

observed settlement is 227.5cm.The maximum displacement

towards downstream of dam body during impoundment is

79.2cm for the former and 48.9cm for the latter. The observed

displacement is only 13.0cm. The maximum deflection of face

slab at impoundment is 105.7cm for the former and 84.7cm for

the latter. The maximum compressive stress at dam axis

direction of face slab at impoundment is 19.2MPa for the

former and18.3MPa for the latter.

The following results could be obtained from Figures:

1

)

The dam deformation of dam body designed by

empirical concept is uncoordinated especially at cushion zone

and top of the first stage filling. Its maximum difference of dam

body settlement is 4.55

×

10

-2

(

Figure 4

)

, its maximum

difference of horizontal displacement of dam body is -2.94

×

10

-2

(

Figure 5

)

.Cracking of its cushion zone would occur

probably.

2

)

The maximum displacement difference at normal

direction between face slab and cushion designed by empirical

concept reaches 113.5cm. Its top of face slab would separate

from cushion and then cracks of face slab would occur

probably.

3

)

The maximum compressive strain at dam axis direction

of face slab designed by empirical concept is 670

×

10

-6

(

Figure

6

)

.which exceeded the limit of compressive stain

(

650

×

10

-6

)

from prototype data of Mohale Dam. In other words,

squeezed rupture of concrete face slab would occur probably.

(a)Settlement difference of Bakun Dam body designed by

deformation coordination method (unit:10

-2

)

(b)Settlement difference of Bakun Dam body designed by empirical

method (unit: 10

-2

)

Figure 4 Comparison of settlement difference of Bakun Dam at water

impoundment between empirical method designed and new deformation

coordination concept method designed

(a)Horizontal displacement difference of Bakun Dam body designed by

deformation coordination method (unit: 10

-2

)

(b)Horizontal displacement difference of Bakun Dam body designed by

empirical method (unit: 10

-2

)

Figure 5 Comparison of horizontal displacement difference of Bakun

Dam body at water impoundment between empirical method designed

and new deformation coordination concept method designed