2704

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The piles were 900mm OD with 20mm wall thickness steel

tubes with a concrete socket in the rock. At this site the socket

was 780mm diameter. The concrete was to be continued into

the pile a sufficient distance to transfer the load by

steel/concrete bond - about 8m. The concrete was to be heavily

reinforced owing to high tension loading, with ten clusters of

three 36mm diameter bars.

The contractor initially installed the casings with a large

down-the-hole hammer. This used a 940mm hammer

positioned at the bottom of the excavation and powered by

compressed air. The hammer drags the casing behind it by

engaging a collar at the bottom of the casing. Upon reaching

rock the hammer can disengage the casing and bore a socket.

At this site the hammer was removed after reaching the rock

and a 780mm rock-roller drill was used to drill the socket. The

method was well known to the contractor and is reputed to have

excellent production rates in hard ground. However, at this site

the gravels and cobbles were loose and saturated. There was

frequently insufficient resistance to start the hammer and it

stalled frequently.

Progress was slow and delays were

extensive.

Owing to the remote site concrete was produced by a mobile

batch plant at the site but was otherwise unremarkable. The

piles were concreted using a tremie pipe with the shaft full of

water or drilling fluid.

4

SOCKETED TEST PILES

The first pile constructed at the site was a test pile that was not

to be incorporated into the bridge. It was a vertical full sized

pile. To provide for dynamic testing the socket concrete was

extended to the top of the pile. The test gauges were initially

attached to the concrete through "windows" in the steel tube and

the pile was considered as a combined section. The top of the

steel tube was cut back 25mm below the top of concrete to

ensure the hammer acted on the concrete. A 19mm plywood

cushion was used between the hammer and the pile.

Other than the permanent casing there was nothing

unusual about the dynamic testing. Concreting had been

completed about 14days prior to the test.

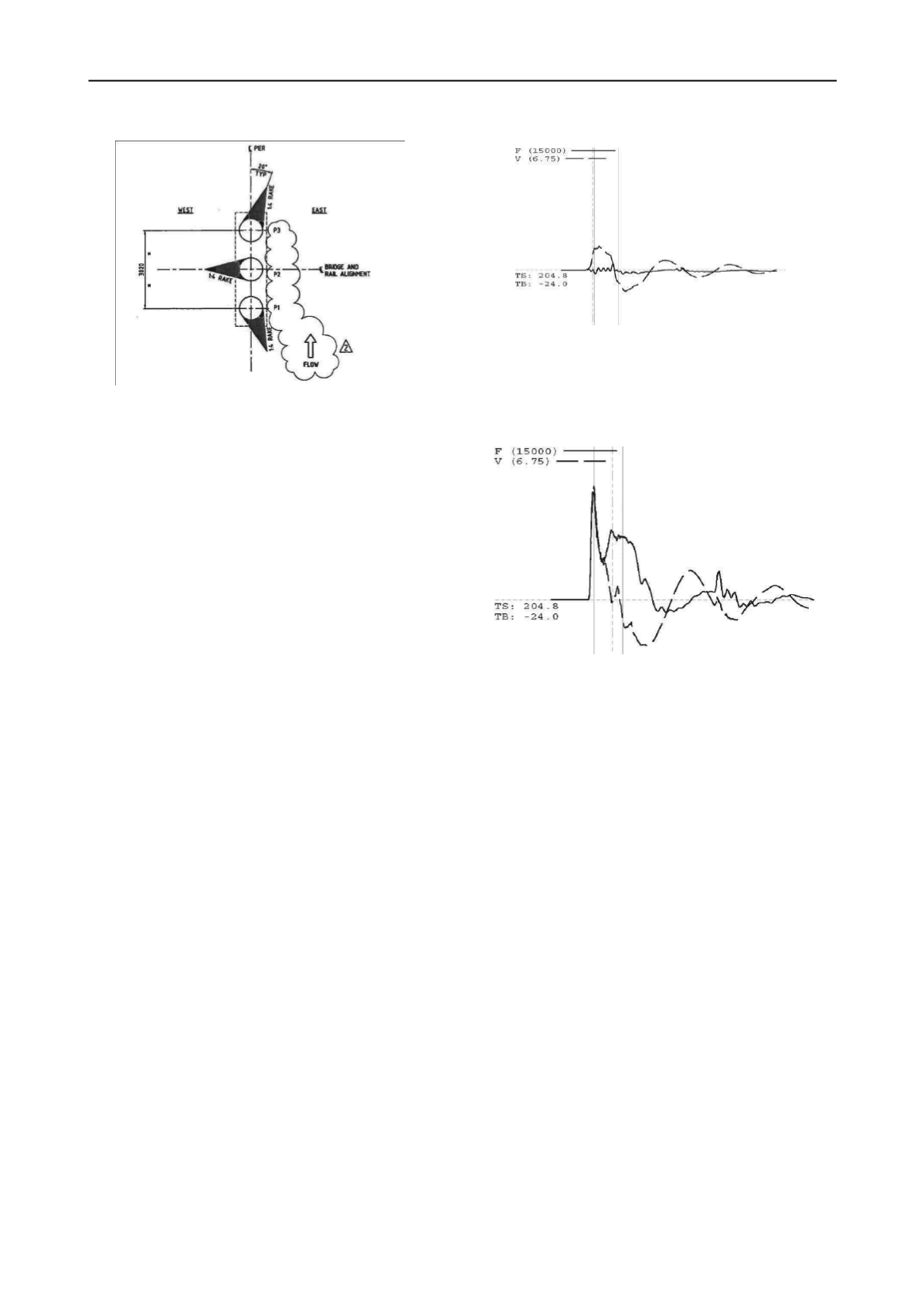

Very strange measurements were obtained initially, with

almost no force measured in the concrete. (Figure 2). In

addition it was observed after several blows that the concrete in

the "window" had moved down relative to the steel.

The gauges were moved to the steel tube and again very

strange measurements were obtained The only way the

measurements made sense was to use the properties of the steel

tube only and assume the concrete was not working as part of

the pile. (Figure 3). The hammer was removed and it was

noted the top was level with the steel. The hammer was indeed

acting on the steel tube.

The concrete between the pile top and the gauges must

have crushed by up to 44mm, being the 25mm upstand of

concrete plus the thickness of the pile cushion. The hammer

was replaced, with increased cushion, and more blows were

applied with no improvement of the measurements and with

further crushing of the concrete.

A second test pile was constructed and this time access

tubes for CSL testing were cast in the pile. Concreting records

showed potential problems near the toe and part way though the

pour. Observations suggested the concrete had started to set

early, possibly due to the extreme temperatures. CSL test

results confirmed problems at the toe and between 15-20m

below the pile top. (Figure 4).

Dynamic pile testing was also conducted and confirmed

concrete problems. Gauges were attached to the concrete

through windows in the steel casing. Results suggested there

was a significant defect 15-20m down the shaft. The steel was

also not contributing to the pile. Transfer of load by steel to

concrete bond seemed unreliable. (Figure 5).

5

PRODUCTION SOCKETED PILES

As it was thought the cause of the concrete problems was

known, and related to temperature and the behaviour of concrete

additives, it was decided to proceed with production piles, but

only at abutments, where repairs such as additional piles were

possible.

Figure 3 PDA measurements on steel

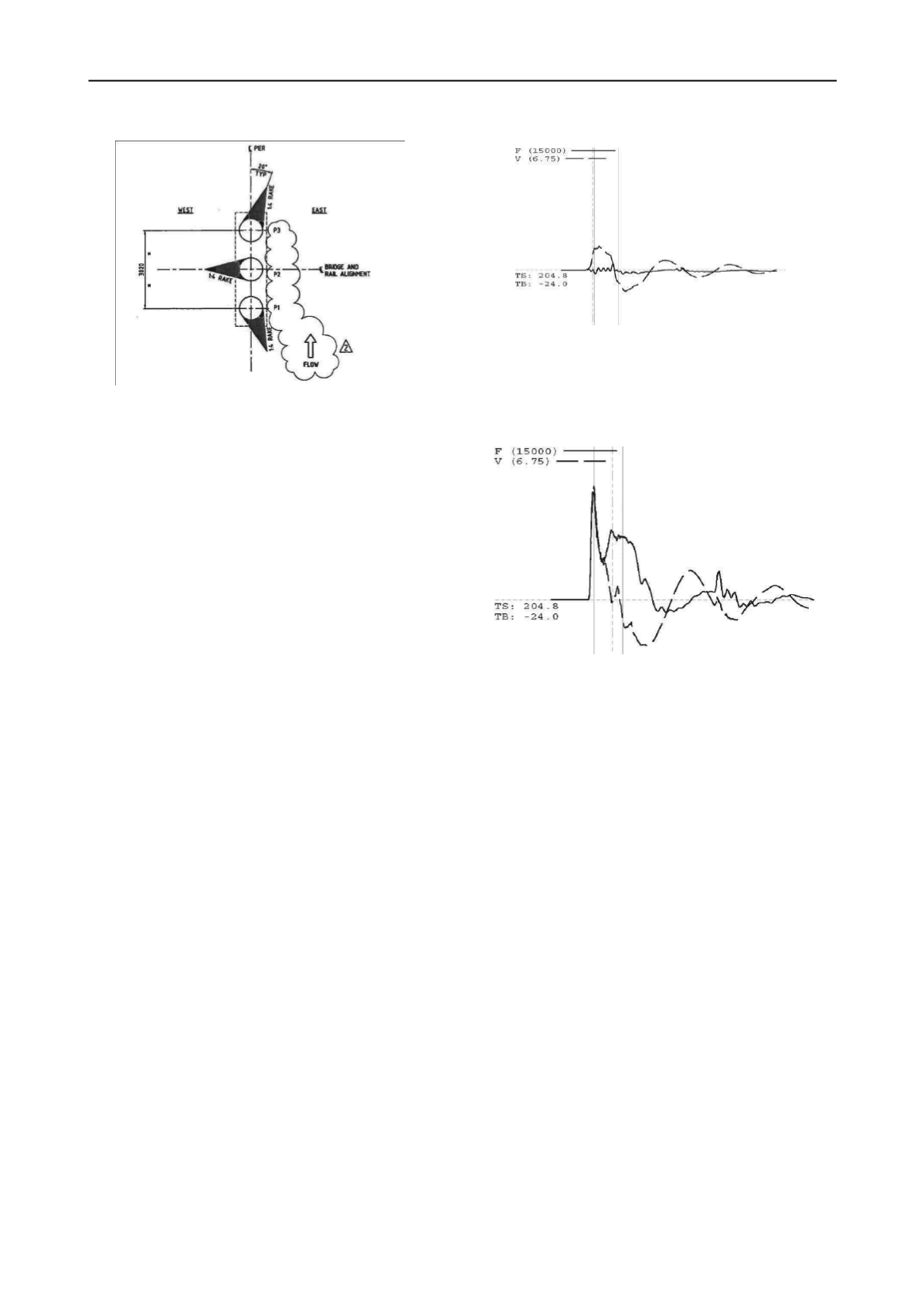

Figure 1 - Pier foundation Layout

Figure 2 - PDA measurements on concrete