2706

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

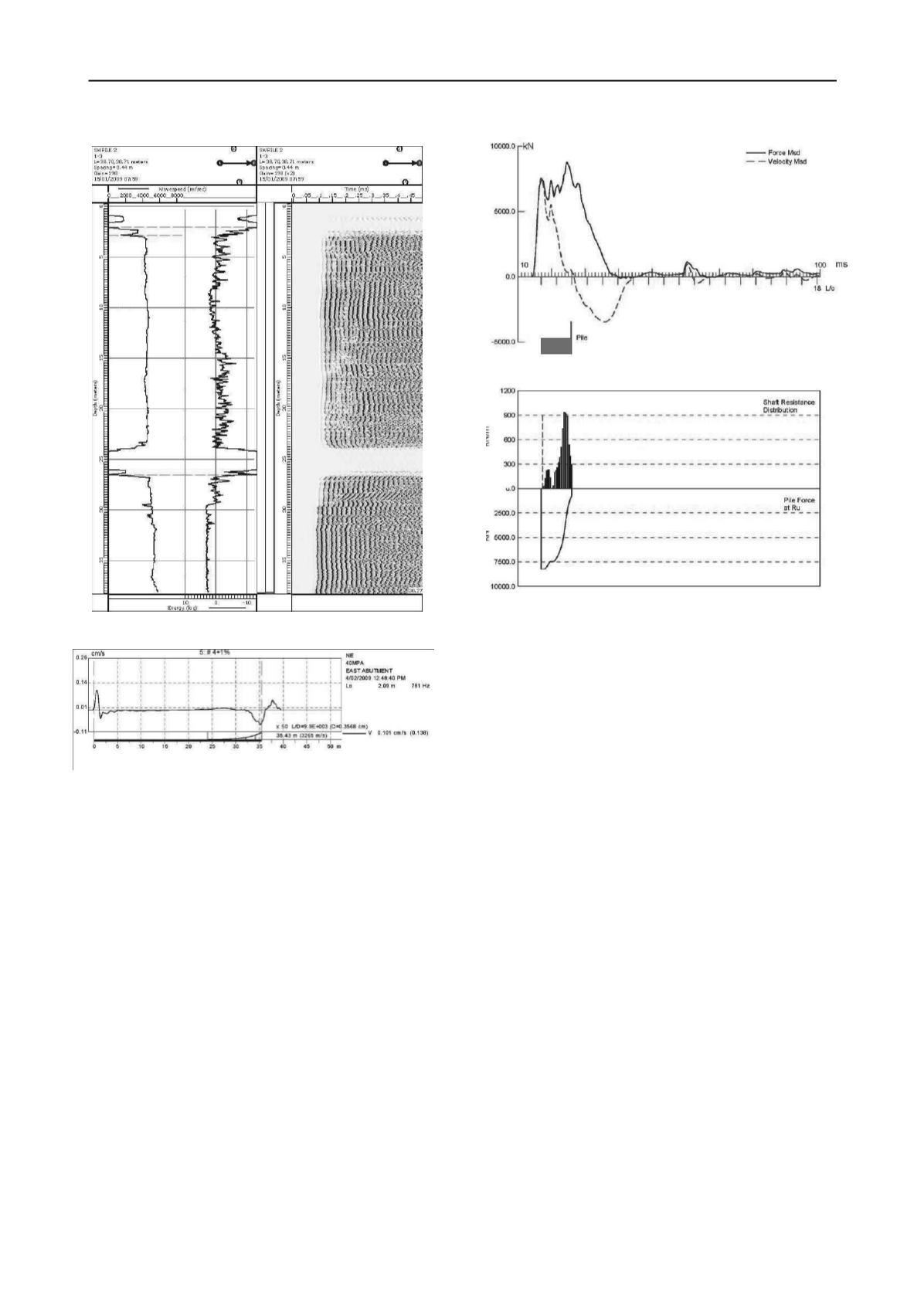

restrike was adequate for all pile positions - upstream,

downstream and longitudinal. (Figure 10).

The skin resistance distribution shown in the CAPWAP

®

appears to reduce toward the toe because at such small sets not

much of the energy of the input blow reached the lower part of

the pile and the reduced energy did not strain the ground enough

to generate the full resistance that was available. The available

resistance probably does not reduce. If the pile could have been

struck harder, then even more resistance would have been

demonstrated.

7. DRIVEN PRODUCTION PILES

It was considered the driven pile created a more reliable

foundation and repairs could be easily accomplished by re-

driving if necessary. A decision was made to change the

foundations for all piers from bored piles into driven piles. In

addition repairs for the abutment piles were also to be driven

piles.

The effect of this decision was to dramatically improve

production rates on the pile foundations. Because the concrete

was eliminated from the pile there were also considerable

savings over the original design.

Owing to the numerous problems experienced during initial

piling and the tripod design that provided no redundancy, the

client required that all driven piles undergo PDA testing.

Production testing was conducted remotely or by "stand-alone."

(Likins, Hermansson, Kightley, Cannon and Klingberg 2009)

The shorter piles at the western end of the bridge could be

tested with the smaller 9ton hammer, however from almost

exactly the centre of the bridge it was necessary to use the larger

16t hammer to demonstrate the required resistance. In some

cases it was necessary to wait for "set-up" and conduct restrikes

at 1-7 days after driving.

Tension resistance, particularly on upstream piles, was of

critical importance. In some cases the resistance demonstrated

by CAPWAP appeared to be heavily concentrated near the toe

and owing to concern about the ability of CAPWAP to

accurately differentiate between skin friction near the toe and

toe resistance the author was requested to provide an estimate of

the "minimum likely" skin friction. The method adopted was

purely arbitrary and comprised starting with "best match" and

moving skin friction to toe resistance until the match quality

increased by one percent, ie CAPWAP match quality increased

from 3.1 to 4.1 percent error.

8. CONCLUSIONS

Low strain and high strain dynamic pile testing was

incorporated into both the design revision and construction

verification aspects of this successful project.

During construction both high strain and low strain

dynamic testing demonstrated serious problems with the

"constructability" of the original bored pile design.

An innovative decision was made to radically change the

pile design, from a bored pile to a driven steel tube pile.

Dynamic pile testing was able to confirm pile resistance

and provide a high level of confidence in the foundation. The

bridge has been working as designed through 3 cyclone seasons

carrying some of the heaviest train axle loadings in the world.

9. REFERENCES

Likins, Hermansson, Kightley, Cannon and Klingberg 2009

Advances in Dynamic Foundation Testing Technology

IFCEE Orlando, Florida USA

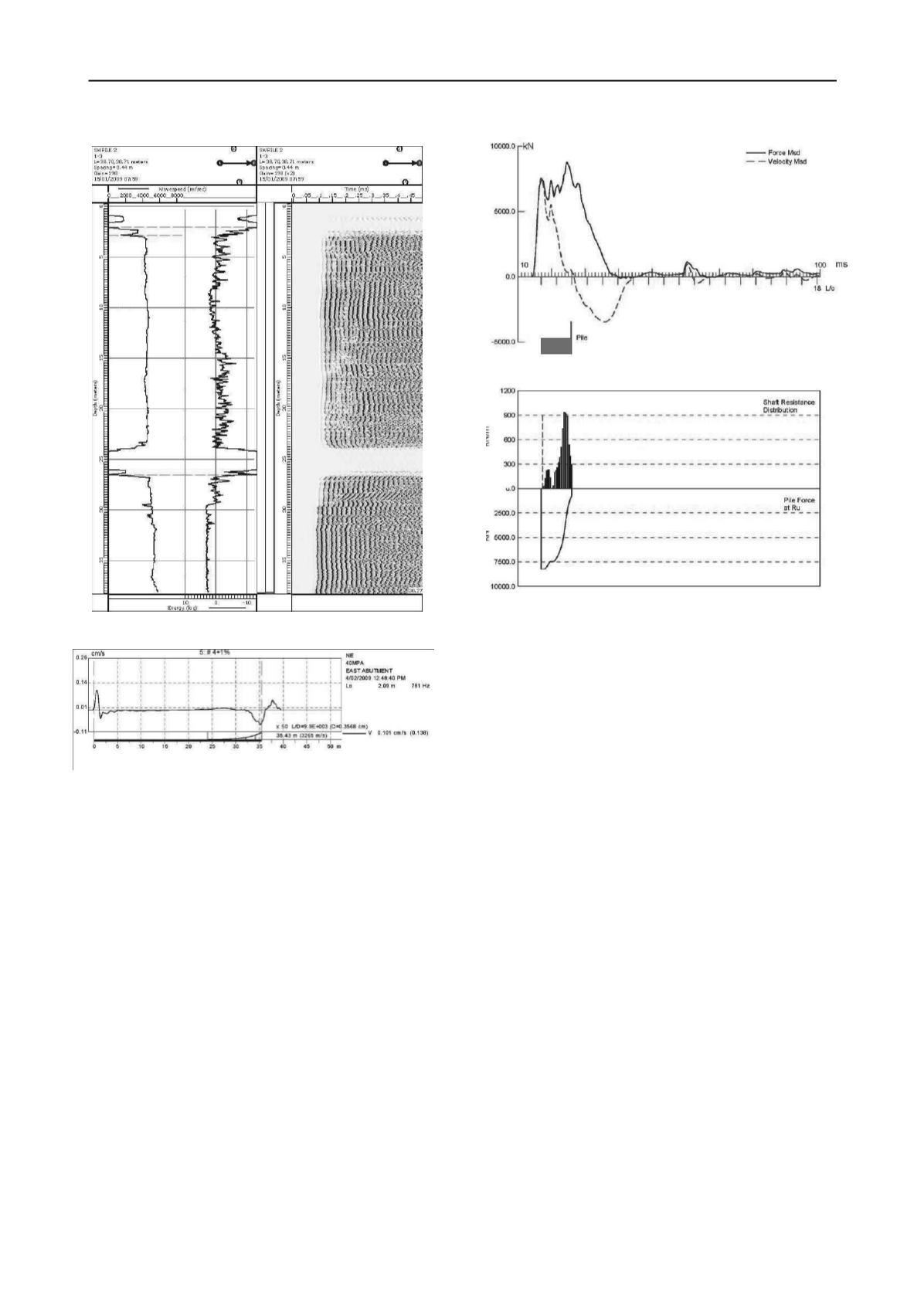

Figure 9 PIT results for East Abutment NW pile

Figure 10 CAPWAP results for Test Pile 3

Figure 8 CSL result on production pile