2705

Technical Committee 212 /

Comité technique 212

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

At the same time the author was requested to conduct

driveability predictions using wave equation analysis of piles

(WEAP) to assess if the casings could be used as driven piles.

One of the main criteria of interest was whether the piles could

be driven far enough into the soft rock to achieve the required

tension resistance, which was a controlling aspect of the tripod

foundation design. This appeared to be the case, and with a

smaller hammer than was being used for the dynamic testing.

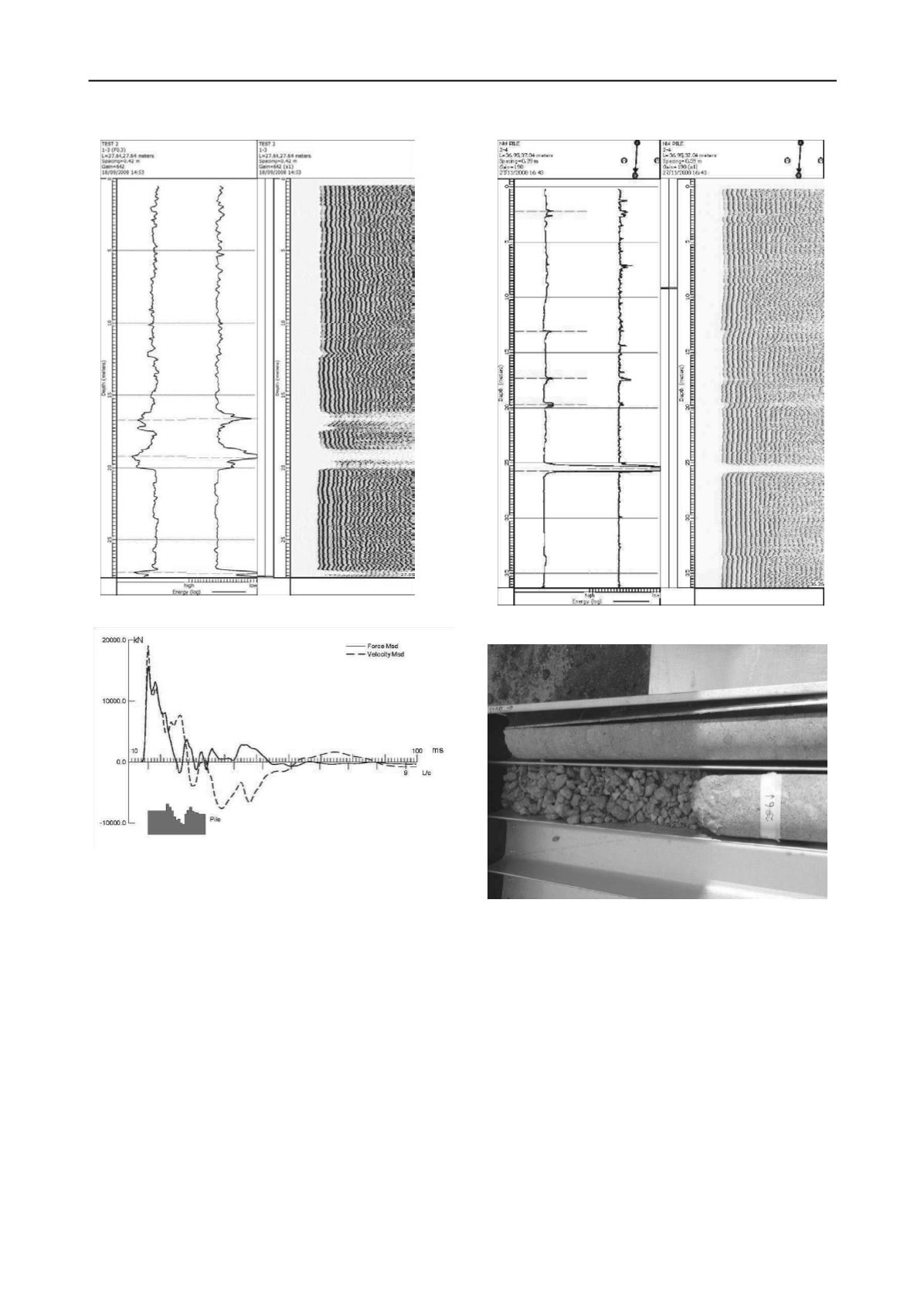

Construction started on the East Abutment and, again,

problems with the concrete quickly became obvious. CSL

testing indicated a significant defect at 25m below the top.

(Figure 6). Drill cores were conducted to investigate and repair

the problem zone. Coring confirmed a zone of aggregate only

with no cement - exactly as predicted by the CSL. (Figure 7).

Further attempts were made to improve the concrete but in

every case problems were detected. If anything the concrete

problems got worse, both in size and significance. (Figure 8).

Prior to the abandonment of socketed piles one further test

was conducted on the last socketed abutment pile. No access

tubes had been cast in this pile so low strain axial sonic pile

integrity testing using a Pile Integrity Tester

®

(PIT) was

conducted (Figure 9). No integrity problems were detected

using this method. A very slight increase in velocity was

detected at the top of the socket but this was attributed to the

change in diameter from 900mm to 780mm.

6 DRIVEN TEST PILE

Soon after the WEAP analyses were conducted a third test pile

was installed. Again, this was positioned adjacent to the bridge

location and was not to be incorporated into the contract works.

The 900x20mm steel tube casing was modified by removing the

bottom collar and installing a 900x50mm driving shoe of 0.8m

length. This third test pile was driven with a Junttan HHK9A

hammer, which has a 9t ram. The pile was driven through the

gravels and cobbles and 12m into the soft rock at a final set of

2.9mm/bl. A restrike test was conducted the next day using the

Junttan HHK16A hammer, which has a 16t ram. The pile had

"set-up" to such an extent the set had reduced to 1.3mm/bl

despite the hammer being significantly larger than the hammer

used to drive the pile. The resistance demonstrated during the

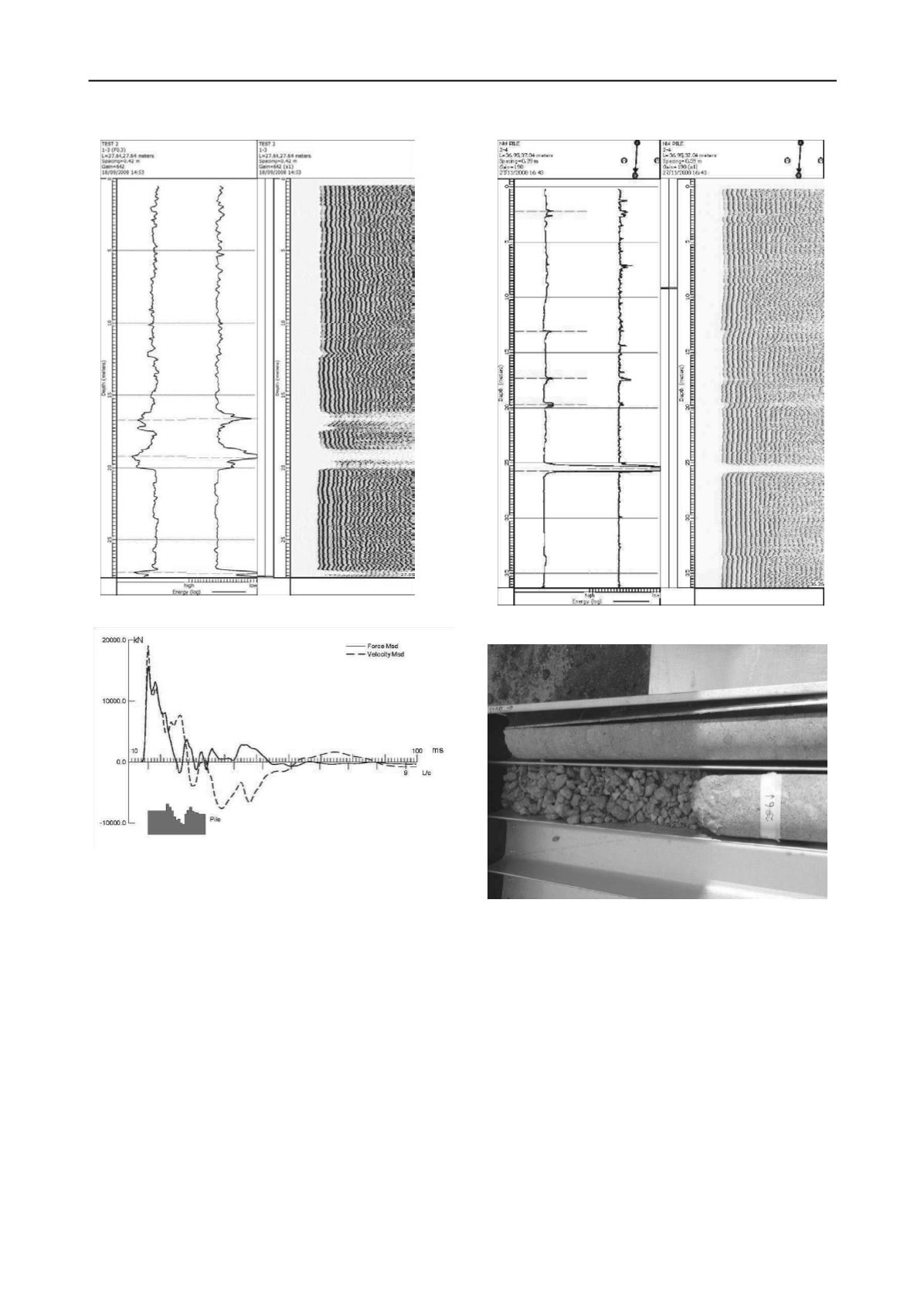

Figure 5 - PDA measurements Test Pile 2

Figure 4 - CSL test results Test Pile 2

Figure 7 - Core of East Abutment NW pile

Figure 6 CSL test result East Abutment NW pile