3204

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

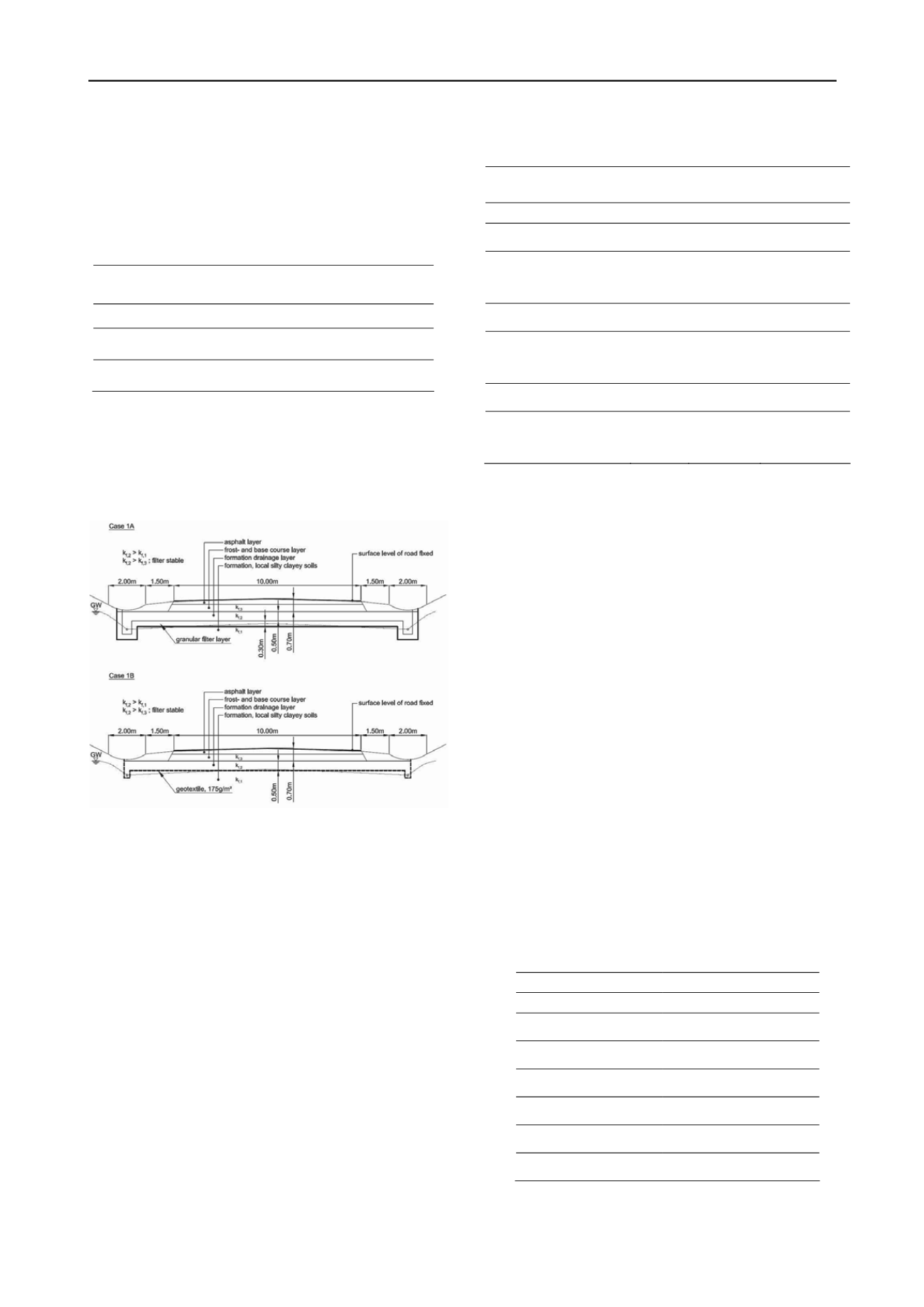

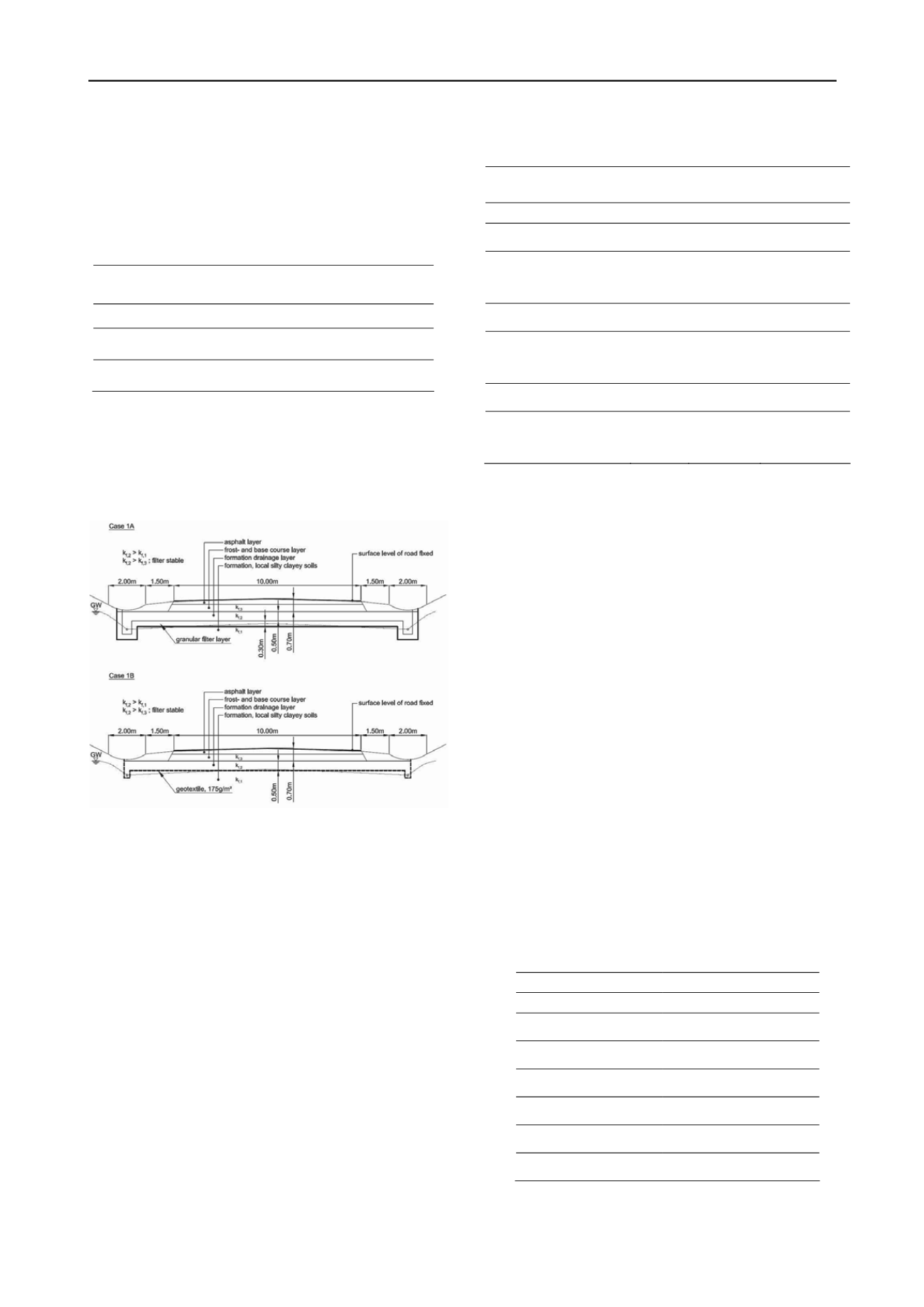

The way of the construction of the filter depends on several

factors. The basic conditions are shown in Tab. 1 and Fig. 1.

The two alternative cases compare the environmental impacts

of one square meter of the filter area below the road. The

additional excavation needed at the boundary area of the

mineral filter is not considered in the comparison.

Table 1. Design criteria of the two filter systems.

Parameter

Unit

Gravel

filter

Geosynthetic

filter

Filter size

m

2

1

1

Filtration geosynthetic

g/m

2

0

175

Gravel

cm

30

0

From these parameters it is calculated that the required

thickness D of the mineral filter is 300 mm and the one with

the geosynthetic filter layer is 1-2 mm. Fig. 1 shows a cross

section of the filter profile as modelled in this LCA.

In a sensitivity analysis the thickness of the gravel filter is

varied by +/- 10 cm.

Figure 1. Cross section of the mineral filter (top) and geosynthetic

filter system (bottom)

The functional unit in the comparative LCA is the provision

of 1 m

2

of filter with a hydraulic conductivity (k-value) of

0.1 mm/s or more and an equal life time of 30 years.

The difference between the two cases lies in the amount of

primary gravel used, the energy consumption that is related to

the filter material used (material transportation, excavation

etc.), and the use of geosynthetics. Recycled gravel is not

considered for the filter system since no onsite recycled

gravel is available when building a filter for the first time.

Some important key figures of the construction of the filter

systems are summarized in Tab. 2. The information refers to

one square meter filter and a life time of 30 years. The figures

shown regarding the particulate emissions refer to emissions

from mechanical processes (e.g., pouring, compacting of

gravel). Direct land use is not included in this LCI because

the type of land use under which the filter is being built in is

not known.

Table 2. Selected key figures describing the two constructions

f one square meter of filter

o

Material/Process

Unit

Gravel

filter

Geosynthetic

filter

Gravel

t/m

2

0.69

0

Geosynthetic layer

m

2

/m

2

0

1

Diesel

used

in

building machines

MJ/m

2

2.04

1.04

Transport, lorry

tkm/m

2

34.5

0.035

Transport,

freight,

rail

tkm/m

2

0

0.07

Particulates, >10 µm

g/m

2

4.8

0

Particulates, >2.5 µm

& <10 µm

g/m

2

1.3

0

3 MANUFACTURING OF THE GEOSYNTHETIC

LAYER

Data about geosynthetic material production are gathered at

the numerous companies participating in the project using

pre-designed questionnaires. The company specific life cycle

inventories are used to establish average life cycle inventories

of geosynthetic material.

The data collected include qualitative information of system

relevant products and processes from the producer,

information from suppliers of the producer (where possible)

as well as data from technical reference documents (e.g.

related studies, product declarations, etc.). Average LCI are

established on the basis of equally weighted averages of the

environmental performance of the products manufactured by

the participating companies.

The primary source of background inventory data used in this

study is the ecoinvent data v2.2 (ecoinvent Centre 2010),

which contains inventory data of many basic materials and

services.

In total, data from 13 questionnaires concerning the

production of geosynthetic layers used in filter applications

are included. The quality of the data received is considered to

be accurate. The level of detail is balanced in a few cases

before modelling an average geosynthetic layer.

Tab. 3 shows important key figures of the production of an

average geosynthetic layer.

Table 3. Selected key figures referring to the production of

kg geosynthetic layer used in filter applications

1

Material

Unit

Value

Raw materials

kg/kg 1.05

Water

kg/kg 2.16

Lubricating oil

kg/kg 0.0026

Electricity

kWh/kg 1.14

Thermal energy

MJ/kg 1.49

Fuel for forklifts

MJ/kg 0.09

Factory building

m

2

/kg 2.51E-5